Shaving cutter profile modifying method based on involute key point

A key point, the technology of shaving knives, which is applied to the knives used for lathes, knives used for planer/slotting machines, accessories of tool holders, etc., can solve the waste of time and resources, multiple grinding, grinding parameter table Correctness and other issues to achieve the effect of reducing the waste of time and resources, saving grinding time, and increasing the efficiency of shaping

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The present invention is described in further detail below in conjunction with accompanying drawing:

[0025] The present invention provides a kind of gear shaving cutter modification method based on the involute key point, and its specific process is:

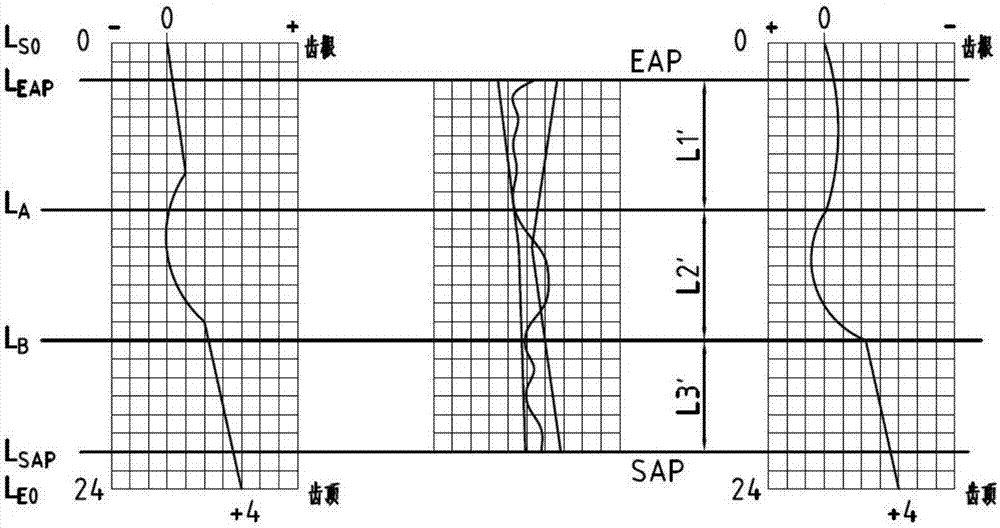

[0026] Step 1. Determine the key points in the tooth profile of the gear in the shaving cutter to be modified. There are at least 3 key points, and the expanded length of each key point, the inclination angle of the tooth profile and the drum shape between adjacent key points are obtained. quantity.

[0027] Step 2, calculate the ordinate of each key point of the gear shaving cutter to be modified; the ordinate of the starting key point of the gear shaving cutter to be modified is: Where ga is the theoretical meshing line length, β b0 is the helix angle of the base circle of the shaving cutter, β b1 is the base circle helix angle of the gear, Mn is the gear modulus, L 1 is the developed length at the end point of t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com