High strength multi-component alloy

a multi-component alloy, high-performance technology, applied in the field of multi-component alloys, can solve the problems of limiting the freedom of formulation for alloys and their applications, limiting the application range, and reducing the strength of this type of alloys

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

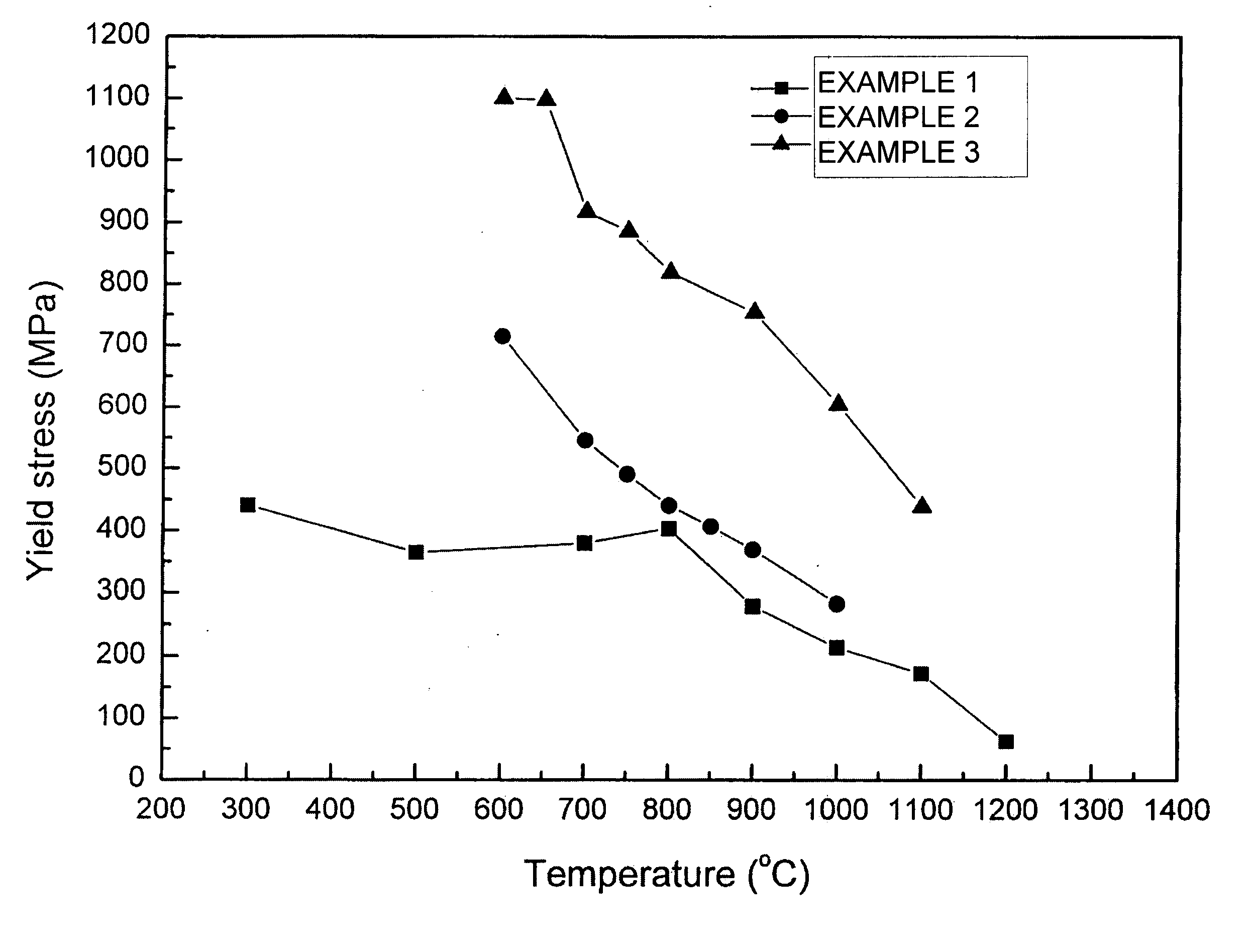

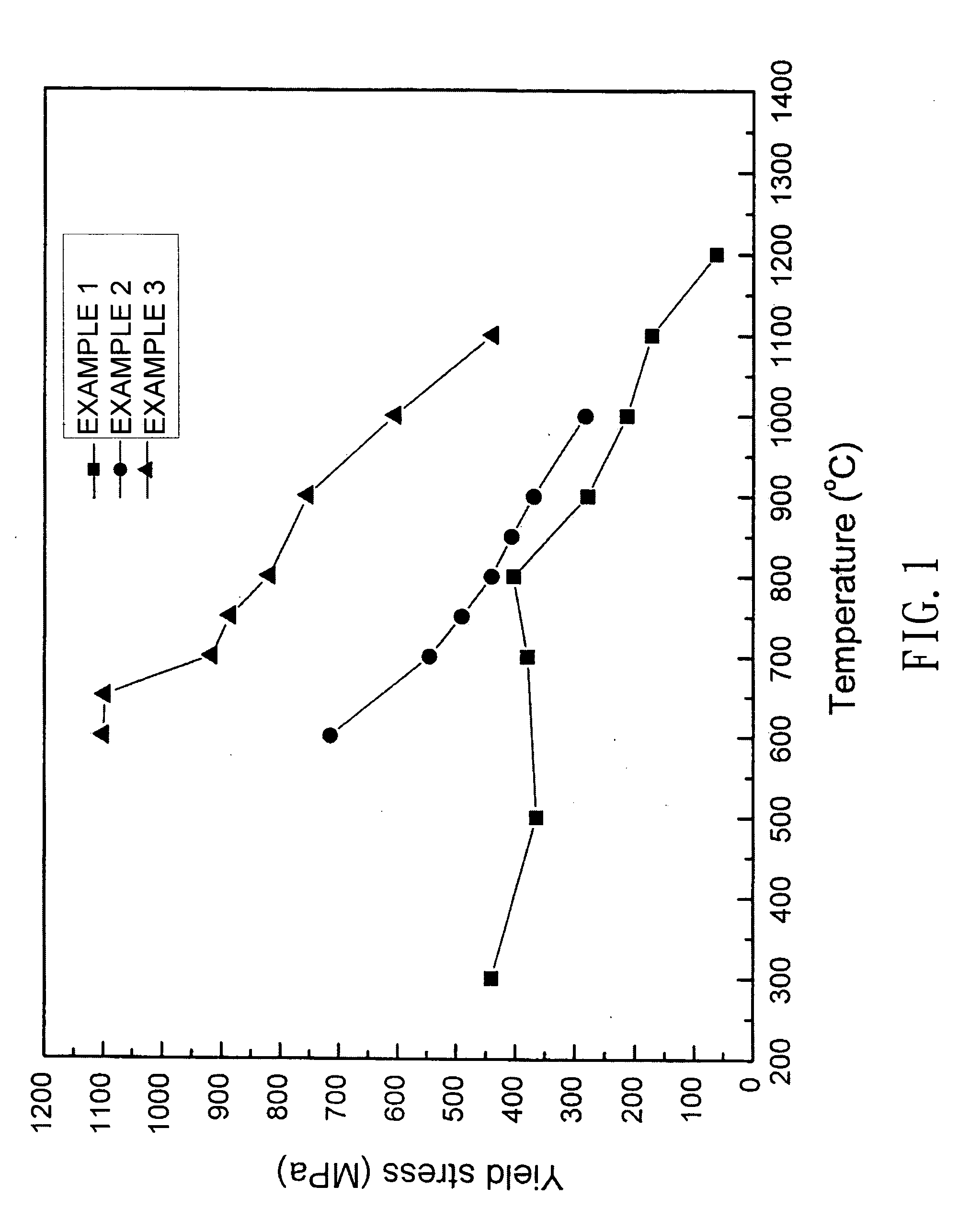

18.2 18.2 18.2 18.2 18.2 9 Example 2 16.7 16.7 16.7 16.7 16.7 16.5 Example 3 14.3 14.3 14.3 14.3 14.3 28.5

[0014] In the example 1, the multi-component alloy contains 18.2 atom % Fe, 18.2 atom % Co, 18.2 atom % Ni, 18.2 atom % Cr, 18.2 atom % Cu and 9 atom % Al.

[0015] In the example 2, the multi-component alloy contains 16.7 atom % Fe, 16.7 atom % Co, 16.7 atom % Ni, 16.7 atom % Cr, 16.7 atom % Cu and 16.5 atom % Al.

[0016] In the example 3, the multi-component alloy contains 14.3 atom % Fe, 14.3atom % Co, 14.3 atom % Ni, 14.3 atom % Cr, 14.3 atom % Cu and 28.5atom % Al.

[0017] About 2000 g of raw material is formulated according to the compositions shown in Table 1 and melted in a vacuum induction furnace. Then, the melt is poured in a copper mold and solidified to form a cast bulk. The cast ingot is cut and machined to produce a plurality of cylindrical rod of 10 mm in diameter, 15 mm in height.

[0018] Vicker's hardness values for the alloy rod samples are measured by using Matsuzawa ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Fraction | aaaaa | aaaaa |

| Fraction | aaaaa | aaaaa |

| Fraction | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com