Telescopic filter

A filter and telescopic technology, applied in chemical instruments and methods, magnetic separation, solid separation, etc., can solve the problems of shortening the service life of the filter element, wasting the resource of the filter element, and difficult to align the threaded holes, etc., so as to reduce the risk Hidden dangers, easy replacement and inspection, and easy disassembly

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] The filtered liquid in this embodiment is hydraulic oil.

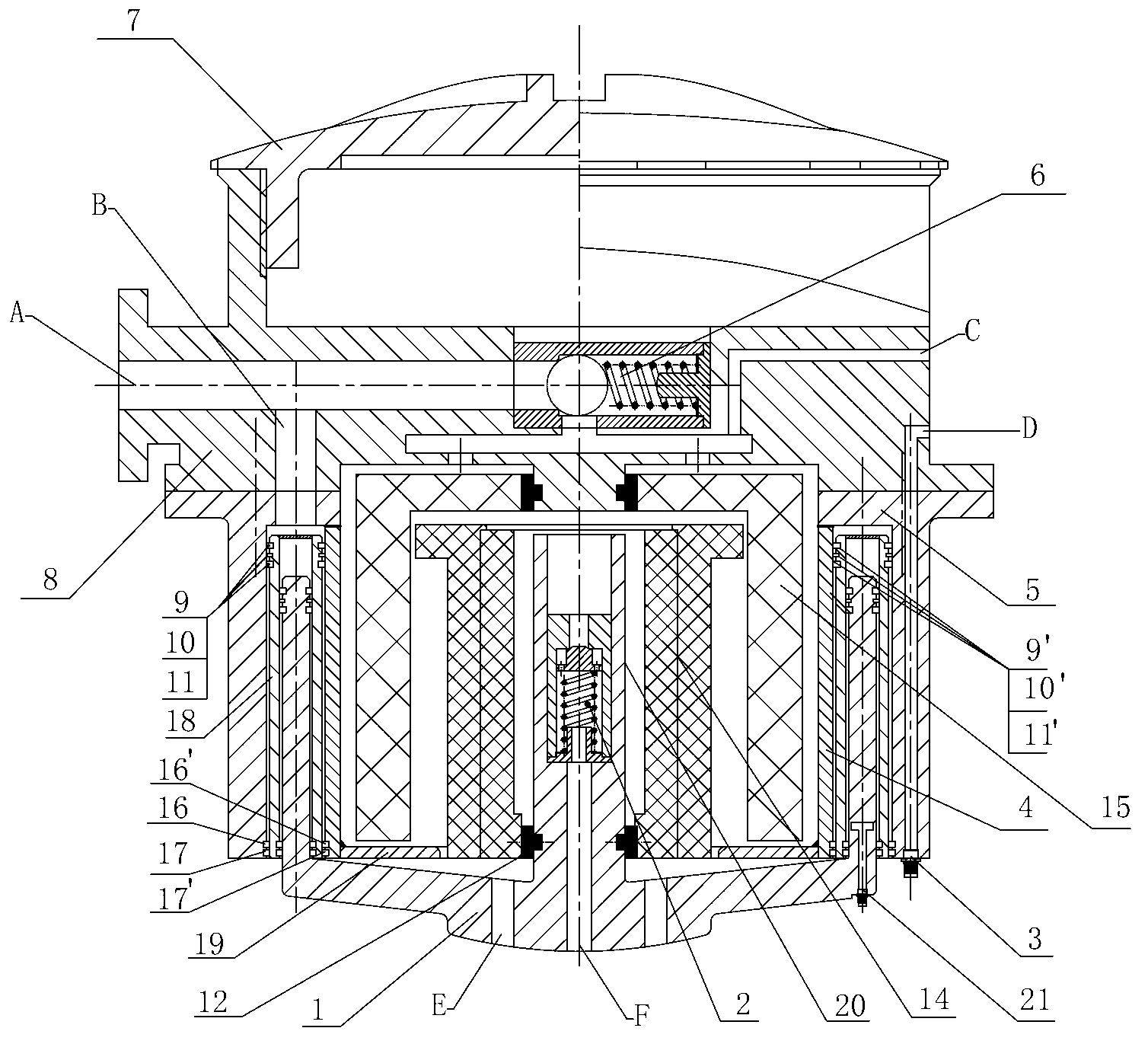

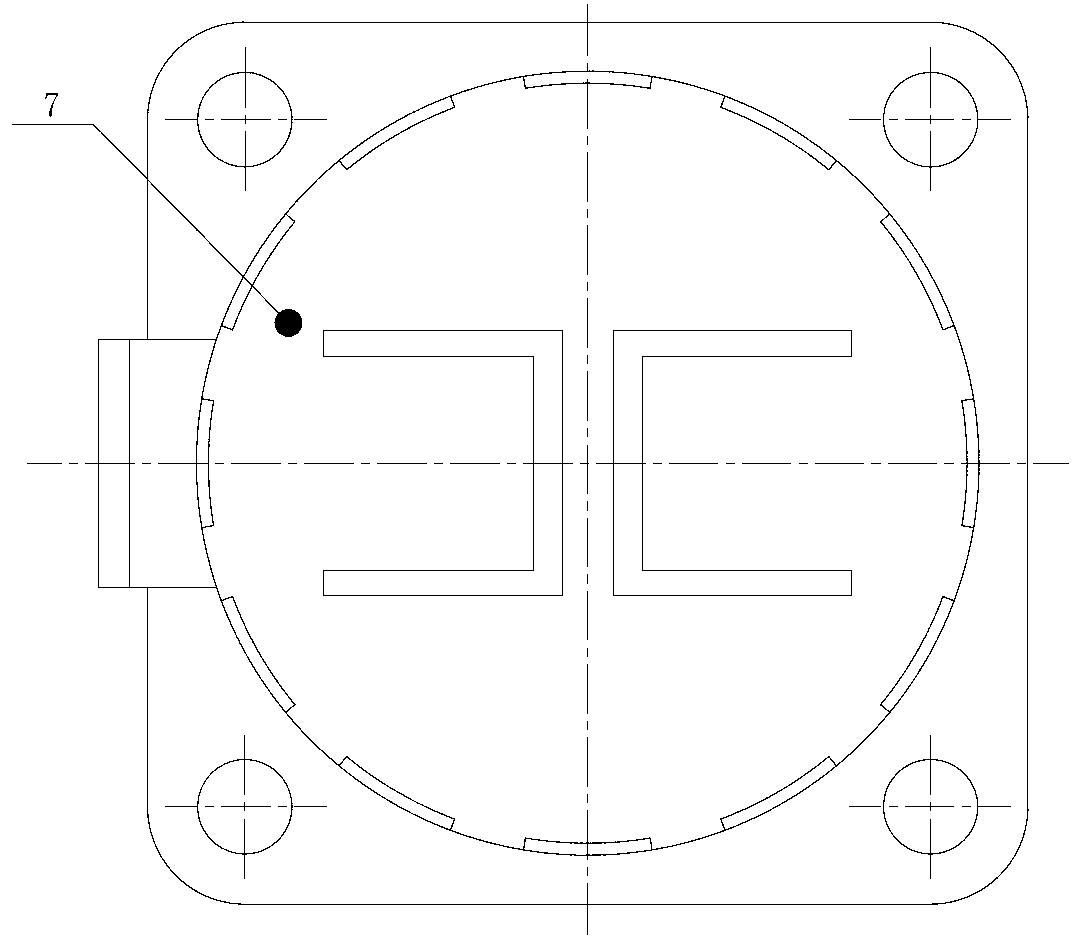

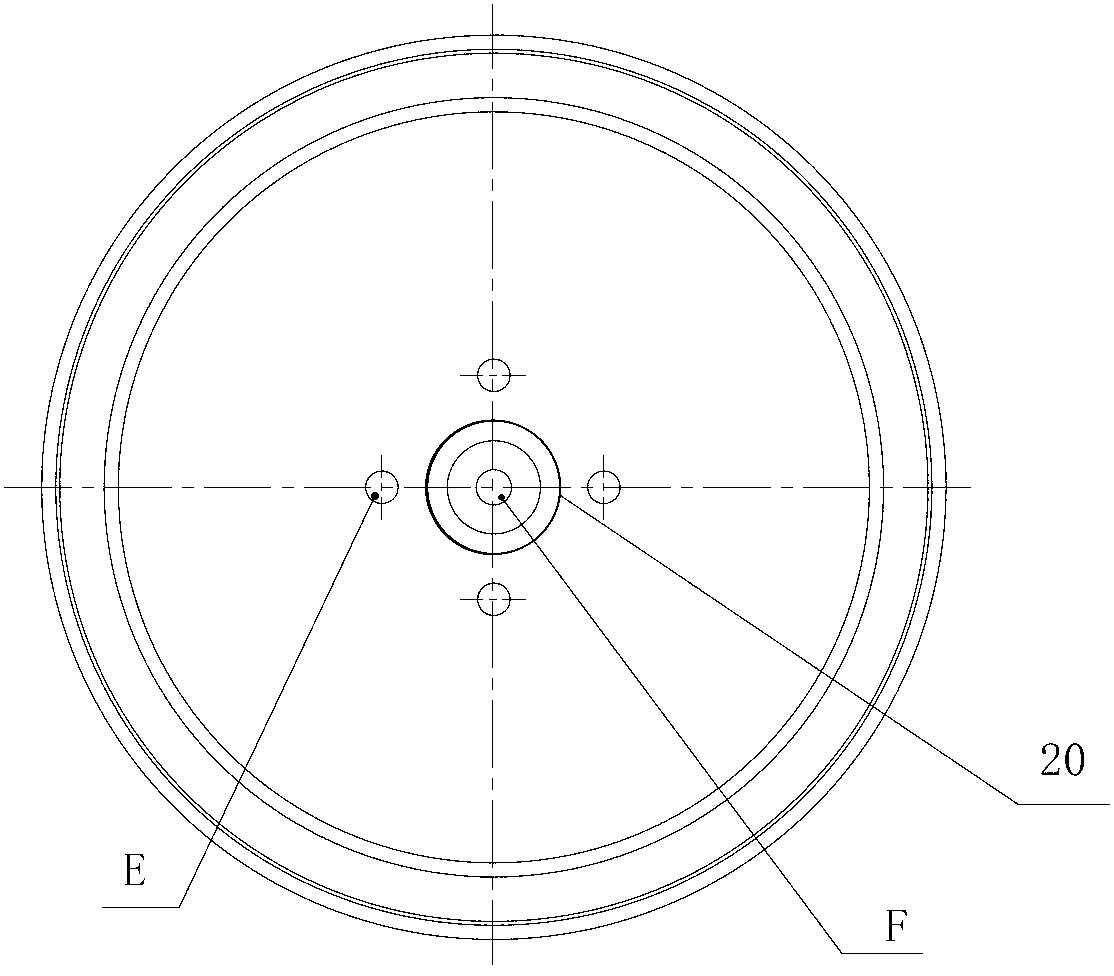

[0033] Such as Figure 1 ~ Figure 4As shown, the telescopic filter is composed of the third stage 1 of the filter, the bypass valve 2, the hose joint 3, the inner sleeve 4, the lower part of the first stage of the filter 5, the one-way valve 6, the end cover 7, the second stage of the filter First-stage upper part 8, inner and outer guide rings 9'9, inner and outer sealing rings 10'10, inner and outer upper guide bushes 11'11, inner and outer sealing retaining rings 12, paper filter element 14, mesh filter element 15, inner and outer key 16' 16. It is composed of inner and outer guide bushes 17'17, second stage of filter 18, circular baffle 19, middle magnetic rod 20, hose joint 21, etc., in which inner and outer guide rings 9'9, inner and outer sealing rings 10'10 The inner and outer upper guide bushes 11'11 constitute the guide seal positioning link, the inner and outer inner snap keys 16'16 and the inner and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com