Online updating method of principal component analysis monitoring model

A monitoring model and principal component analysis technology, which is applied in adaptive control, general control system, control/regulation system, etc., can solve the problems of increased number of monitoring model principal components, unusable, and invalid statistics.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] The present invention will be described in detail below in conjunction with the accompanying drawings and embodiments.

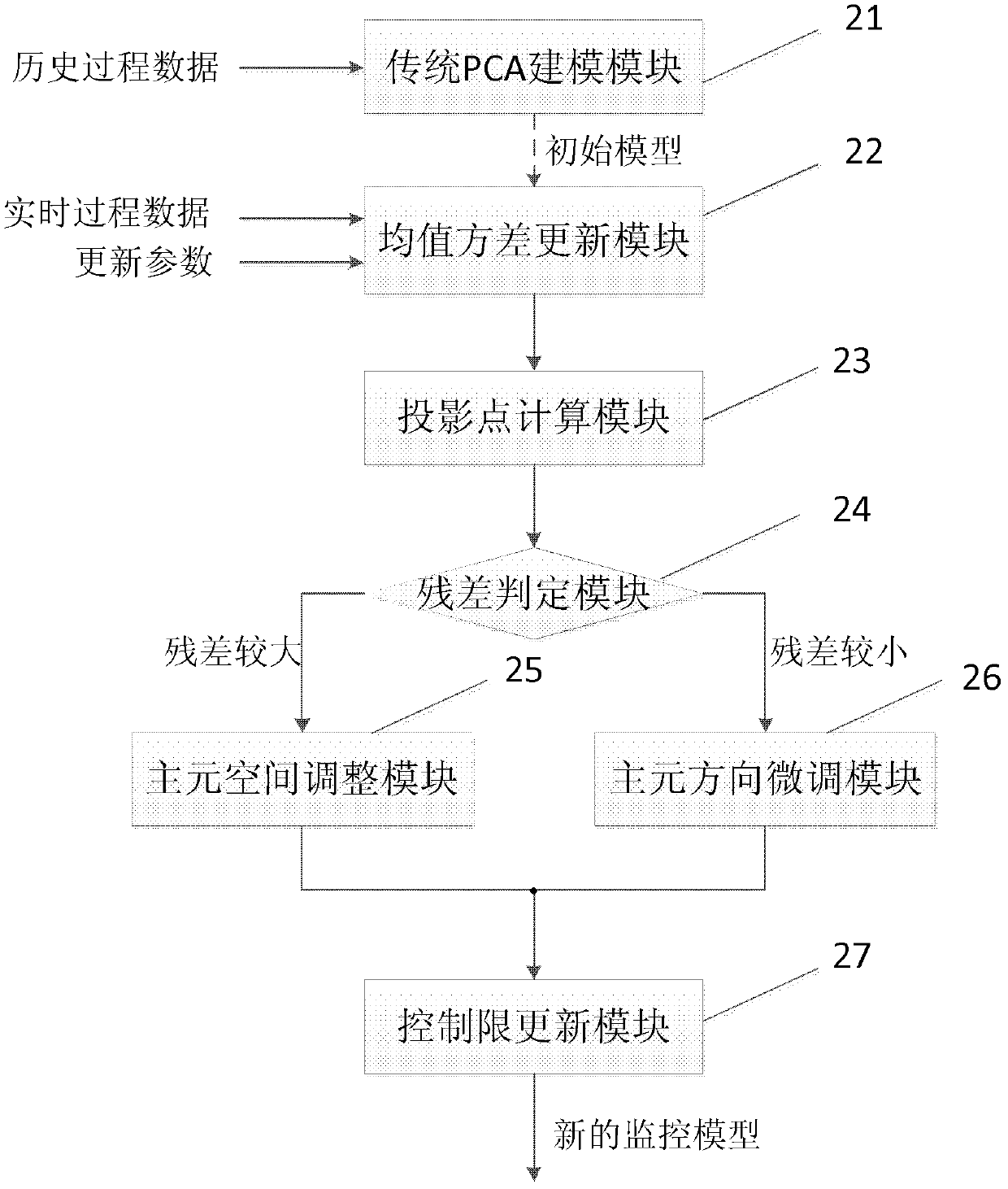

[0035] The present invention is based on the following idea: in a normal operating industrial system, the physical correlation between process variables will not change with time, therefore, the nature of the correlation between variables will not change, and the number of pivots should remain unchanged . The present invention updates the mean value and standard deviation of the model in real time, and adjusts the projection direction of the principal component of the model. Only by using the basic principal component information of the PCA model, the monitoring system can be quickly and effectively updated, thereby implementing industrial systems. At the same time of online monitoring, the function of online updating of PCA model based on real-time process data is realized.

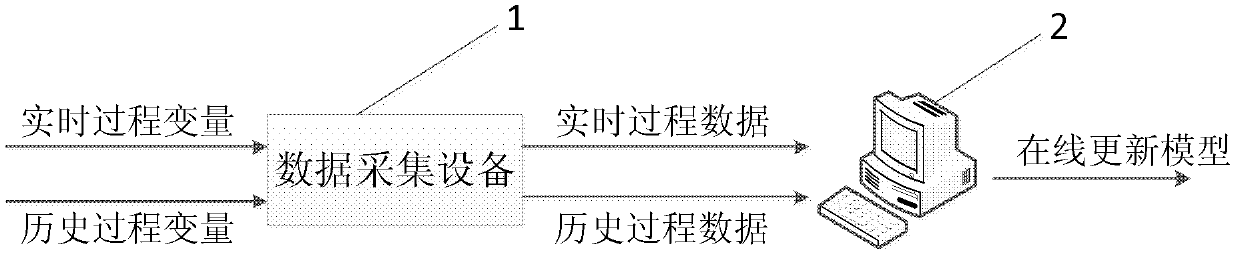

[0036] The inventive method can be summarized as: figure 1 As shown, acco...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com