Rapid calibration method of line-structured light vision sensor based on space plane restriction

A technology of line structured light and calibration method, applied in the field of online structured light vision measurement system, can solve the problems of limited calibration accuracy, inconvenient operation, and unsuitable for on-site calibration, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0036] The implementation process of the present invention will be described in detail below in conjunction with the accompanying drawings and a specific embodiment.

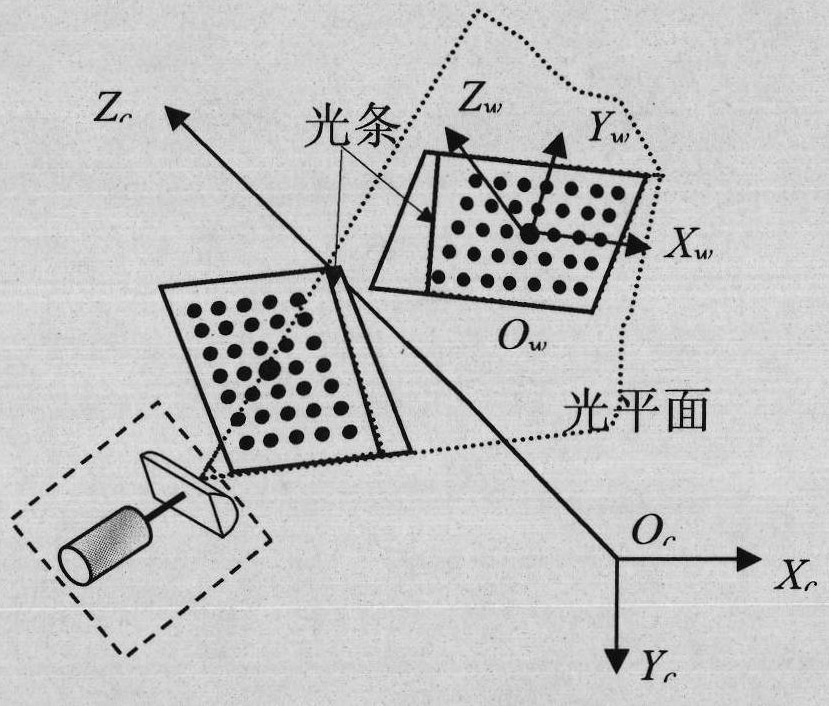

[0037] Such as Figure 4 As shown, the present invention is based on the calibration method of the line structured light visual measurement sensor constrained by the spatial plane, comprising the following steps:

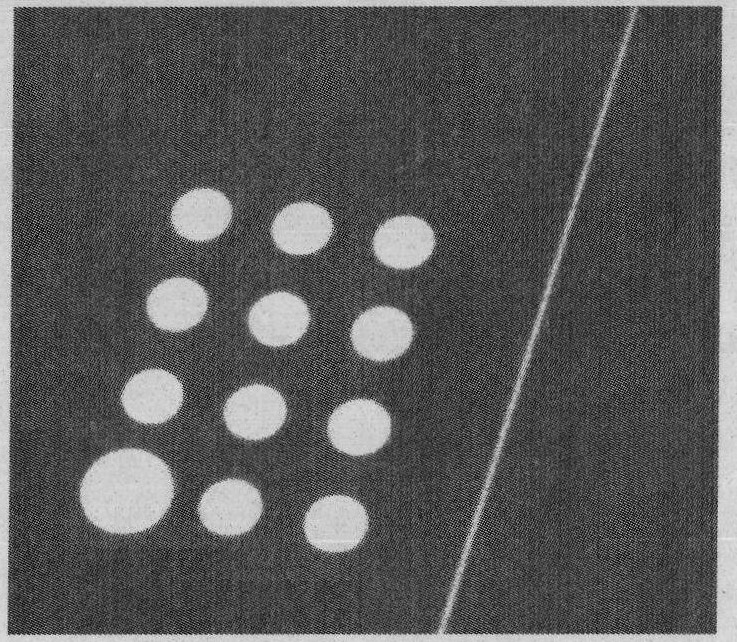

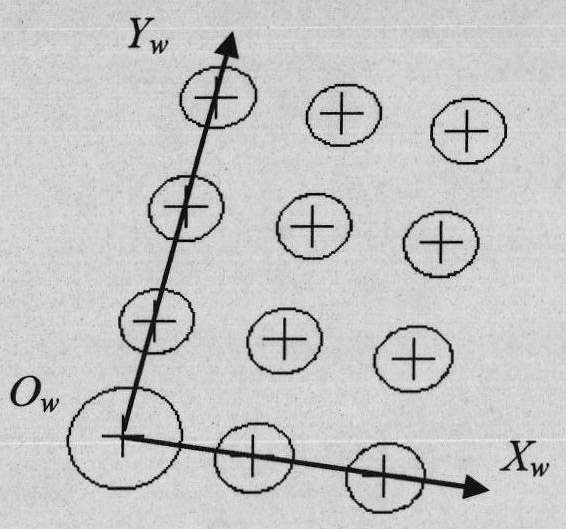

[0038] First, the acquired image of the designed two-dimensional planar target is as follows: Picture 1-1 and Figure 1-2 As shown, there are white feature circles arranged in a matrix on the target plane, the distance D between the centers of adjacent feature circles is selected as 10 mm, the spacing accuracy is (0.01 mm), and the number m of feature circles is 12 to 35. In this embodiment, m= 12. The determination of the values of m and D is mainly determined according to the size of the field of view of the specific camera and the range of the depth of field. The specific determination of the v...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com