Transferring system and method of health care liquor assembly line

An assembly line, health wine technology, applied in transportation and packaging, synchronization device, bottle filling and other directions, can solve the problems of glass product shaking, low friction, affecting production efficiency, etc., to improve firmness, reasonable structure, and improve stability. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

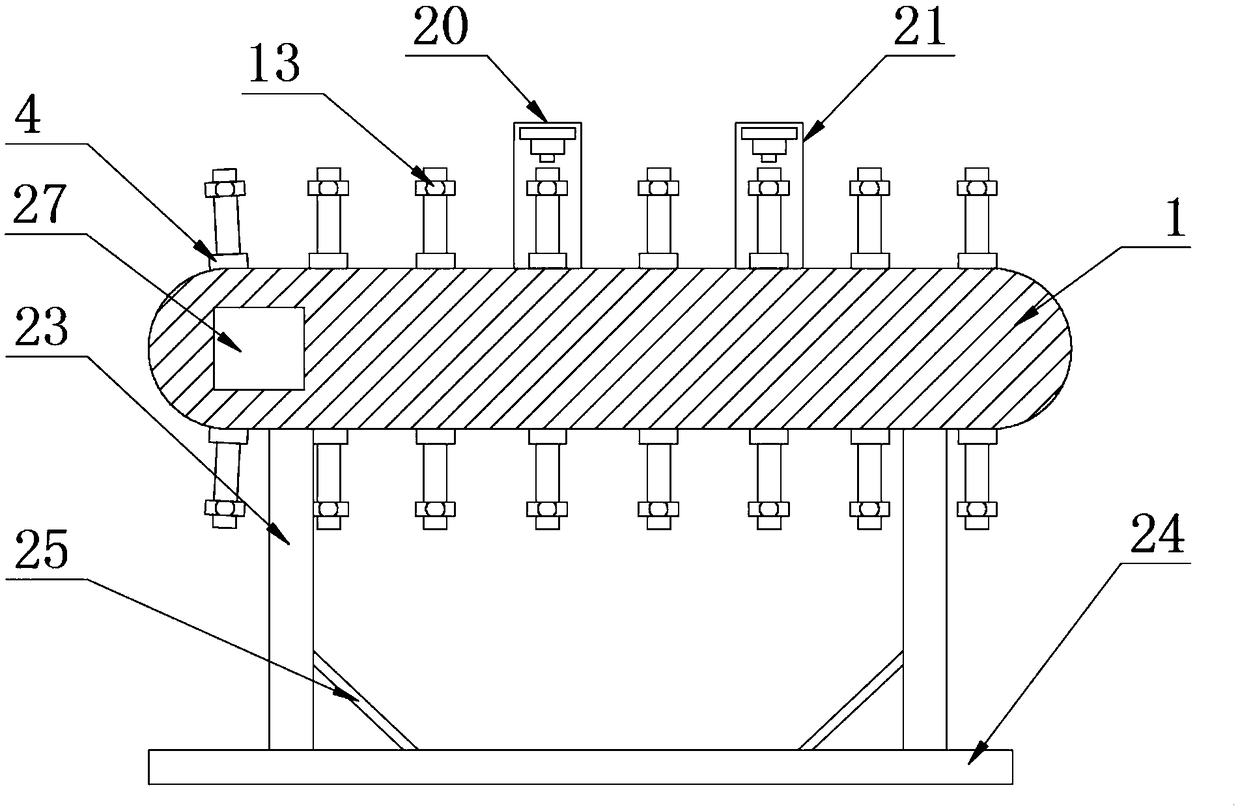

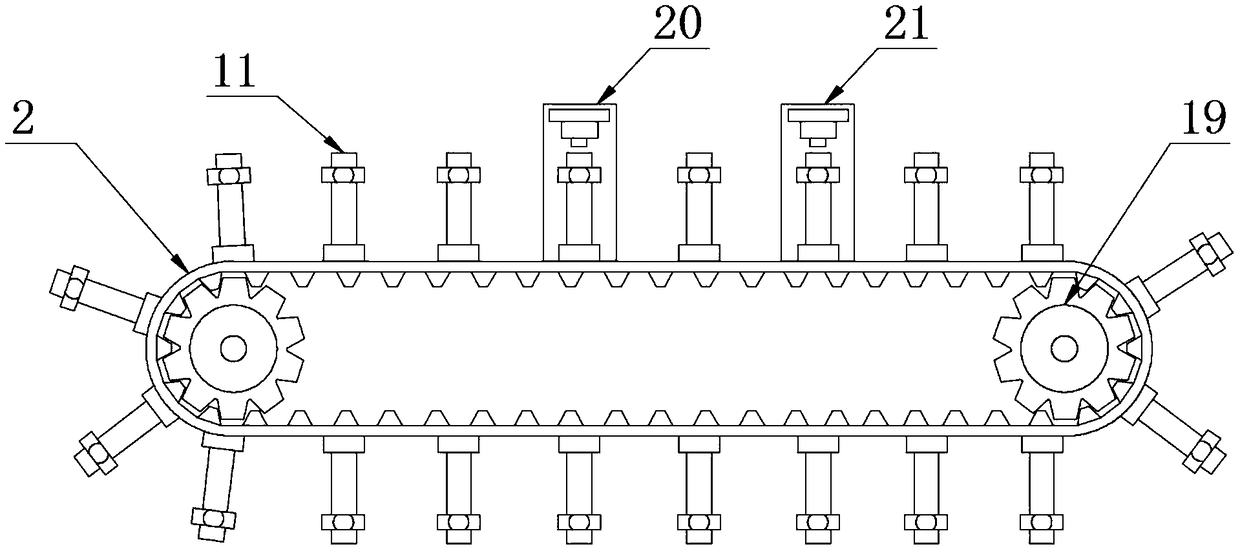

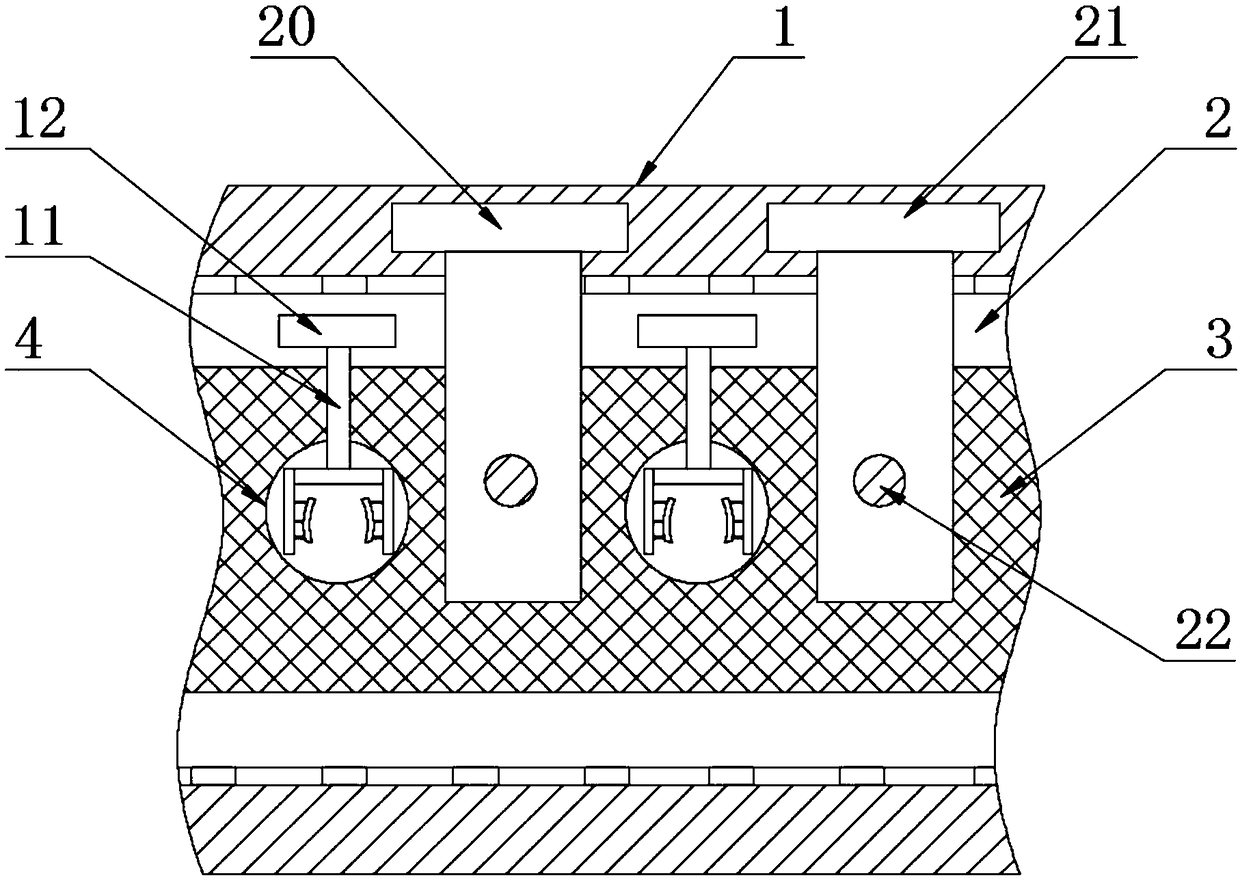

[0030] The present invention provides such Figure 1-6 The shown transfer system of a health care wine assembly line includes a frame 1, fixed rings 2 are arranged on both sides of the inner wall of the frame 1, and a conveyor belt 3 is arranged between two groups of the fixed rings 2. A plurality of first fixing devices 4 are uniformly arranged on the surface of the belt 3, and the first fixing devices 4 include a fixing plate 5, a first fixing plate 6 is arranged on the top of the fixing plate, and both sides of the first fixing plate 6 are provided with The first splint 7, the opposite side of the first splint 7 is provided with a first arc-shaped splint 8, and a plurality of first compression springs 9 are uniformly arranged between the first arc-shaped splint 8 and the first splint 7, One side of the first fixed plate 5 is provided with a first connecting rod 10, one side of the first connecting rod 10 is provided with a supporting rod 11, one side of the supporting rod 1...

Embodiment 2

[0041] A transfer method for a health wine assembly line, including the transfer system for a health care wine assembly line, further comprising the following steps:

[0042] S1: the PLC controller 27 controls the rotation of the motor, and the rotation of the motor drives the rotation of the gear;

[0043] S2: the gear and the inner wall of the fixed ring 2 mesh with each other, so that the conveyor belt 3 can be driven to rotate, and the PLC controller 27 can detect the glass bottle through the photoelectric sensor 22;

[0044] S3: When the photoelectric sensor 22 detects that the glass bottle is running in front of the filling mechanism 20 and the capping mechanism 21, the PLC controller 27 temporarily turns off the motor, so that the glass bottle stops in front of the filling mechanism 20 and the capping mechanism 21;

[0045] S4: the PLC controller 27 controls the filler and the capper to fill and cap the glass bottle;

[0046] S5: When the glass bottle moves on the conv...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com