High-entropy flux cored wire for aluminum-steel MIG welding and preparation method of high-entropy flux cored wire

A flux-cored welding wire, high-entropy technology, applied in welding equipment, welding medium, welding/cutting medium/material, etc., can solve the problems of reduced strength of welded joints, achieve improved compatibility, good comprehensive mechanical properties, and high strength Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] Specific embodiments of the present invention will be described in detail below.

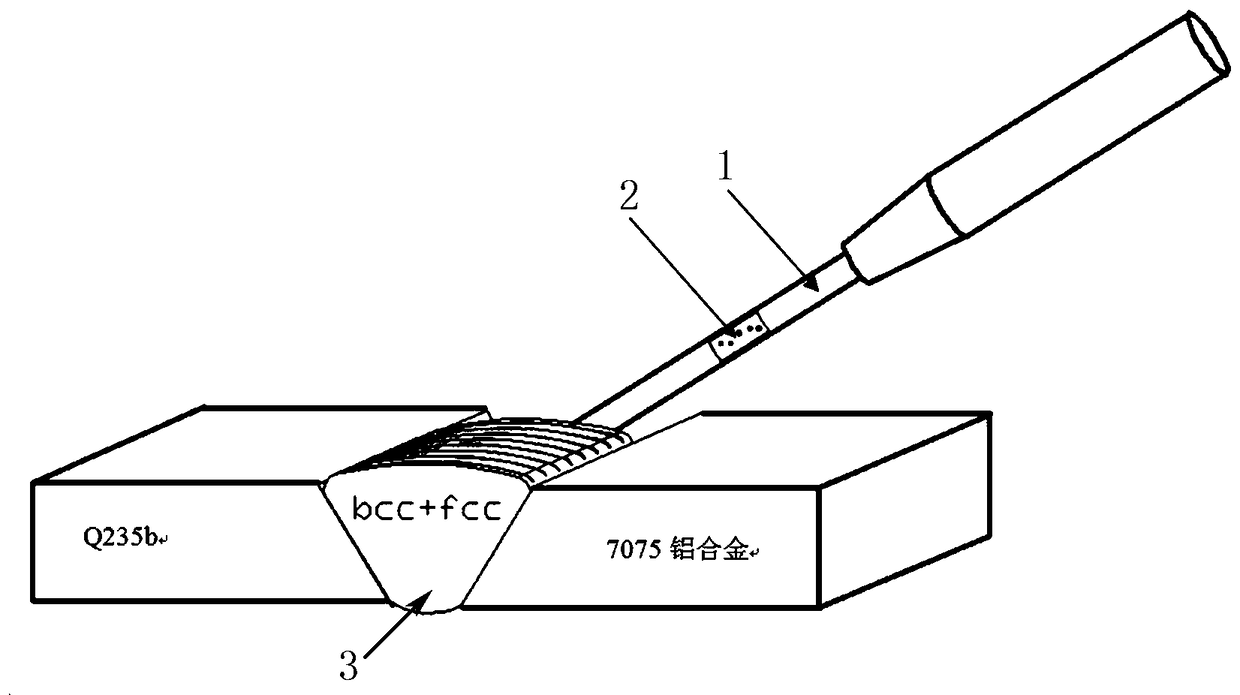

[0025] A high-entropy flux-cored wire for aluminum-steel MIG welding, including a powder and a sheath.

[0026] The powder is composed of the following components by atomic percentage: the total atomic percentage is 100%, of which Fe is 5%~15%, Al is 10%~20%, Co is 20%~30%, and Cr is 18%~35%. , Ni is 20%~35%, and Cu is 5%~13%.

[0027] The sheath material is industrial high-purity copper strip (99.99%) with a width of 10±0.1mm and a thickness of 0.5±0.04mm.

[0028] The preparation method of the above-mentioned high-entropy flux-cored welding wire is implemented according to the following steps:

[0029] Step 1. Melting master alloy

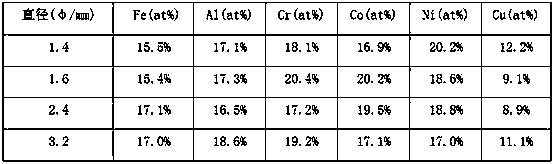

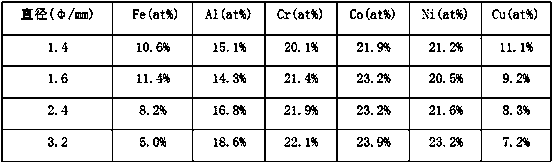

[0030] Composition by atomic percentage (see Table 1), the total atomic percentage is 100%, convert the atomic percentage into mass percentage, weigh various high-purity metals (99.99%) according to the mass percentage; mix the above metal materials in a ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com