Grinder for automobile transmission gears

A transmission gear and grinding technology, which is applied in the direction of machine tools, grinding frames, and grinding beds suitable for grinding workpiece planes, can solve problems such as low efficiency, improve grinding efficiency, prevent excessive grinding, The effect of shortening the grinding time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

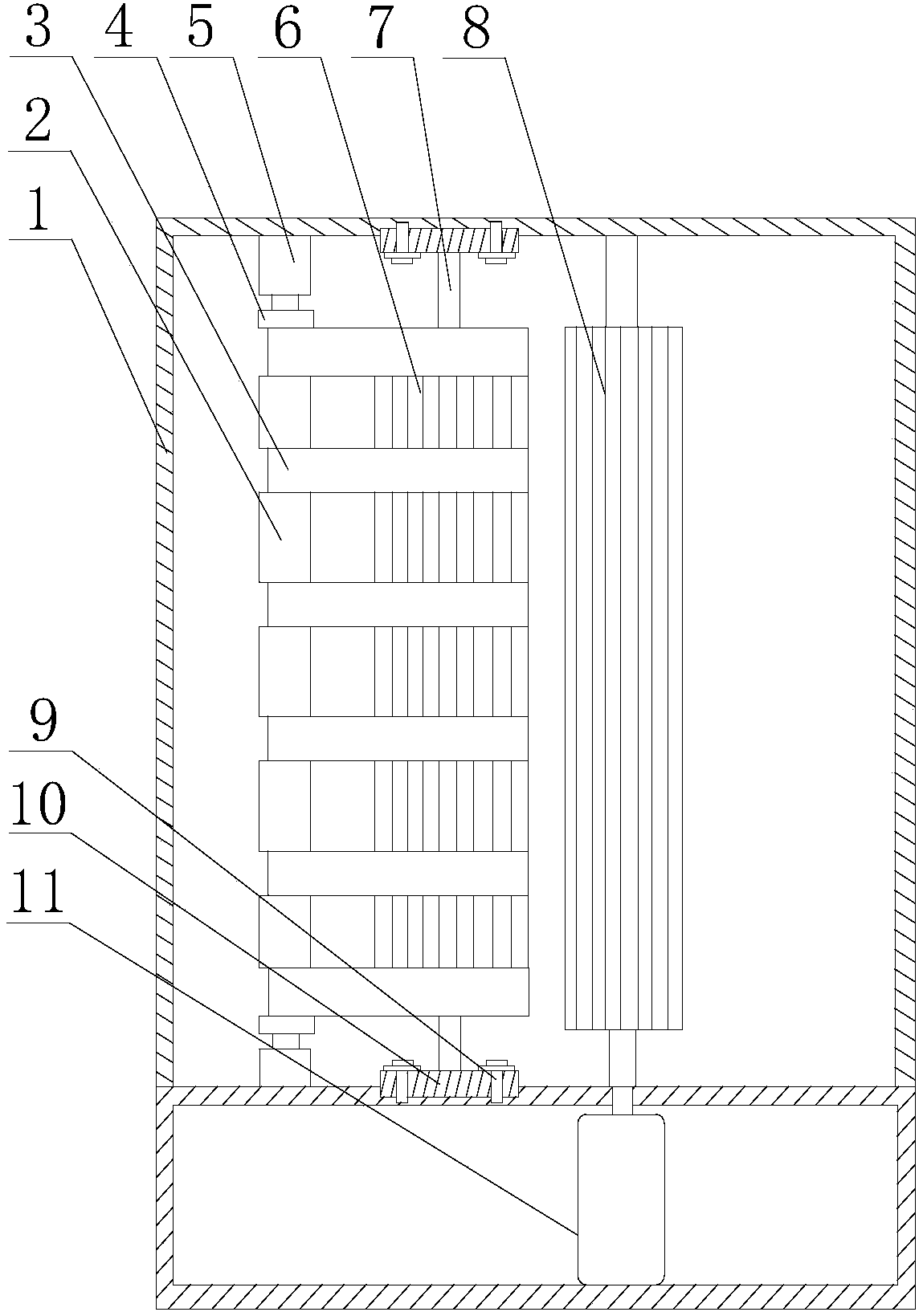

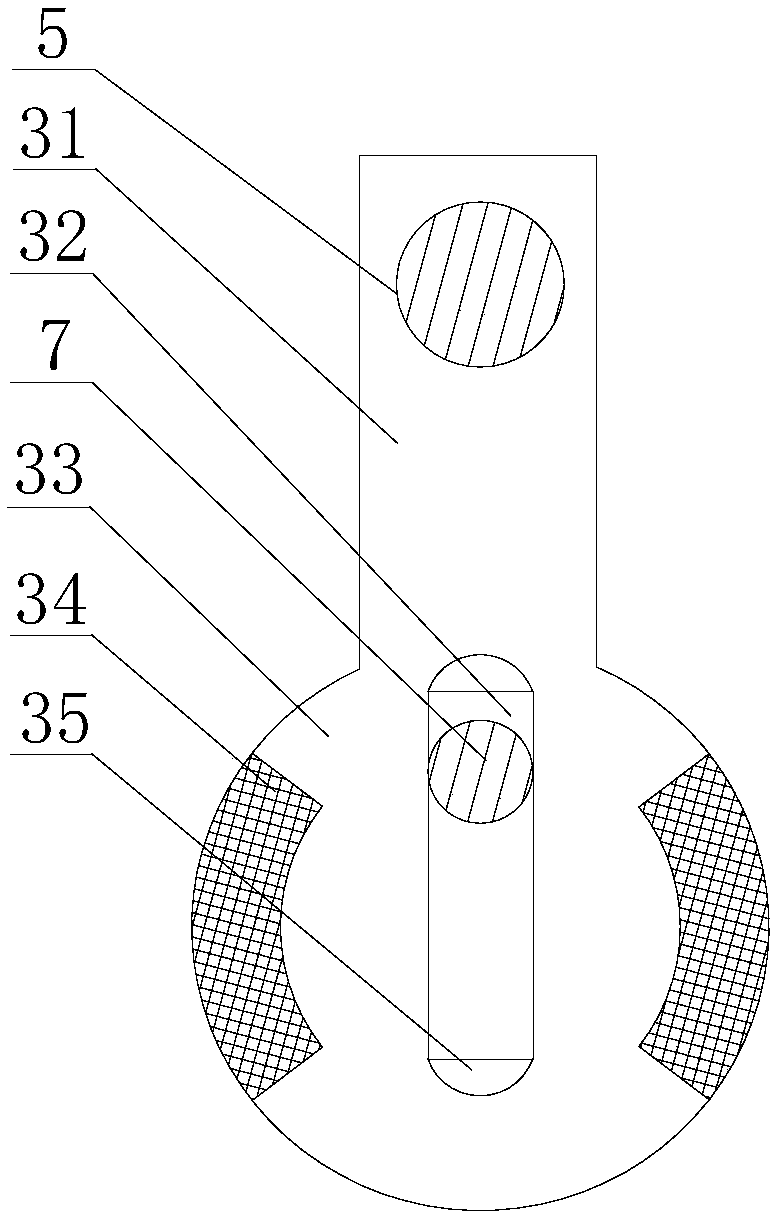

[0019] Such as Figure 1~2 As shown, the present embodiment includes a frame 1, a connecting rod 7, a main grinding head 8, two pressing plates 10 and a motor 11 arranged on one side of the frame 1, and the main grinding head 8 is arranged on the frame 1 through rotation of a rotating shaft. The output end of the motor 11 passes through the side wall of the frame 1 and is connected to the end of the rotating shaft. A central shaft 5 is fixed on the frame 1, and an annular groove is formed on the central shaft 5. A plurality of pads 2 and a plurality of Two side grinding heads 3 are alternately sleeved in the annular groove, threads are provided on the outer walls at both ends of the annular groove, two nuts 4 are sleeved on the annular groove and matched with the threads, the inner walls on both sides of the frame 1 There are a plurality of screw holes distributed side by side. The screw holes are located between the central axis 5 and the rotating shaft and on the same horizo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com