Injection mold

An injection mold and injection molding machine technology, applied in the field of molds, can solve the problems of blockage of vent holes, affecting the normal use of molds, and difficult to control the balance, so as to improve the buffer effect and increase the difficulty of using the mold.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

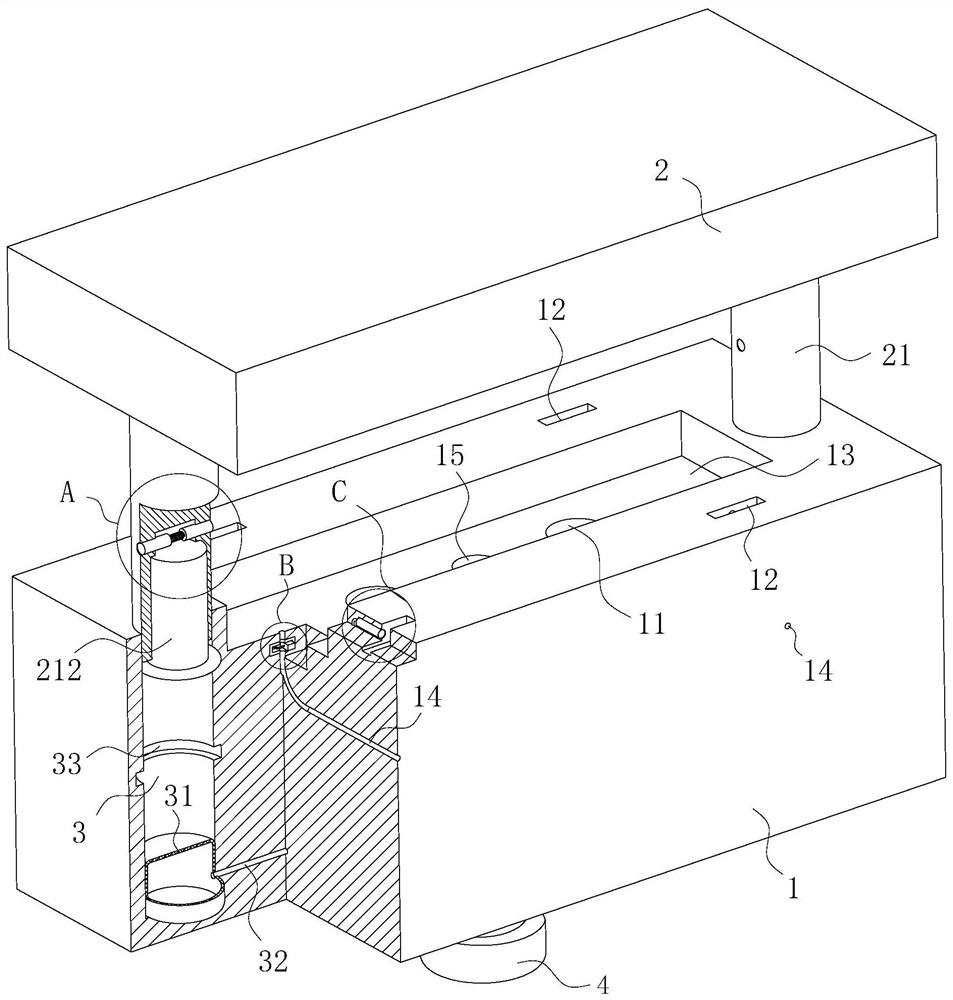

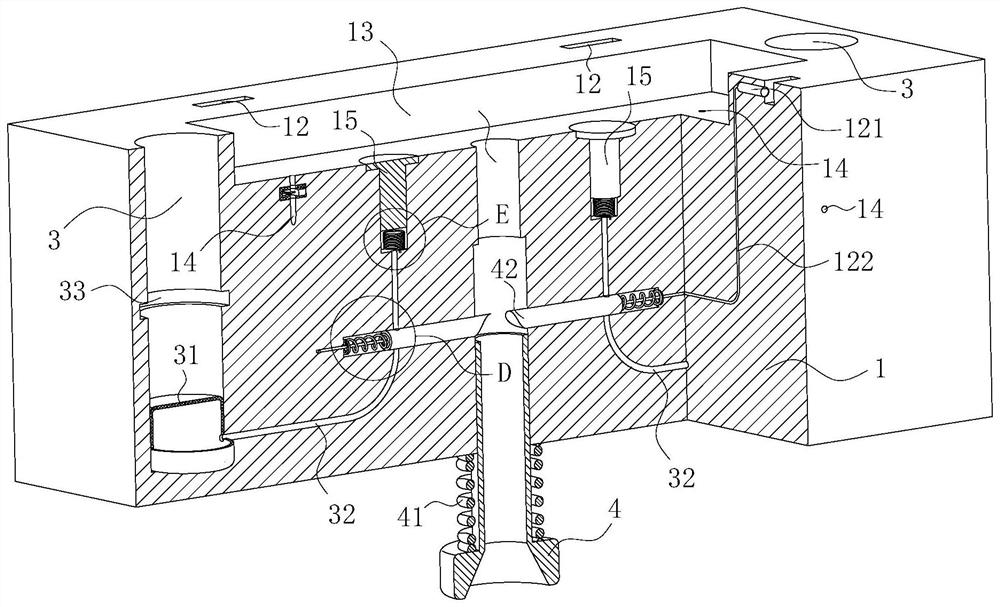

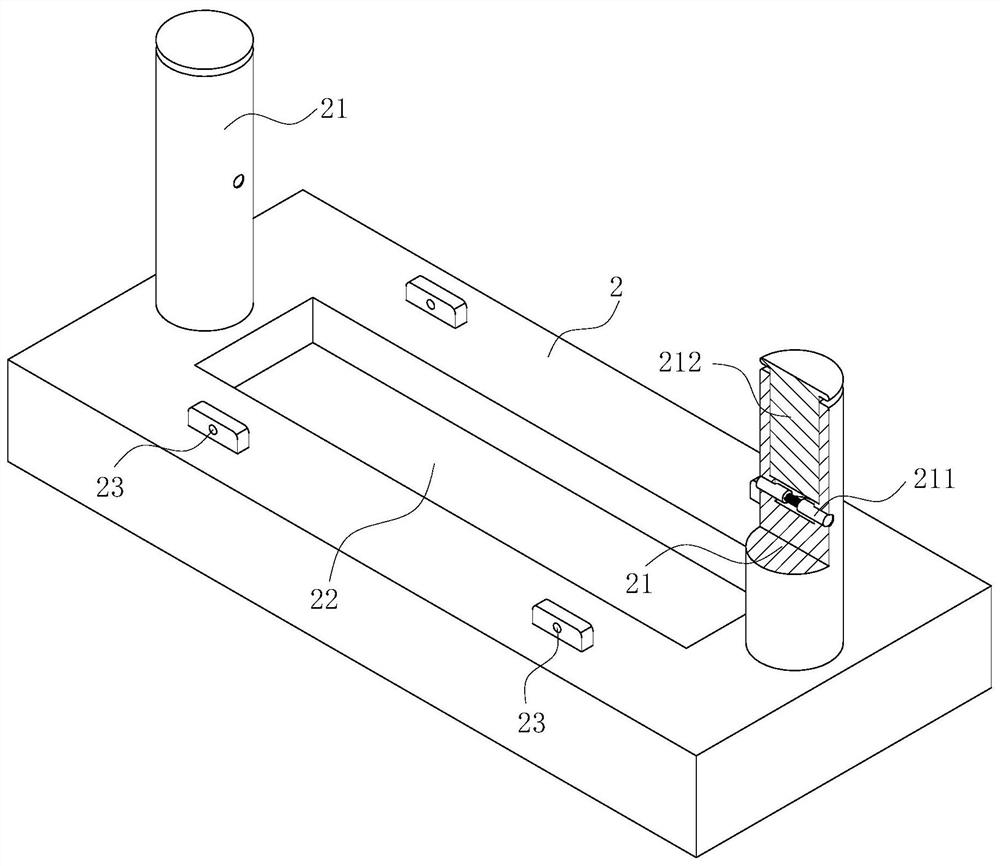

[0035] As an embodiment of the present invention, the fixed mold 1 is provided with a movable chamber 2 151; the center line of the movable chamber 151 is perpendicular to the bottom surface of the lower cavity 13 on the fixed mold 1; the movable chamber 2 Ejector rod 15 is installed in 151; The upper end of described ejector rod 15 is positioned in lower cavity 13, and the upper surface of the upper end of ejector rod 15 is flush with the bottom surface of lower cavity 13; Described ejector rod 15 can Move up and down in the second movable chamber 151; a tension spring one 152 is installed in the second movable chamber 151; ; The fixed mold 1 is provided with an air passage 32; the two ends of the air passage 32 communicate with the two movable chambers 151 and the air bag 31 respectively; the air passage 32 runs through the movable chamber three 423; The through hole 421; the air channel 32 is communicated in the movable chamber three 423 through the through hole 421; when t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com