Preparation method and application of high-purity high-fineness graphite powder

A graphite powder, high-purity technology, applied in chemical instruments and methods, inorganic chemistry, non-metallic elements, etc., can solve the problems of complex steps, difficult operation, high cost, etc., achieve the effect of reducing the number of grinding times and simple preparation process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

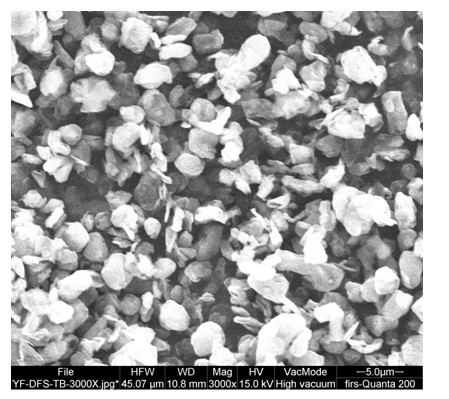

[0031] The preparation method of the high-purity high-fineness graphite powder in the present embodiment specifically comprises the steps:

[0032] a) At room temperature, the graphite raw material was irradiated with gamma rays with a power of 10 KHz for 2 hours;

[0033] b) Use jet mill to pulverize the graphite raw material that has completed step a). Since the bond between carbon and carbon atoms in graphite has been interrupted by gamma rays, the bonding force between carbon and carbon atoms is greatly reduced. Therefore, graphite Raw materials are easily crushed and can be crushed to a smaller particle size than the prior art;

[0034] c) using high-purity water to carry out conventional wet grinding of the graphite raw material that has completed step b);

[0035] d) Pickling the graphite raw material that has completed step c), so as to remove the metal impurities mixed in the graphite powder. The acid solution used can be hydrochloric acid, sulfuric acid or nitric ac...

Embodiment 2

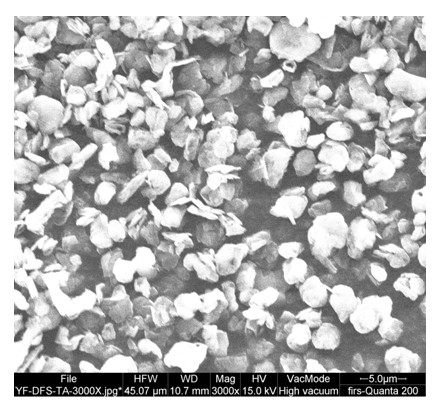

[0045]The preparation method of the high-purity and high-fineness graphite powder in the present embodiment specifically comprises the following steps: the graphite raw material is irradiated with γ-rays with a power of 85 KHz, and the duration is 2 hours. The other steps are the same as in the first embodiment. This will not be repeated here.

[0046] figure 2 Shown is the particle size distribution diagram of the high-purity and high-fineness graphite powder prepared in the present embodiment. As can be seen from the figure, the particle size of the graphite powder prepared by the present invention can reach about 2 microns.

Embodiment 3

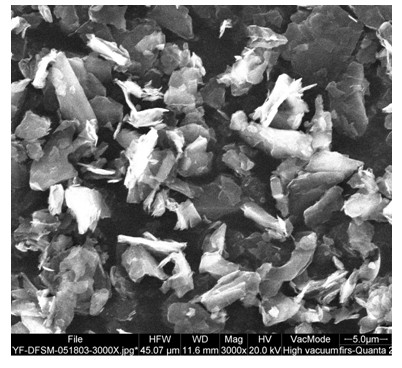

[0048] The preparation method of the high-purity and high-fineness graphite powder in the present embodiment specifically comprises the following steps: the graphite raw material is irradiated with gamma rays with a power of 200 KHz, and the duration is 1 hour. The other steps are the same as in the first embodiment. This will not be repeated here.

[0049] image 3 Shown is the particle size distribution diagram of the high-purity and high-fineness graphite powder prepared in the present embodiment. As can be seen from the figure, the particle size of the graphite powder prepared by the present invention can reach about 2 microns. Compared with Example 1, it can be seen that the longer the time of being irradiated by radiation, the easier the graphite is to be pulverized.

[0050] The step of irradiating the graphite raw material with radiation in the present invention is mainly to break the bond between carbon and carbon atoms in the graphite, so that it can be ground more ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com