A grinding wheel modification method and device for a screw

A grinding wheel and screw technology, which is applied in the direction of abrasive surface adjustment devices, grinding machine parts, metal processing equipment, etc., can solve the problems of complex shape modification and low efficiency, and achieve the effect of high modification efficiency and fast modification process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

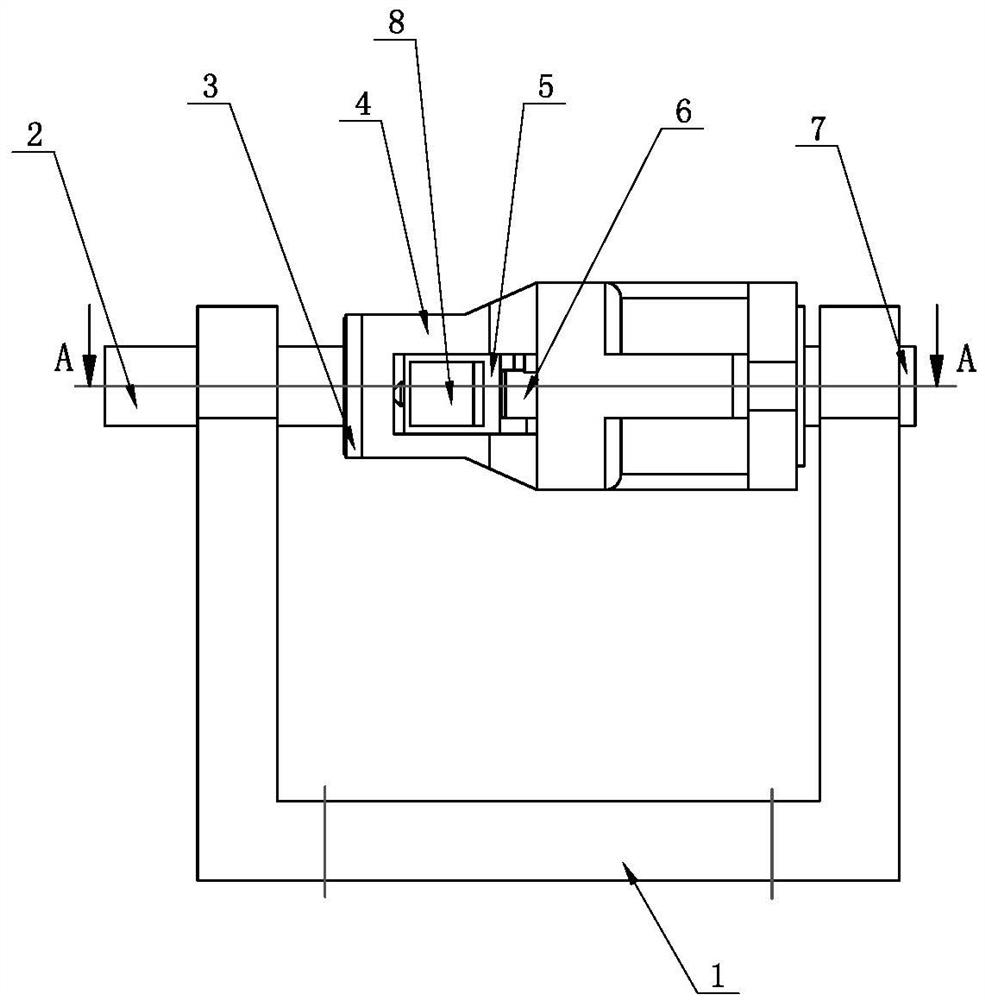

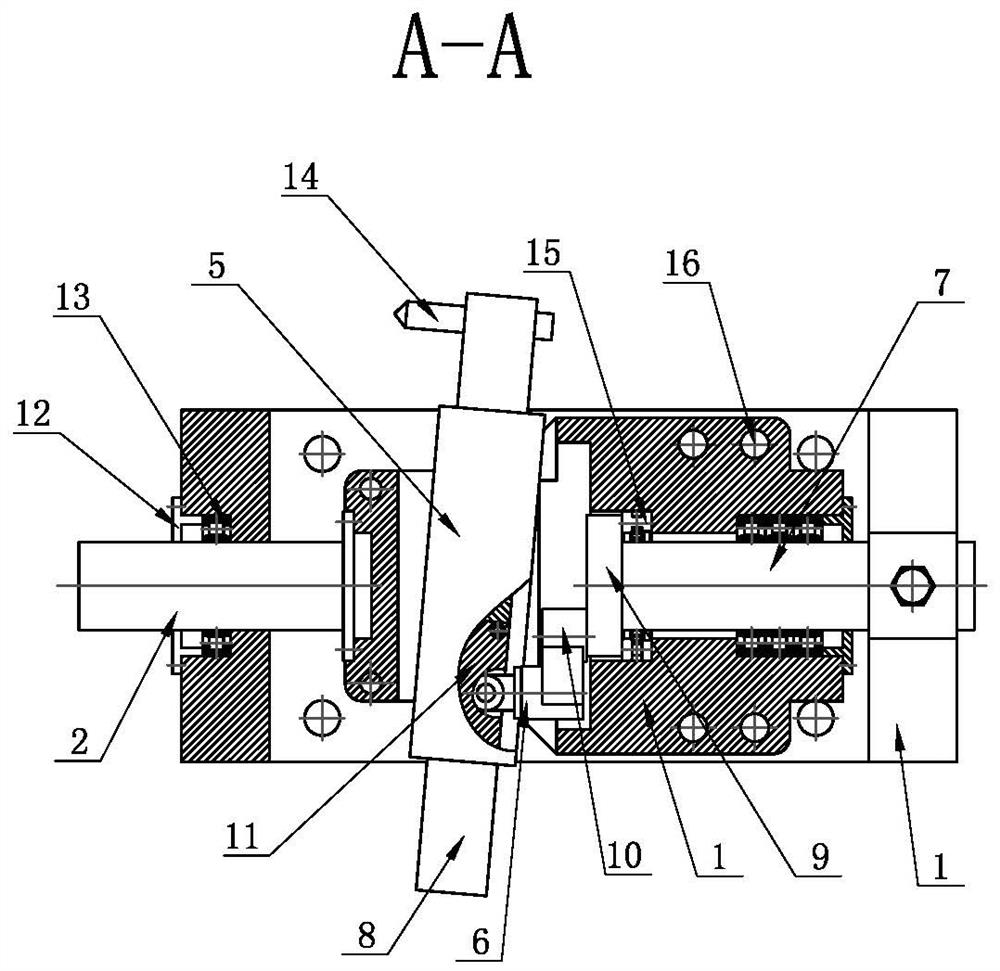

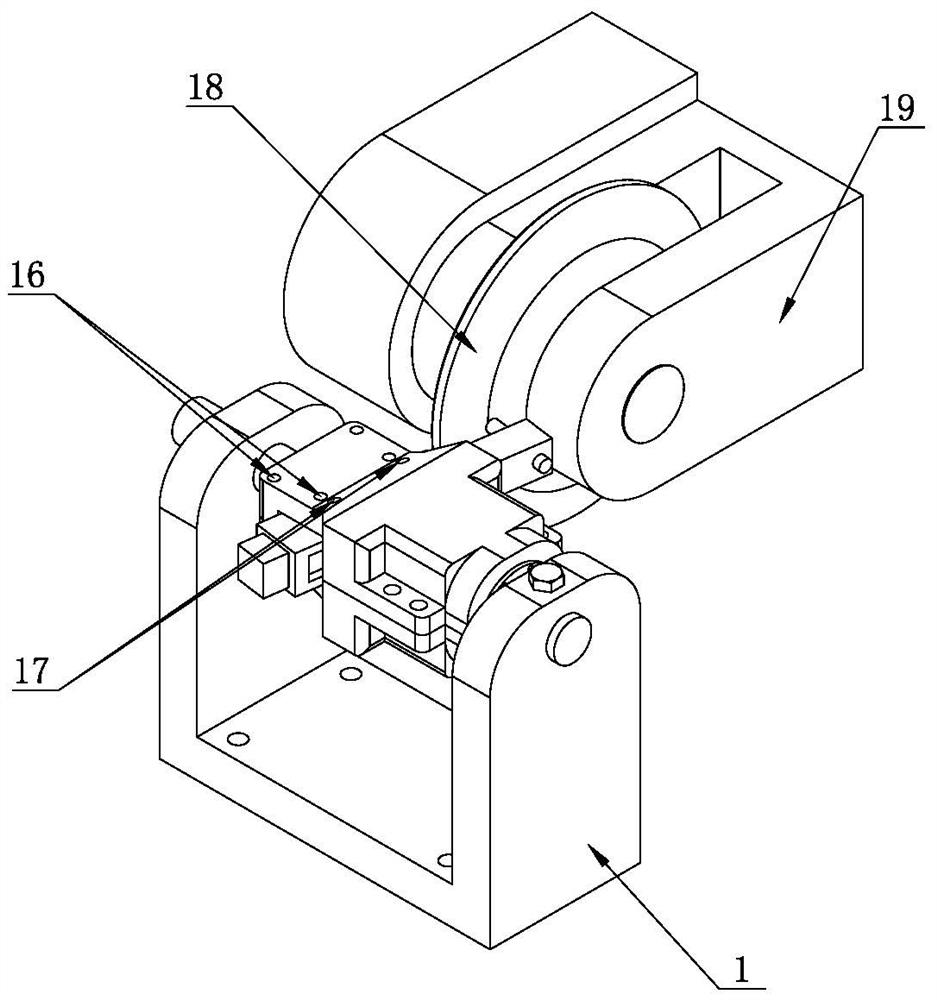

[0021] The present invention will be further described below in conjunction with accompanying drawing.

[0022] A grinding wheel modification method for a screw, comprising the following steps:

[0023] (1) Install the shaping head 14 on the handle 8, the handle 8 is installed in the rotatable rotating outer body 5, and the handle 8 can be telescopically moved in the rotating outer body 5;

[0024] (2) According to the angle of the linear profile of the screw, adjust the angle of the rotating outer body 5 relative to the housing, and after the angle adjustment is completed, fix the rotating outer body 5 on the housing;

[0025] (3) Install the shaping device on the machine table, and connect the rotating shaft 2 that drives the housing to rotate with the rotating disk on the machine tool;

[0026] (4) Adjust the trimming head 14 to the longest elongation position, and align the telescopic movement direction of the gold trimming head with the rotation center of the grinding wh...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com