Multiphase-doped nickel-cobalt-manganese ternary anode material and preparation method and application thereof

A cathode material, nickel-cobalt-manganese technology, which is applied in the field of complex-phase doped nickel-cobalt-manganese ternary cathode materials and their preparation, can solve the problems of difficulty in taking into account the multi-dimensional improvement of material properties, single technical goals, etc., and achieve improved structural stability. properties, promoting the mass transfer process, and slowing down the effect of stress and strain

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

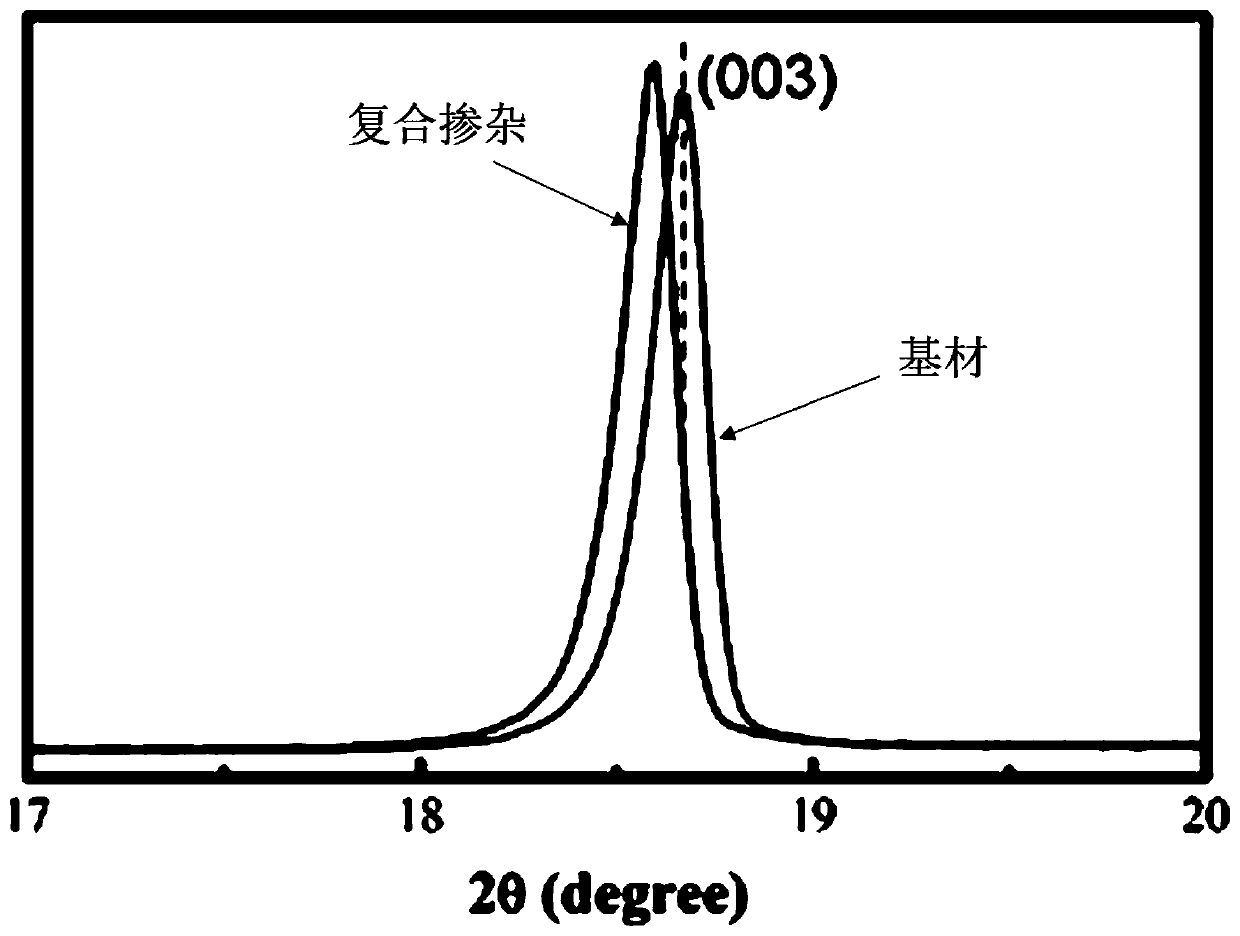

[0037] Example 1 The preparation method of the multi-phase doped nickel-cobalt-manganese ternary positive electrode material is: nickel sulfate, cobalt sulfate, and manganese sulfate are dissolved in deionized water according to the molar ratio of 5:2:3, and sodium hydroxide is used as a precipitating agent. Ammonia water was used as a complexing agent to prepare nickel-cobalt-manganese precursors by co-precipitation method. After the precursor is uniformly mixed with the lithium source and the composite additive composed of boric acid and strontium oxide, it is calcined at 950° C. for 12 hours to obtain the target product. Among them, the lithium source is Li 2 CO 3 , the lithium ratio is 1.08 (that is, the molar ratio Li / Me=1.08, Me is the sum of transition metals Ni, Co, and Mn), the additive boric acid is 0.1% of the total mass of the nickel-cobalt-manganese precursor, and strontium oxide is the nickel-cobalt-manganese precursor 0.1% of the total mass of the body.

[00...

Embodiment 2

[0042] Example 2 The preparation method of the multiphase doped nickel-cobalt-manganese ternary positive electrode material is as follows: nickel nitrate, cobalt nitrate, and manganese nitrate are dissolved in deionized water according to the molar ratio of 55:15:30, and sodium carbonate is used as a precipitating agent, ammonia water As a complexing agent, nickel-cobalt-manganese precursors were prepared by co-precipitation method. After the precursor is uniformly mixed with the lithium source and the composite additive composed of antimony oxide and strontium oxide, it is calcined at 930° C. for 13 hours to obtain the target product. Among them, the lithium source is Li 2 CO 3 , the lithium ratio is 1.1 (that is, the molar ratio Li / Me=1.1, Me is the sum of the transition metals Ni, Co, and Mn), the additive antimony oxide is 0.9% of the total mass of the nickel-cobalt-manganese precursor, and the strontium oxide is nickel-cobalt-manganese 1.3% of the total mass of the prec...

Embodiment 3

[0047] Example 3 The preparation method of the multiphase doped nickel-cobalt-manganese ternary positive electrode material is as follows: nickel nitrate, cobalt nitrate, and manganese nitrate are dissolved in deionized water according to the molar ratio of 6:2:2, and sodium hydroxide is used as a precipitating agent. Ammonia water was used as a complexing agent to prepare nickel-cobalt-manganese precursors by co-precipitation method. After the precursor is uniformly mixed with the lithium source and the composite additive composed of bismuth oxide and neodymium oxide, it is calcined at 920° C. for 15 hours to obtain the target product. Among them, LiOH is selected as the lithium source, the lithium ratio is 1.3 (that is, the molar ratio Li / Me=1.3, and Me is the sum of transition metals Ni, Co, and Mn), and the additive boron oxide is 0.3% of the total mass of the nickel-cobalt-manganese precursor. Zirconia is 0.35% of the total mass of the nickel-cobalt-manganese precursor. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com