Multi-functional egg pancake processing machine and using method thereof

A multi-functional, processing machine technology, applied in application, special commodity baking, baking, etc., can solve the problems of heat-sensitive fast solidification, uneven heating, affecting the taste of egg skin, etc., to avoid continuous high-temperature production, The effect of preventing waste of raw materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

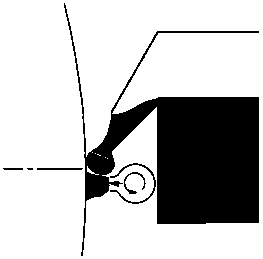

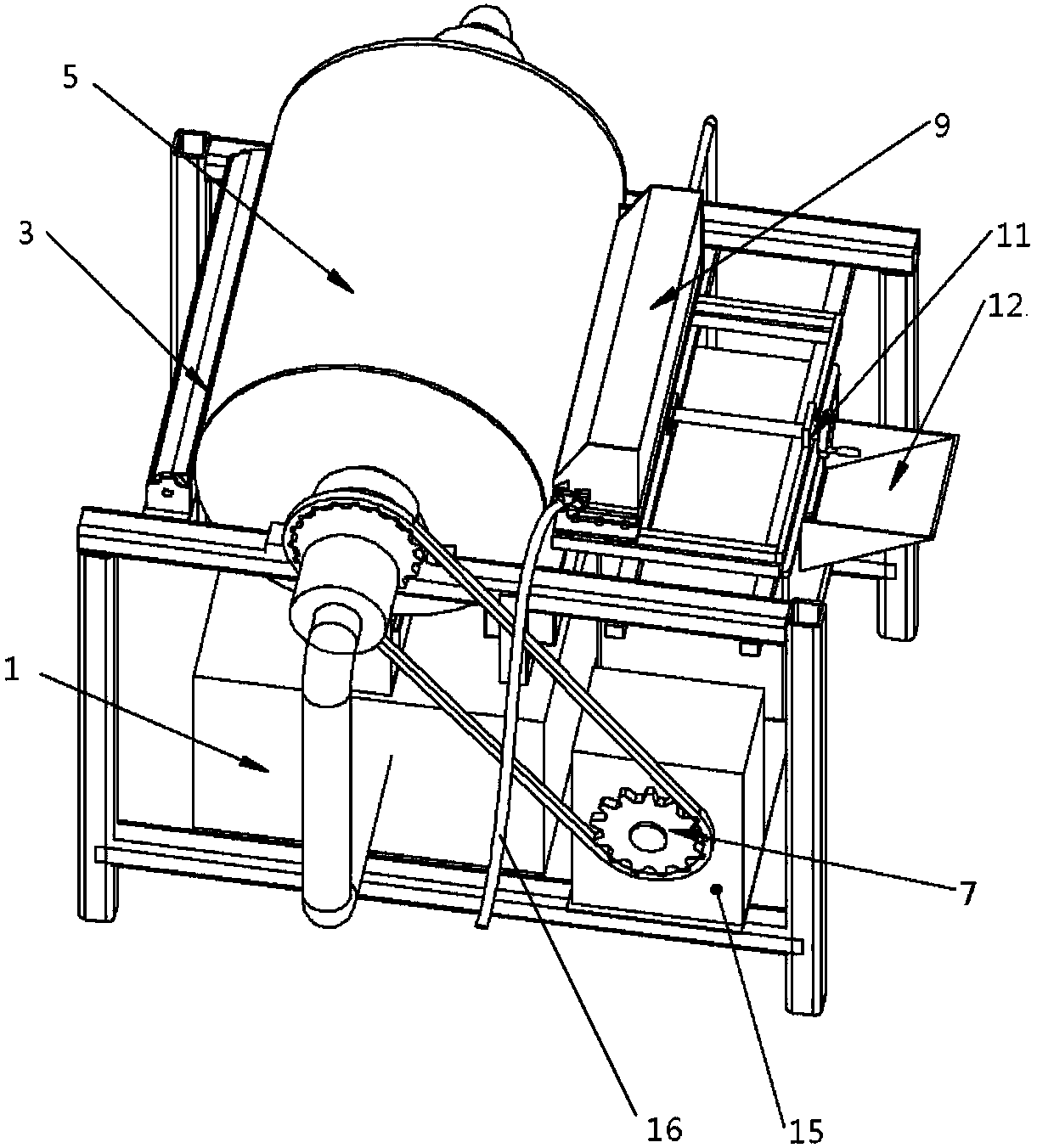

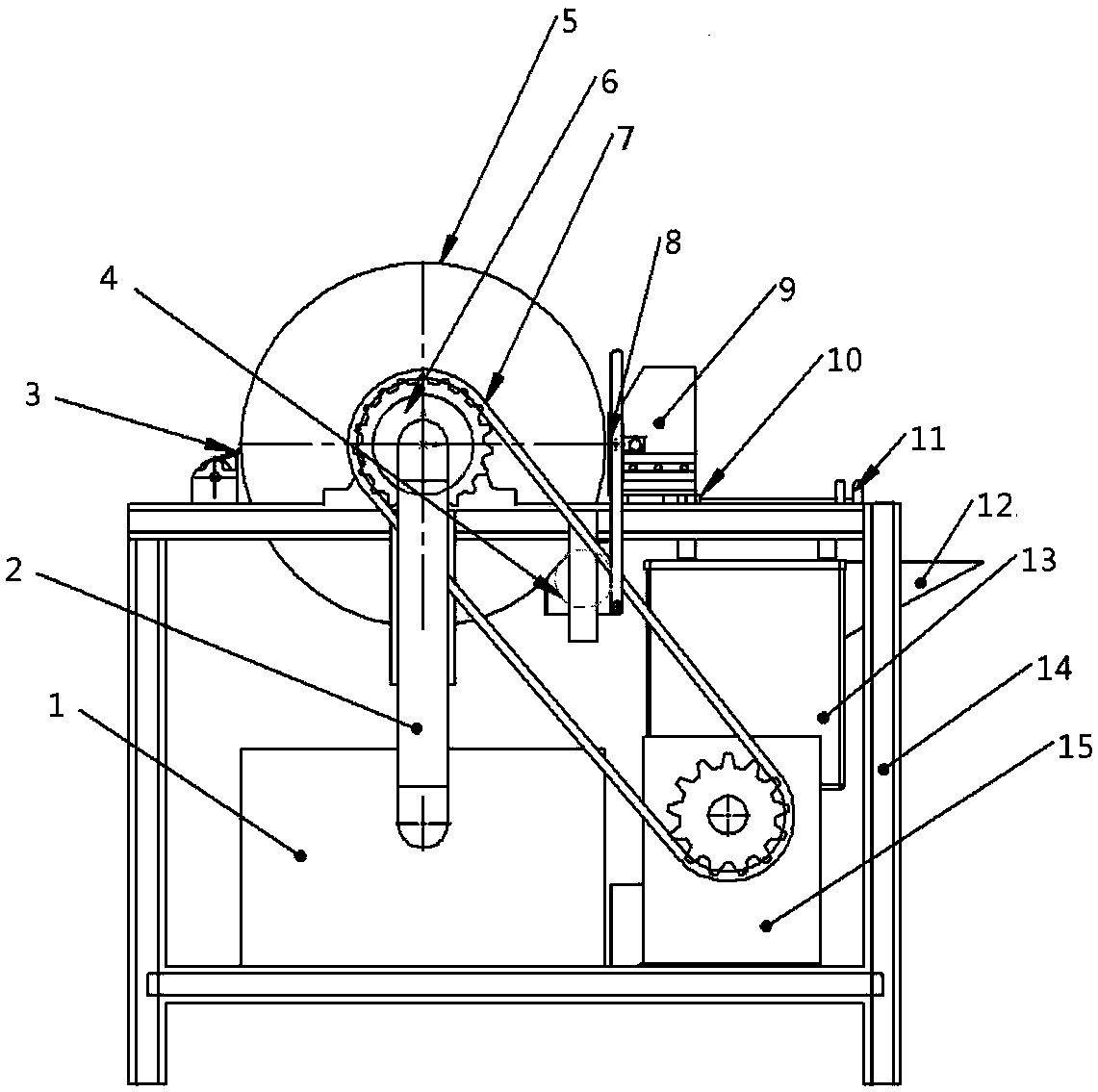

[0026] This embodiment provides a multifunctional egg skin processing machine, the structure of which is as follows: Figure 1 to Figure 5 As shown, it includes a heating drum, an egg liquid supply box 7, an oiling roller 4 and an egg skin scraper 3; the heating drum includes a drum body 5 and a circulation heating device, and the circulation heating device consists of a heating oil tank 1 and an oil delivery pipeline 2, and the heating oil tank The inlet and outlet of the oil pipeline are connected to the oil pipeline, and the oil pipeline is connected with the heating medium inlet and outlet at both ends of the drum body through the circulating oil pump and the rotary pipeline connector 6. The heating drum is installed on the fixed frame 14 and driven to rotate by the driving mechanism. One side of the cylinder is provided with an egg liquid supply box, and the side of the egg liquid supply box 9 near the heating drum is provided with a strip-shaped slit liquid outlet, and th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com