Method for characterizing distribution stability of finished product cut tobacco structure by using conventional chemical compositions

A technology of chemical composition and shredded tobacco structure, which is applied in the field of tobacco processing, can solve problems such as distribution stability errors of shredded tobacco, and achieve the effect of improving cigarette quality and optimizing control

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

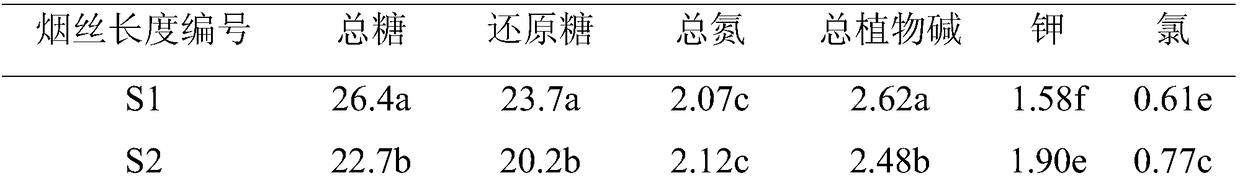

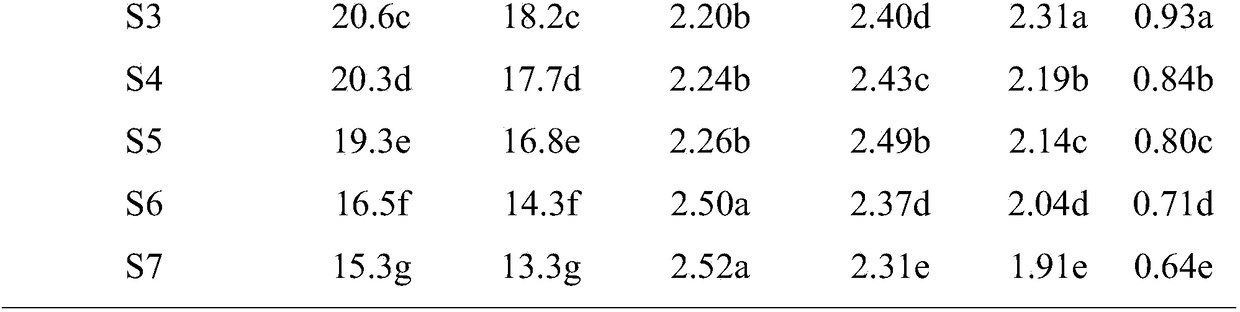

[0040] Example 1: By calculating the stability coefficients of the conventional chemical composition data of several finished cut tobaccos of a certain batch, the stability of the structural distribution of the finished cut tobaccos of the batch can be characterized to a certain extent.

[0041] Sample: Finished shredded tobacco of a certain specification of Yunyan cigarettes.

[0042] (1) Sampling of finished shredded tobacco: select 2 batches of finished shredded tobacco of a certain specification of cigarettes as the test material, take 1 kg of finished shredded tobacco samples at intervals of 30 seconds before wind feeding, and sample 30 times for the 2 batches of finished shredded tobacco respectively;

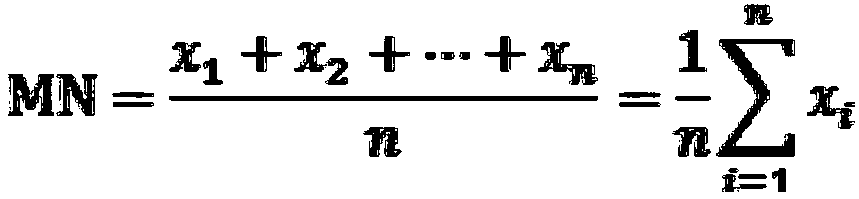

[0043] (2) Determination of conventional chemical components: Determination of conventional chemical components (total sugar, reducing sugar, total nitrogen, total plant alkaloids, potassium and chlorine) of 2 batches of 30 finished tobacco shreds respectively by chemical ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com