Double main element-dynamic kernel principal component analysis fault diagnosis method based on chemical TE process

A dynamic core pivot and fault diagnosis technology, applied in design optimization/simulation, special data processing applications, complex mathematical operations, etc., and can solve problems such as low model accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

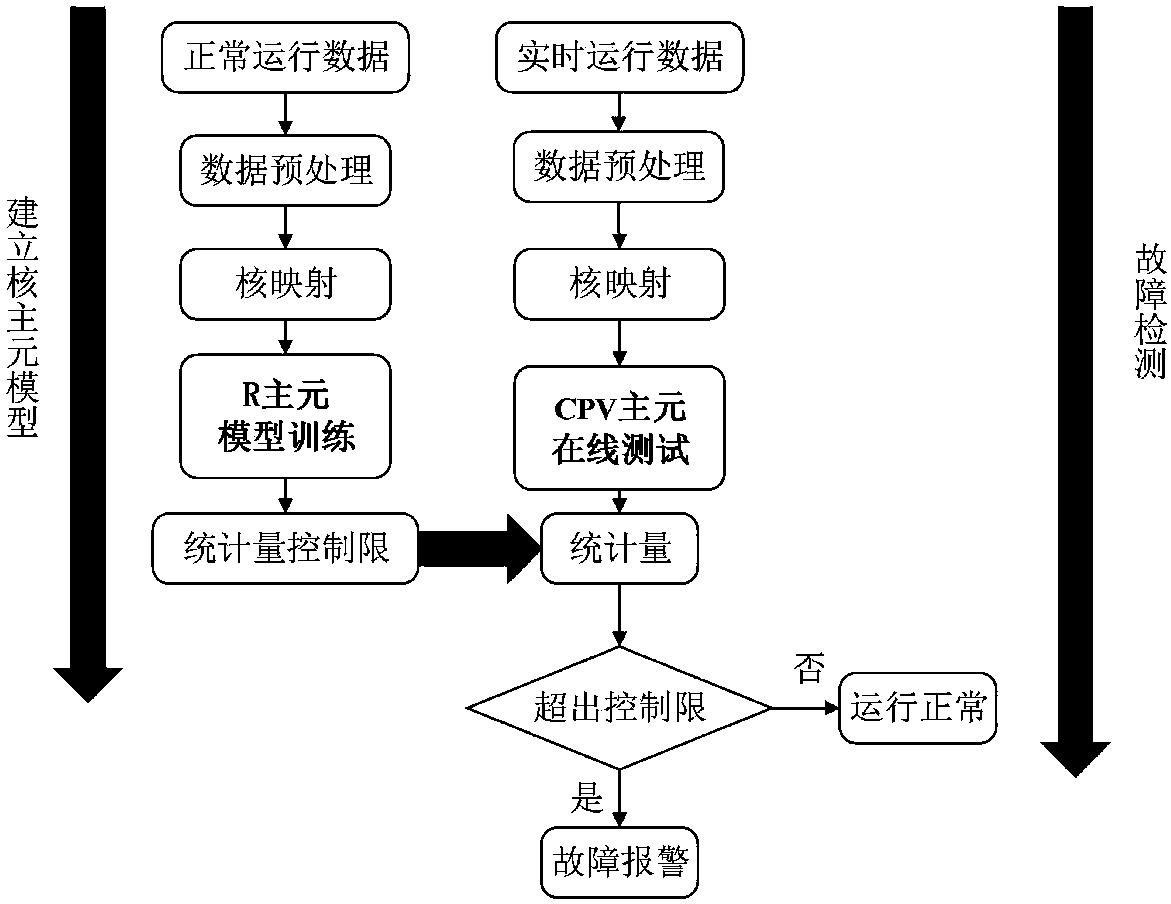

AI Technical Summary

Problems solved by technology

Method used

Image

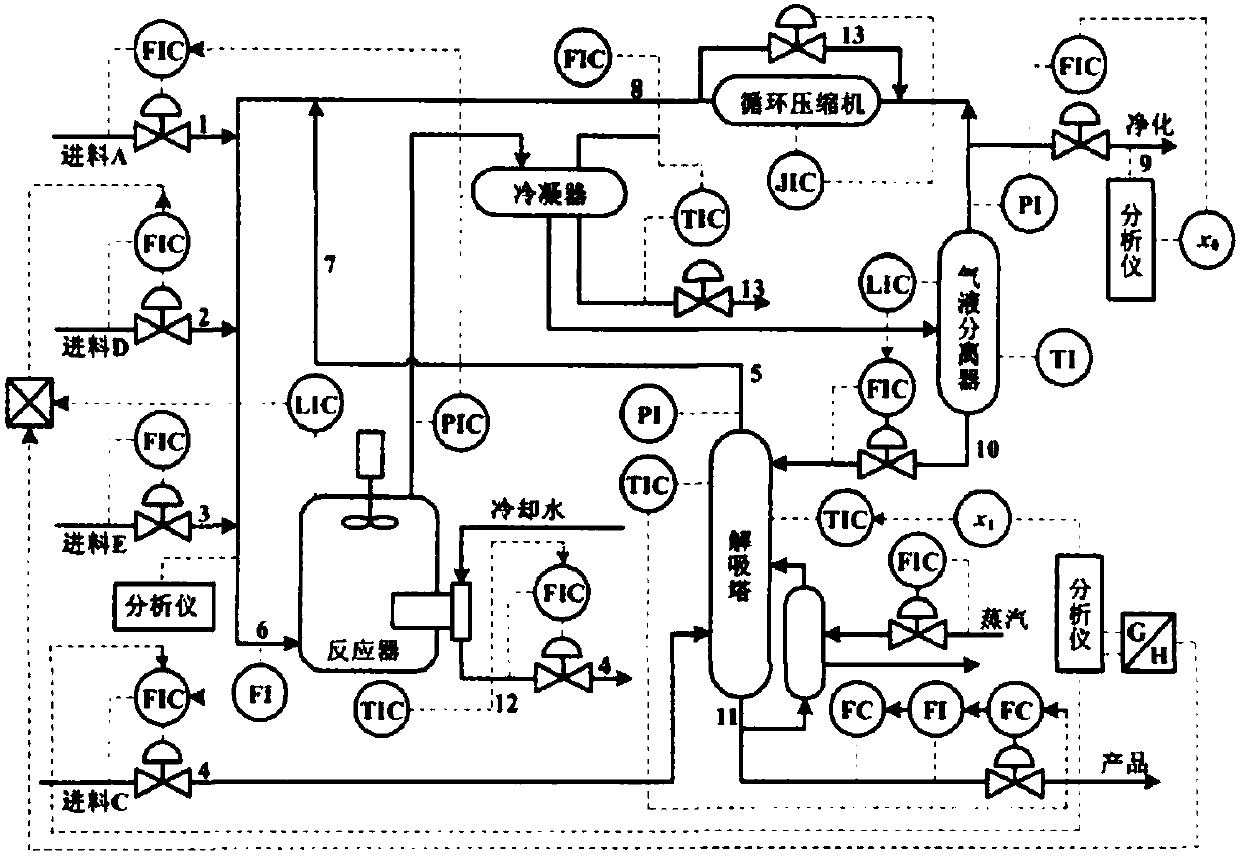

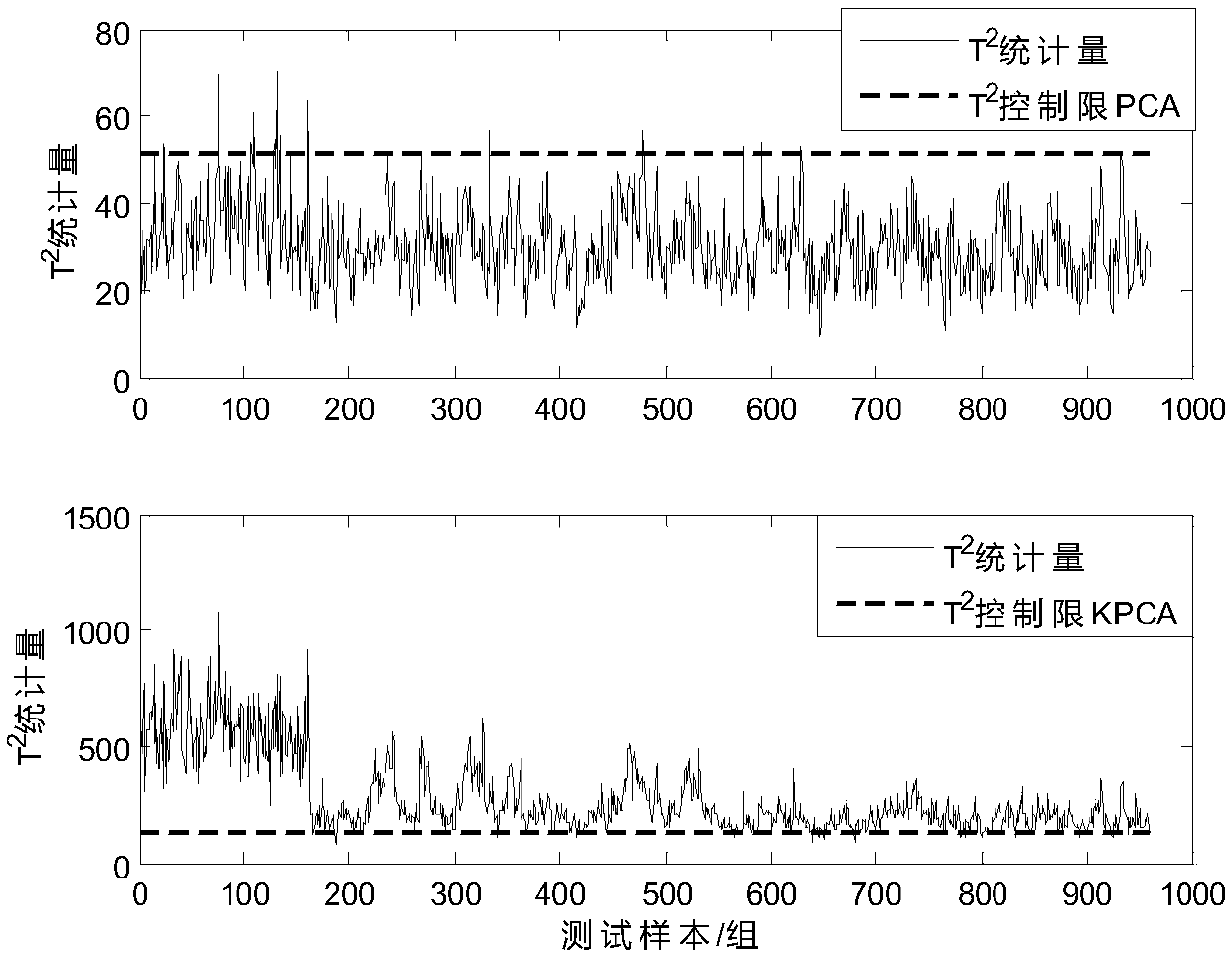

Examples

Embodiment Construction

[0085] 1. Generate a dynamic matrix

[0086] Select normal sample data, calculate the mean and standard deviation, and standardize the sample data to construct a training matrix; determine the optimal order and generate a dynamic matrix;

[0087] For example, firstly, the original data (including training samples 480*52 and test samples 960*52) are standardized, and the processing steps are as follows:

[0088] Suppose the original data x of n×p dimension ij , the matrix of observed values after standardized transformation is

[0089]

[0090] in

[0091]

[0092] After standardized transformation, the mean value of each column of matrix X is 0, and the standard deviation is 1.

[0093] The key to solving the autocorrelation problem of the DKPCA model is to determine the order h of the autoregressive model. Generally, h=1 or 2 is used in engineering applications, and the dynamic characteristic determination algorithm (DOD) is used to analyze the dynamic relationship...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com