Tobacco flavor and perfume quality analysis method

A technology of quality analysis and tobacco flavor, applied in the field of tobacco, can solve the problems of product quality fluctuations, the inability to objectively and accurately reflect the internal chemical quality and quality fluctuations of the feed liquid, and the inability to meet the requirements of refined production management, etc., to achieve accurate measurement Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0028] Example 1 Flavoring essence sample for tobacco

[0029] In accordance with the provisions of Part 10 "Sampling of Tobacco Flavors and Fragrances" in the tobacco industry standard YC / T145.10-2003, samples of flavored flavors were sampled, and five types of samples were taken in total, with a total of 186 batches (13 randomly selected Fragrance flavor samples as verification samples).

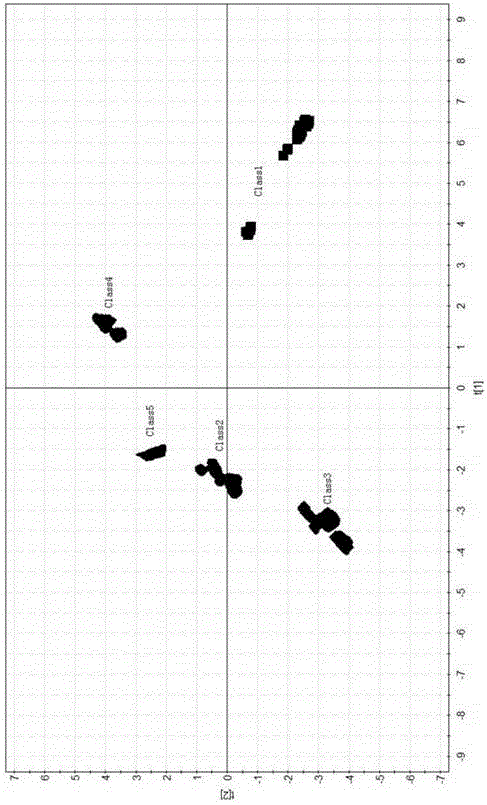

[0030] Take 1g of the flavoring essence sample for tobacco and dilute it to 10mL with absolute ethanol, pass through a 0.4μm filter membrane, and perform GC / MS analysis to obtain the chromatographic fingerprint of the flavoring essence sample for tobacco (see figure 1 ).

[0031] Perform data processing on the fingerprints of the known types of tobacco flavors and fragrances, including baseline drift, noise processing, peak drift correction, peak resolution, analysis, etc., so that the fingerprint data collection meets the modeling requirements. The collected fingerprints were analyzed f...

Embodiment 2

[0037] Embodiment 2 flavoring essence sample for tobacco

[0038] According to the provisions of Part 10 "Sampling of Tobacco Flavors and Fragrances" in the tobacco industry standard YC / T145.10-2003, samples of flavoring flavorings were sampled, and two types of samples were taken in total, with a total of 72 batches (10 flavorings were randomly selected) Flavor samples as verification samples).

[0039] Accurately weigh 0.500 g of flavoring flavor sample for tobacco into a thermal desorption tube (4 mmi.d. × 178 mmL) for TDS-GC / MS analysis. Obtain the chromatographic fingerprint of cigarette flavoring essence sample (see Figure 5).

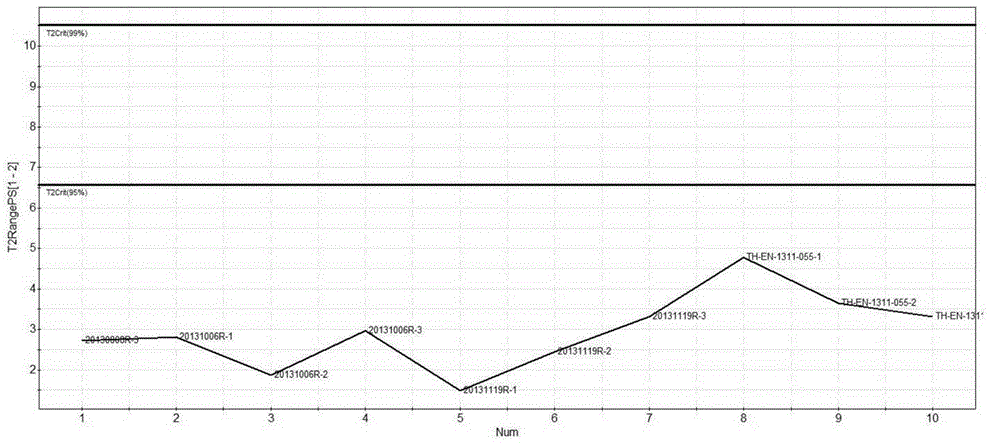

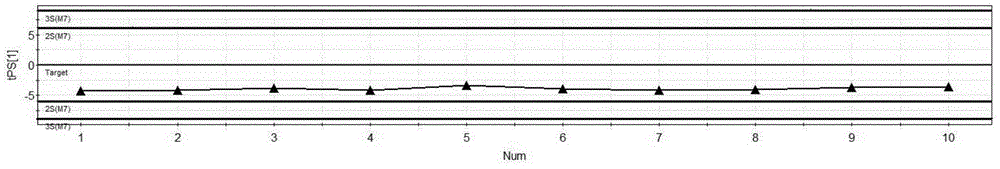

[0040] Perform data processing on the fingerprints of the known types of tobacco flavors and fragrances, including baseline drift, noise processing, peak drift correction, peak resolution, analysis, etc., so that the fingerprint data collection meets the modeling requirements. The collected fingerprints were analyzed for components.

[0041]...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com