Shaping process method of straight-through frame longitudinal beam plate positioning profiling shear

A process method and a technology of longitudinal beams, which are applied in the field of trimming technology of straight-through vehicle frame longitudinal beam sheet positioning profiling shears, can solve the problems of large space occupation and unfavorable site layout requirements, etc., to improve efficiency and improve process shearing The cutting quality and the effect of uniform height difference between the upper and lower wings

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

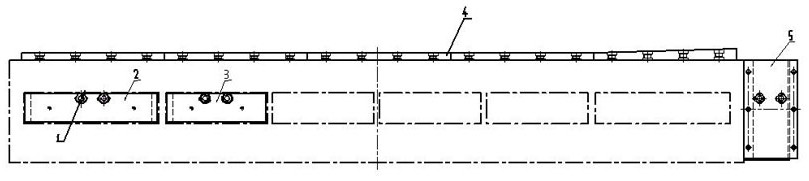

[0016] The invention discloses a method for positioning and trimming the straight-through vehicle frame longitudinal beam sheet material by means of bolts. After the straight-through vehicle frame longitudinal beam sheet material is punched, the stacked sheet material is hung on the material platform of the profiling shear bed. Then push the sheet material to the cutting edge position of the shearing machine according to the slideway of the material rack, respectively align the modification process holes of the front and rear parts of the sheet material with the positioning process holes of the table top of the shearing machine, insert and fix it with the pin, and copy the trimming sheet One side of the material; drag away from the scissors mouth to the pneumatic flip position, flip the piece, and then push the piece to the cutting edge of the shearing machine, repeat the above action to achieve the other side of the profiling shear. The technological method of modifying and lo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com