A method for strengthening pre-impregnation of chemical thermomechanical pulp

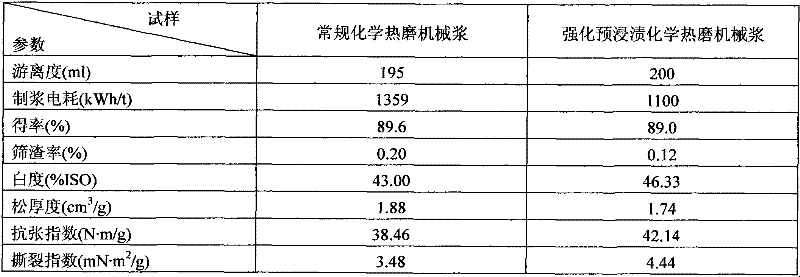

A chemical thermomechanical and chemical impregnation technology, applied in pulp beating/refining method, pulping with inorganic alkali, pulping with organic solvent, etc. Work load, affecting pulp quality and other problems, to achieve the effect of improving pulp quality, reducing refining energy consumption, and simple process transformation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

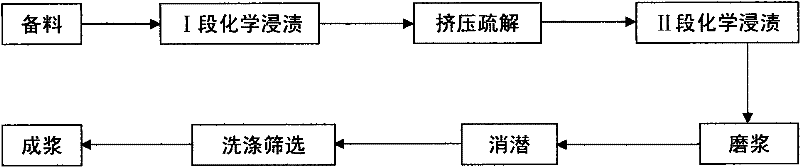

[0022] The process condition of triploid poplar tomentosa adopting enhanced pre-impregnation chemical thermomechanical pulping method: get triploid poplar tomentosa wood chips 2kg (dry); I stage chemical pre-impregnation, NaOH consumption 1%, penetrant consumption 0.2%, The solid-liquid ratio is 1:3, the temperature is 90°C, and the immersion time is 40 minutes; the compression ratio is 4:1; 2 SO 3 The dosage is 3%, the dosage of penetrant is 0.2%, the solid-liquid ratio is 1:4, the temperature is 120°C, the soaking time is 30min; three-stage refining, the concentration is 30%, the disc grinding gap is 1.5mm→0.4mm→0.1mm; , temperature 80°C, time 30min; screening, sieve gap 0.15mm.

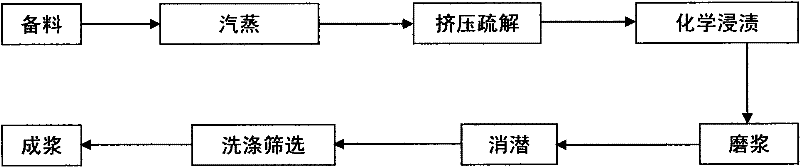

[0023] The technological conditions of adopting conventional chemical thermomechanical pulping method for triploid Populus tomentosa: get 2kg (dry) of triploid Populus tomentosa wood chips; steam at normal pressure for 15min; extrude and decompress, compression ratio 4: 1; NaOH dosage 3%, Na 2 S...

Embodiment 2

[0030] Eucalyptus wood adopts the process condition of strengthening pre-impregnation chemical thermomechanical pulping method: get eucalyptus wood chips 2kg (dry); I section chemical pre-impregnation, NaOH consumption 1.5%, penetrant consumption 0.3%, solid-to-liquid ratio 1 : 3, temperature 90°C, immersion time 40min; extrusion defrosting, compression ratio 4:1; stage II chemical impregnation, NaOH dosage 2.5%, NaOH 2 SO 3 The dosage is 3%, the dosage of penetrant is 0.2%, the solid-liquid ratio is 1:4, the temperature is 130°C, the soaking time is 30min; three-stage refining, the concentration is 30%, the disc grinding gap is 1.5mm→0.5mm→0.1mm; , temperature 80°C, time 30min; screening, sieve gap 0.15mm.

[0031] Eucalyptus wood adopts the technological condition of conventional chemical thermomechanical pulping process: get eucalyptus wood chips 2kg (absolutely dry); Normal pressure steaming 15min; Extrusion loosening, compression ratio 4: 1; Chemical impregnation, NaOH c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com