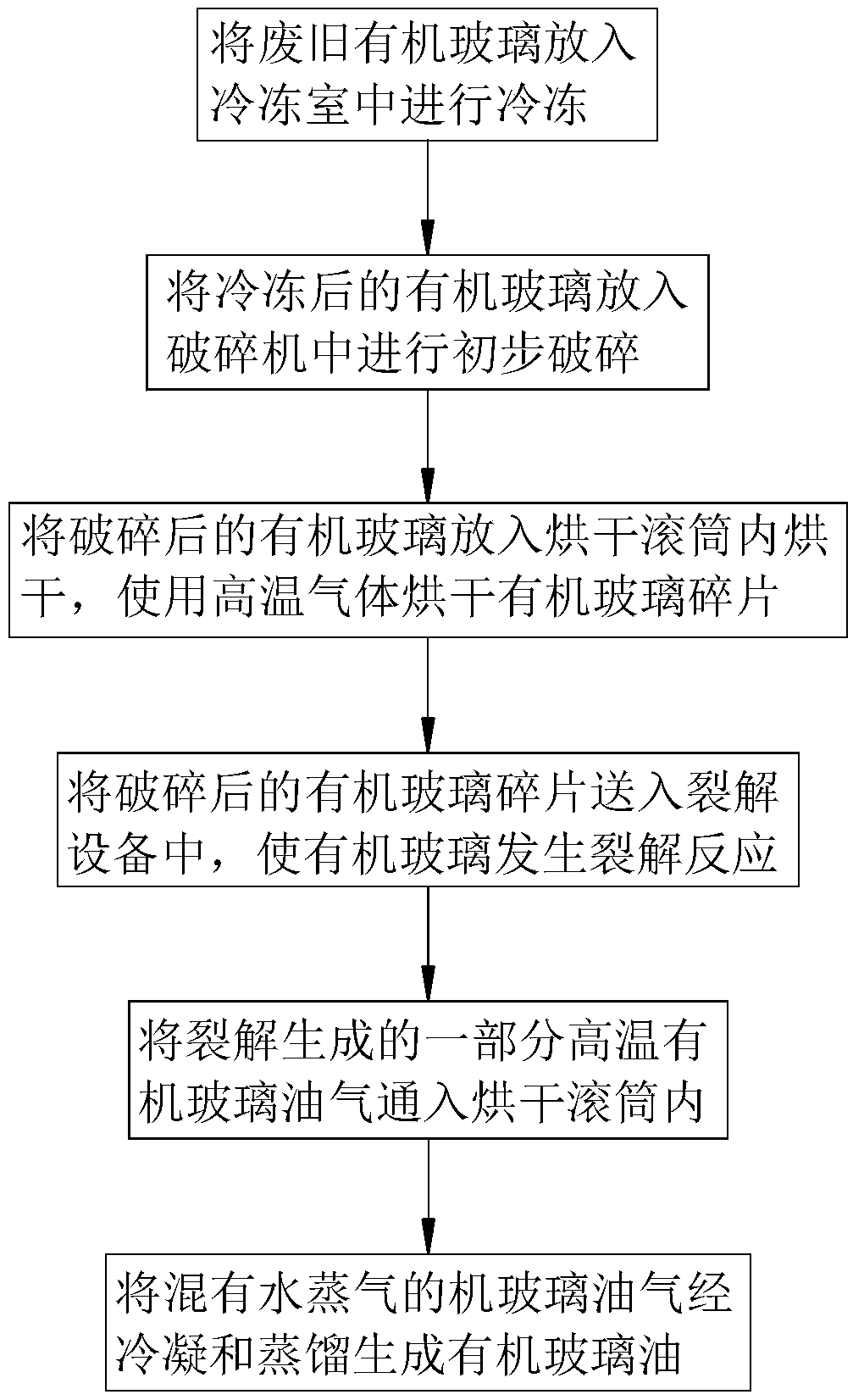

Waste plexiglass recycling method

A technology of plexiglass and recycling method, which is applied in the direction of plastic recycling and recycling technology, which can solve the problems of raw material accumulation, uneven distribution, and affecting the efficiency of cracking reaction, and achieve the effect of accelerating the decomposition speed and improving the efficiency of cracking reaction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

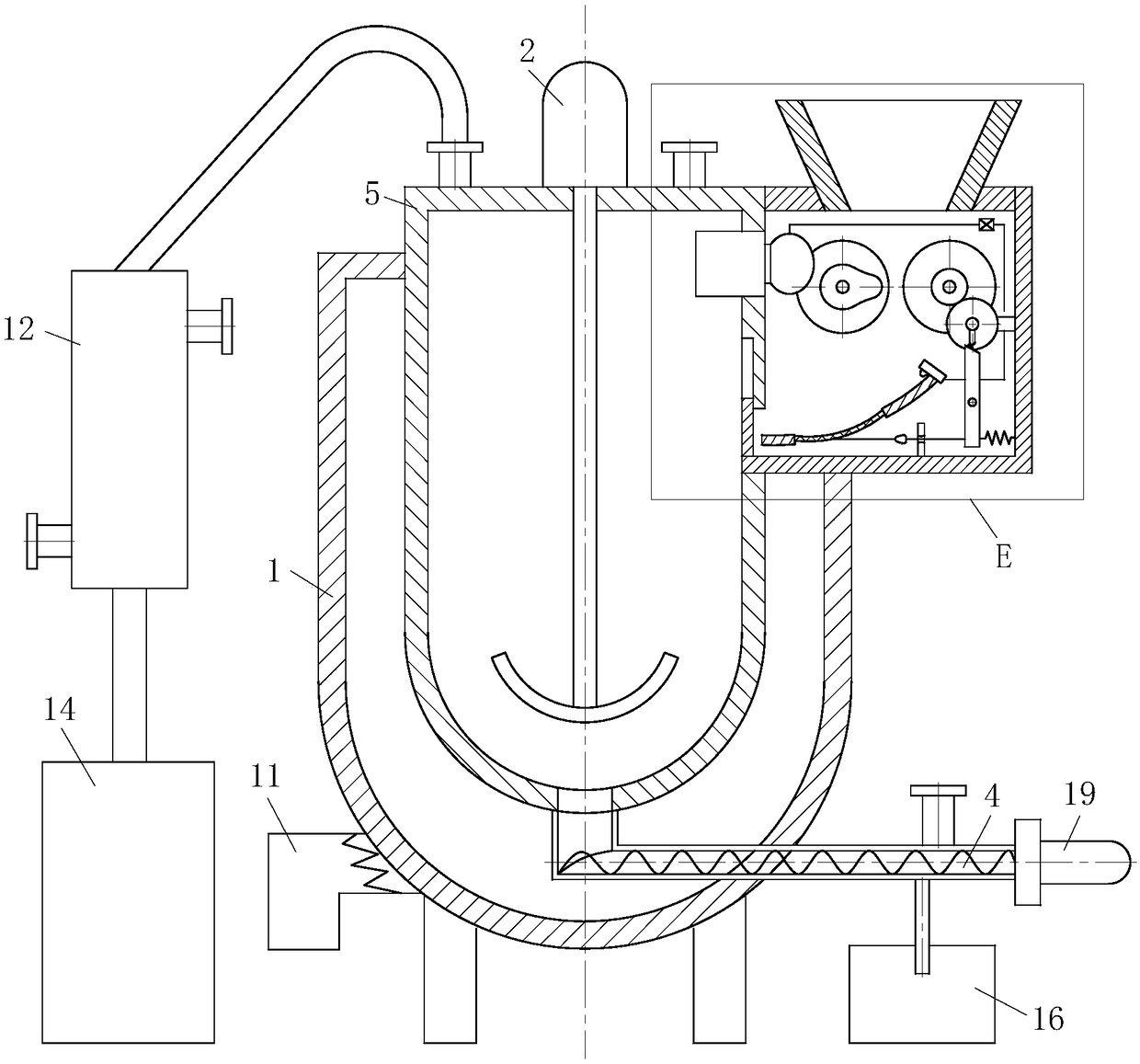

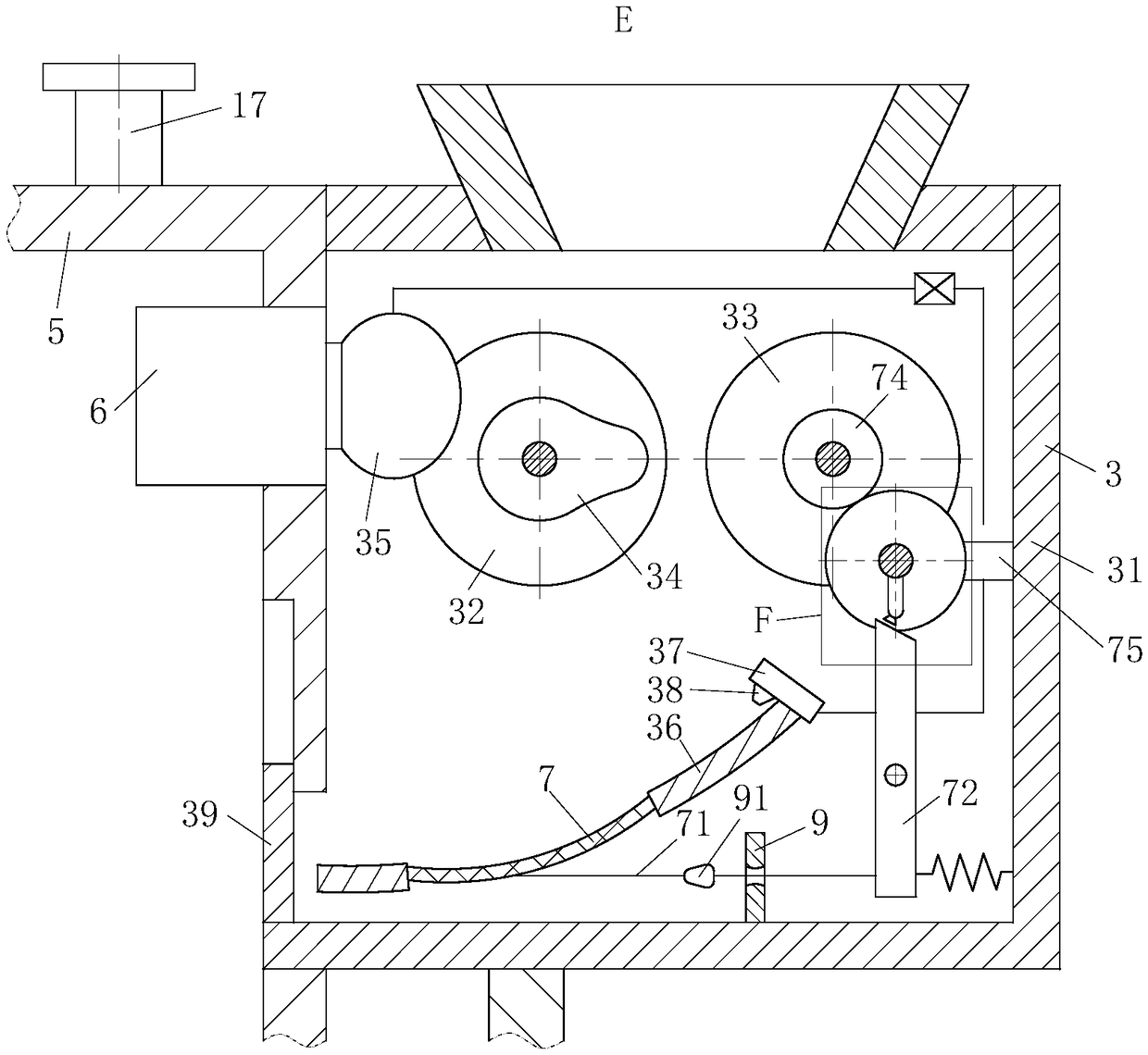

[0038] As an embodiment of the present invention, a filter box 6 is fixedly installed in the upper right corner of the furnace body 1 , the filter box 6 communicates with the airbag 35 , and a check valve is provided between the filter box 6 and the airbag 35 . Using the suction effect of the air bag 35, the high-temperature airflow inside the furnace 5 sends the organic glass particles into the furnace 5, preheats the raw materials, accelerates the decomposition speed of the organic glass particles in the furnace 5, and improves the cracking reaction efficiency of the organic glass particles .

[0039] As an embodiment of the present invention, the middle part of the arc-shaped guide plate 36 is provided with a notch, and the arc-shaped rubber plate 7 is fixedly connected to the inside of the notch, and the bottom of the arc-shaped rubber plate 7 is fixedly connected to one end of the stay rope 71. The other end of the stay cord 71 is fixedly connected to the lower end of the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com