A special-shaped gradual exhaust structure with low flow pressure loss

A low-flow, special-shaped technology, applied to engine components, machines/engines, and leakage prevention, to achieve the effects of reducing flow mixing losses, improving efficiency and reducing excessive structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

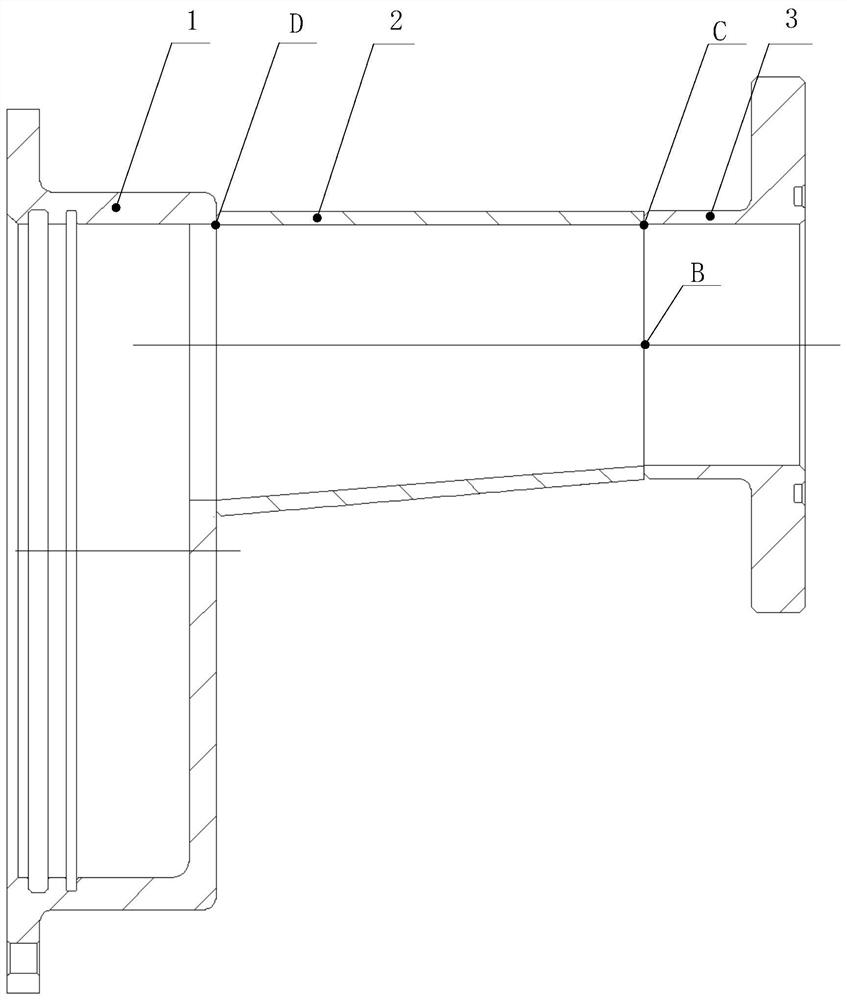

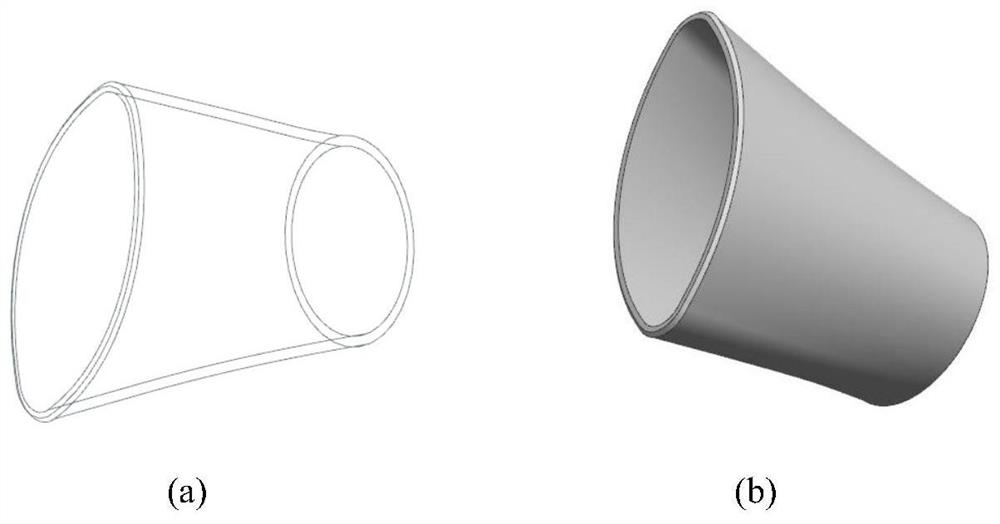

[0029] The low-flow pressure loss special-shaped gradual exhaust structure proposed by the present invention is composed of a gas collection shell, a special-shaped gradual change exhaust pipe, and an exhaust shell flange, such as figure 1 As shown, the gas collection shell, the special-shaped gradual exhaust pipe, and the flange of the exhaust shell are sealed and connected by welding. The gas collection shell is connected to the casing of the nozzle box of the steam turbine through 6 bolts. High-temperature asbestos pad seal, the exhaust shell flange is connected with the condenser gas distribution flange through six bolts and sealed with a copper pad.

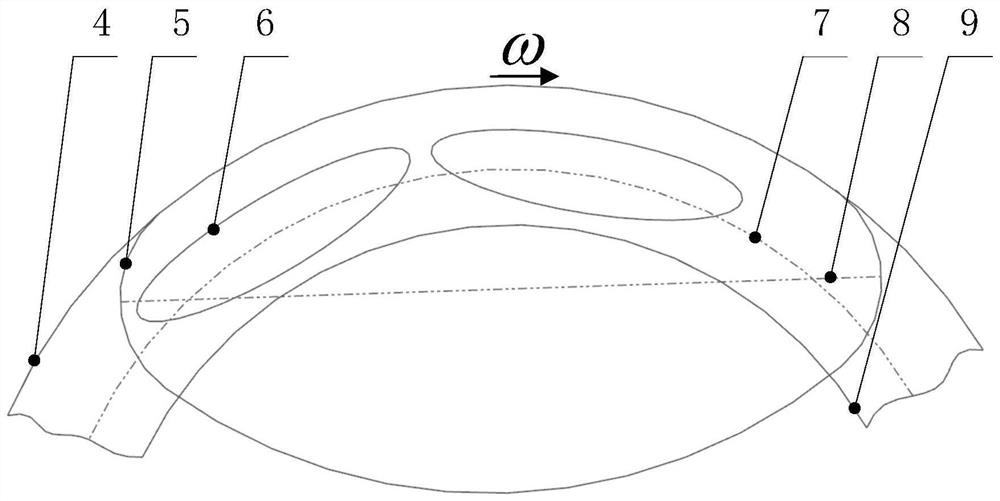

[0030] The working principle of the present invention is: after the high-temperature and high-pressure steam expands and accelerates through the zoom nozzle of the steam turbine, it flows out at a high Mach number and ultra-high speed, and a part of the steam maintains a high-speed state and directly impacts the special-shape...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com