A quantitative feeding device and a feeding machine using the quantitative feeding device

A bait feeder and feeding hopper technology, which is applied in application, fish farming, climate change adaptation, etc., can solve the problems of troublesome operation, blocked dosing holes, and small adjustable range of feeding amount of bait, so as to improve the utilization rate. , the effect of reducing the impact and reducing the labor intensity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

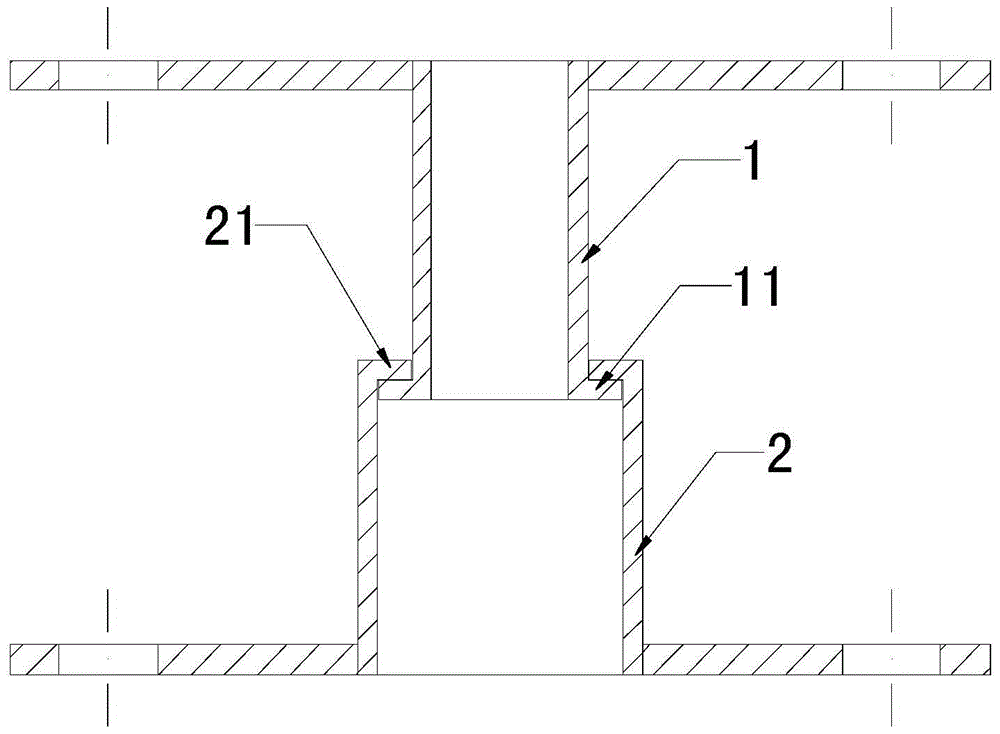

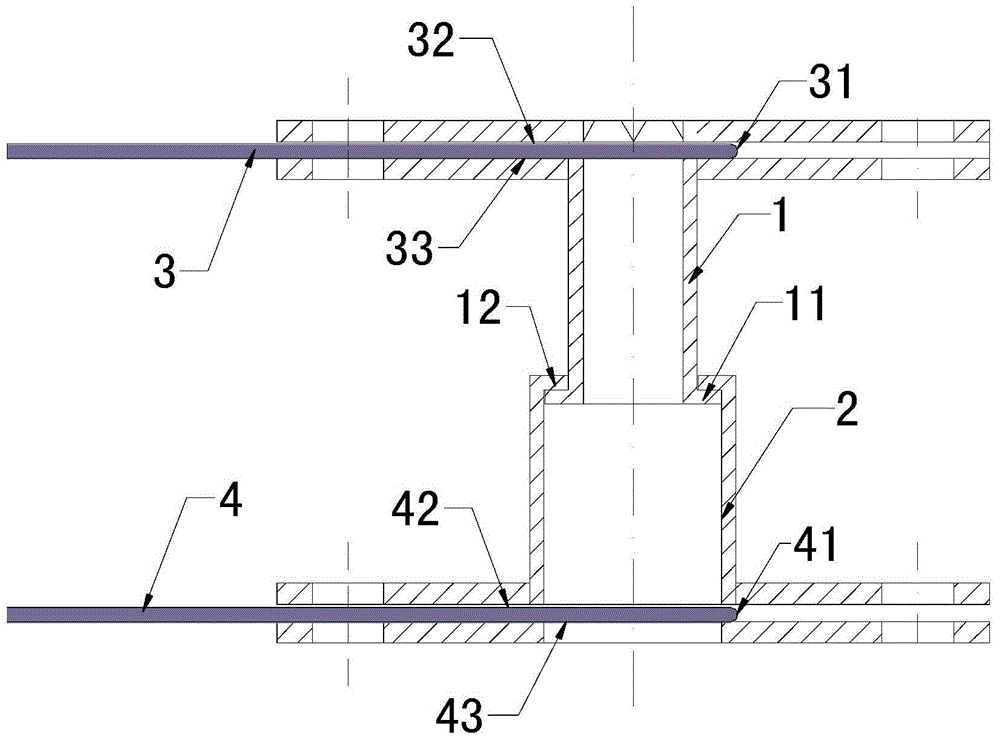

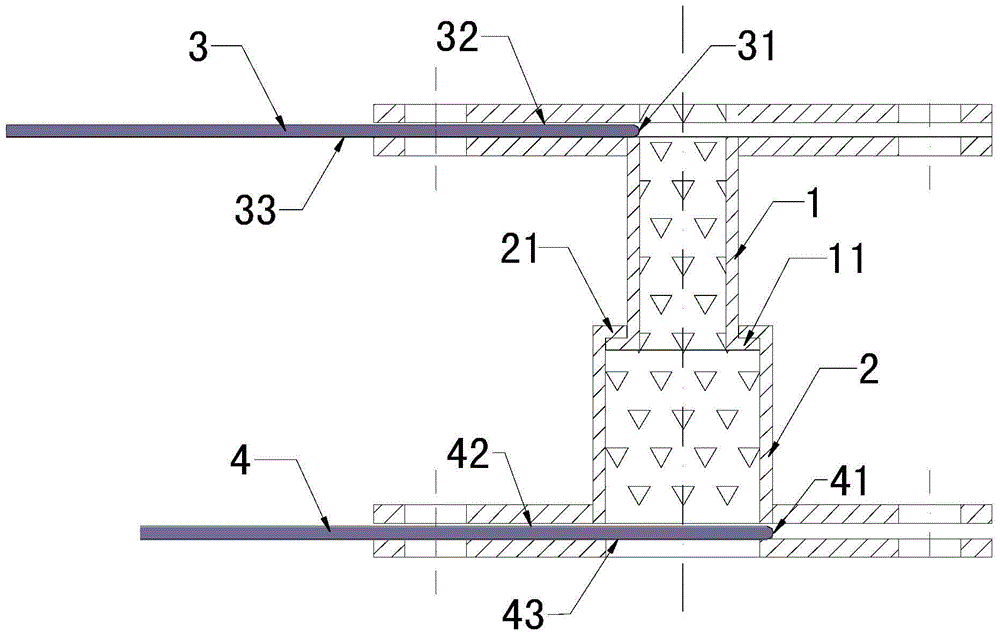

[0029] Example: such as figure 1 , Figure 2(a)-Figure 2(d) As shown, a quantitative feeding device includes a first barrel 1, a second barrel 2, a first control door 3 and a second control door 4; both the first barrel 1 and the second barrel 2 are open up and down The cylindrical structure, the first barrel 1 and the second barrel 2 are coaxially arranged; the outer diameter of the first barrel 1 is smaller than the inner diameter of the second barrel 2, and the height of the first barrel 1 is greater than that of the second barrel 2 height; the lower part of the first barrel 1 extends into the second barrel 2 and can move up and down relative to the second barrel 2; Edge 11, the lower end surface of the first flange 11 is flush with the lower end surface of the first material cylinder 1, and the outer surface of the first flange 11 is attached to the inner surface of the second material cylinder 2; the upper part of the second material cylinder 2 The inner side extends in...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com