Safety roller for spinning machine drafting mechanism

A safe spinning machine technology, applied in the direction of spinning machines, drafting equipment, textiles and papermaking, etc., can solve the problems of long service life, reduce the number of repairing times, etc., achieve long service life, reduce the number of repairing times, The effect of convenient and quick loading and unloading

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

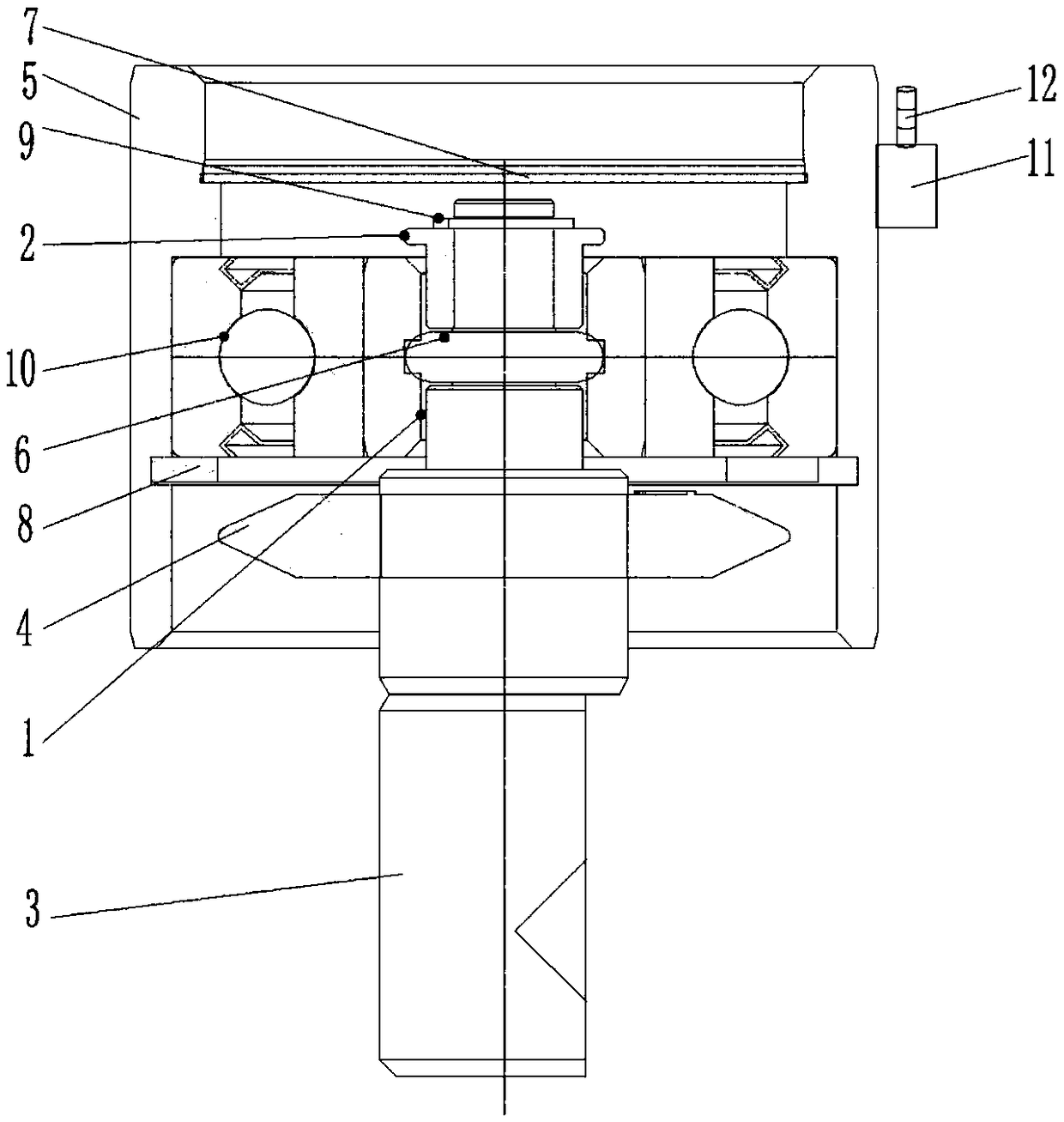

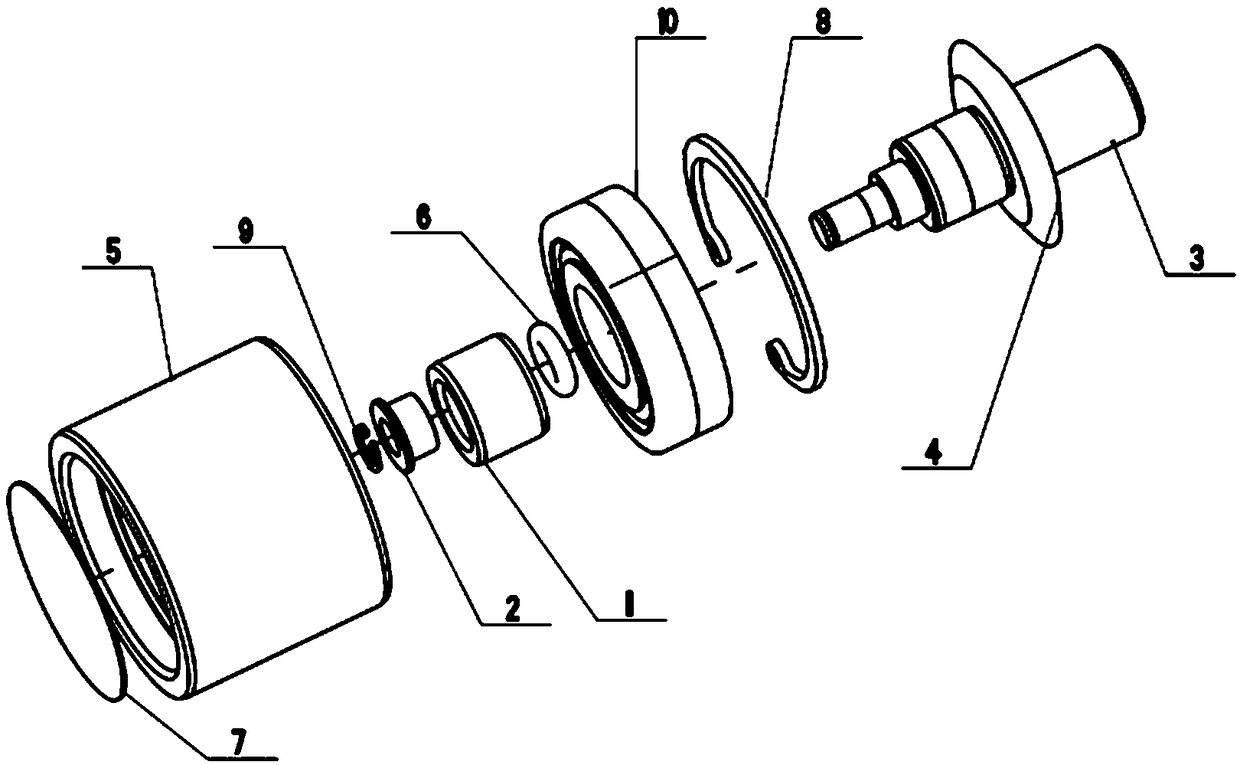

[0028] Such as Figure 1-Figure 2 As shown, a safety top roller used in the drafting mechanism of the spinning machine in this embodiment includes a bearing inner sleeve 1, a shaft sleeve 2, a shaft 3, a nylon ring 4, an outer sleeve 5, a rubber ring 6, a dustproof Cover 7, first retaining ring 8, second retaining ring 9, bearing 10, detection mechanism 11 and automatic alarm 12.

[0029] The connection relationship of the above-mentioned components is as follows: the shaft 3 passes through the rubber ring 6 and is sequentially connected with the bearing inner sleeve 1 and the shaft sleeve 2, and the end of the shaft 3 is sleeved with a second retaining ring 9, and the second washer 9 offsets the shaft sleeve 2; the middle part of the shaft 3 is covered with a nylon ring 4, and the lower part of the shaft sleeve 2 is nested inside the bearing inner sleeve 1; the bearing inner sleeve 1 is integrally nested inside the bearing 10, and the The bearing 10 is nested inside the jack...

Embodiment 2

[0035] Such as Figure 1-Figure 2 As shown, a safety top roller used in the drafting mechanism of the spinning machine in this embodiment includes a bearing inner sleeve 1, a shaft sleeve 2, a shaft 3, a nylon ring 4, an outer sleeve 5, a rubber ring 6, a dustproof Cover 7, first retaining ring 8, second retaining ring 9, bearing 10, detection mechanism 11 and automatic alarm 12.

[0036] The connection relationship of the above-mentioned components is as follows: the shaft 3 passes through the rubber ring 6 and is sequentially connected with the bearing inner sleeve 1 and the shaft sleeve 2, and the end of the shaft 3 is sleeved with a second retaining ring 9, and the second washer 9 offsets the shaft sleeve 2; the middle part of the shaft 3 is covered with a nylon ring 4, and the lower part of the shaft sleeve 2 is nested inside the bearing inner sleeve 1; the bearing inner sleeve 1 is integrally nested inside the bearing 10, and the The bearing 10 is nested inside the jack...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com