Horizontal sand mill

A horizontal sand mill and spindle technology, applied in grain processing and other directions, can solve the problems of large grinding space, limited centrifugal force and high energy consumption, and achieve the effects of reducing energy consumption, improving efficiency and preventing sedimentation at the bottom of the barrel

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

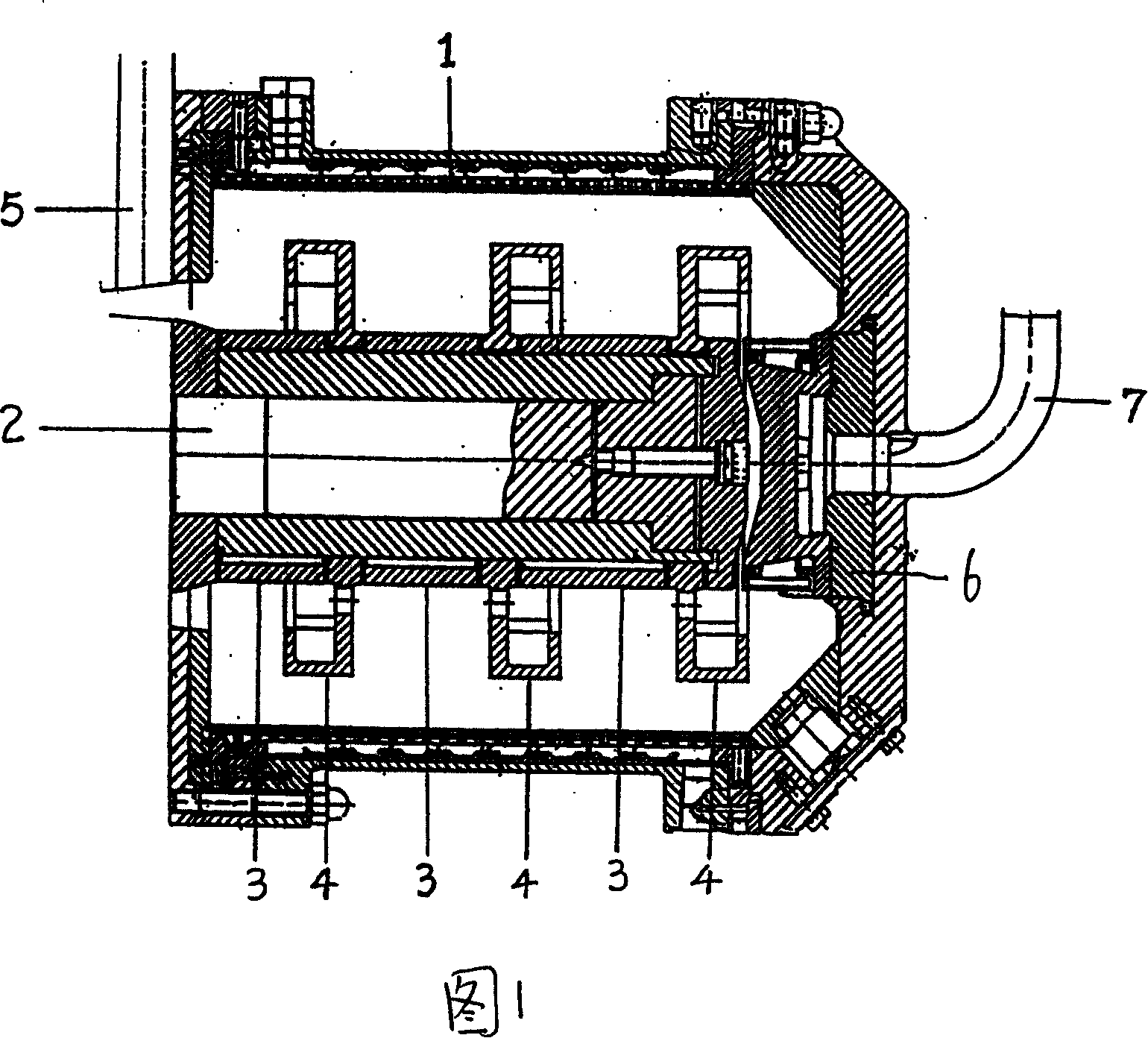

[0012] Embodiment: a horizontal sand mill, comprising a main shaft 2 and a barrel body 1, the main shaft 2 protrudes into the barrel body 1, and several dispersing turbines 4 are installed at intervals on the main shaft protruding into the barrel body.

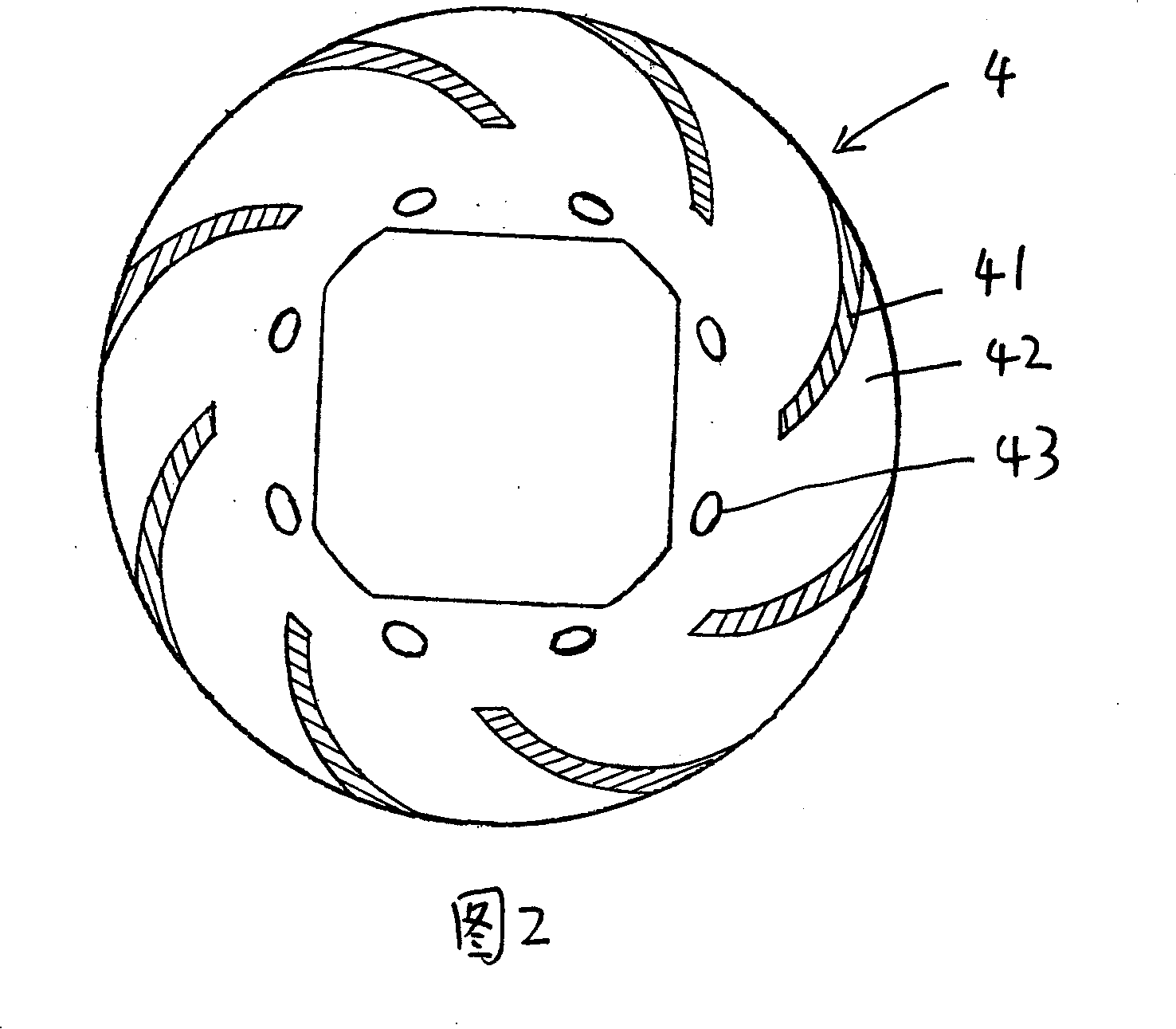

[0013] The casing 3 is fixedly sleeved on the main shaft extending into the barrel. The radial section of the casing is square. The central hole of the dispersing turbine 4 matches the radial section of the casing. Several dispersing turbines are fixedly sleeved on the casing at intervals.

[0014] Several dispersing sheets 41 on the dispersing turbine are distributed centripetally on the dispersing disk 42, and the dispersing sheets 41 are arc-shaped.

[0015] A number of grinding medium return holes 43 are evenly spaced on the dispersing plate 42 at the inner end of the dispersing sheet 41 .

[0016] The working process of the present invention is: the material enters the grinding barrel from the feed pipe 5, and the high-sp...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com