Press roller cleaning mechanism of lithium battery pole piece rolling machine

The technology of a cleaning mechanism and rolling machine is applied to cleaning methods and utensils, cleaning methods using liquids, cleaning methods using tools, etc., which can solve the problems of unsatisfactory cleaning effect and low efficiency, and achieve consistency and ensure Uniform coating and reduced usage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

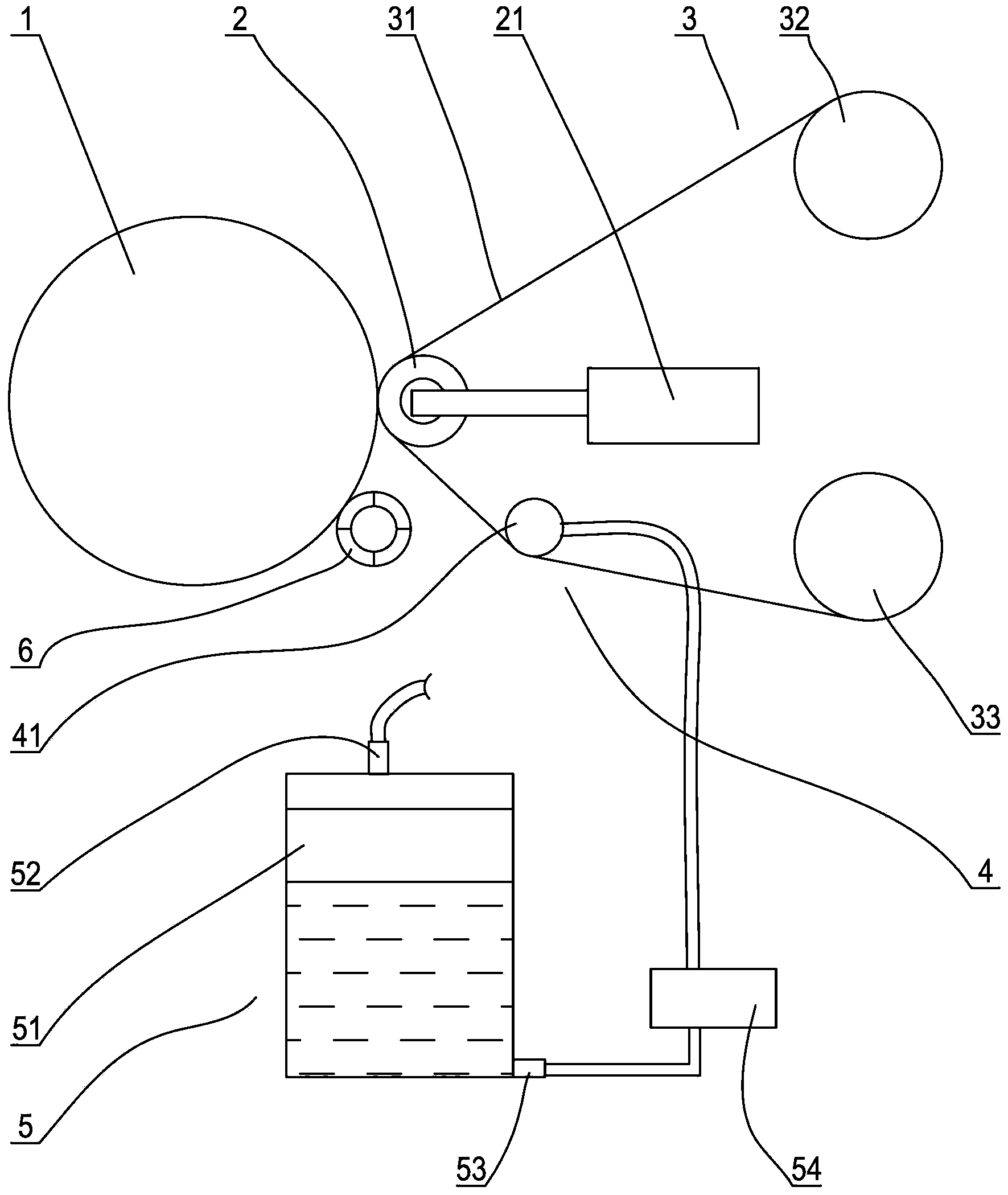

[0034] Embodiment 1: The roller cleaning mechanism of the lithium battery pole piece rolling machine of the present invention includes two cleaning units, which are respectively used to clean the upper and lower rollers, figure 1 Only one of the pressure rollers and the cleaning unit are shown in the figure. The cleaning unit includes a follower roller 2 arranged in parallel with the pressure roller 1, a coil conveying device 3 for taking and receiving the cleaning roll 31, and a cleaning roll for soaking the cleaning roll. The infiltration device 4.

[0035] The follower roller is located on the sending side of the pressure roller, and is pushed and translated by two cylinders 21 located on both sides, thereby having a working position pressing against the pressure roller and a standby position away from the pressure roller. In order to facilitate the control of the stroke of the cylinder piston rod and avoid the impact of the follower roller on the pressure roller, the end o...

Embodiment 2

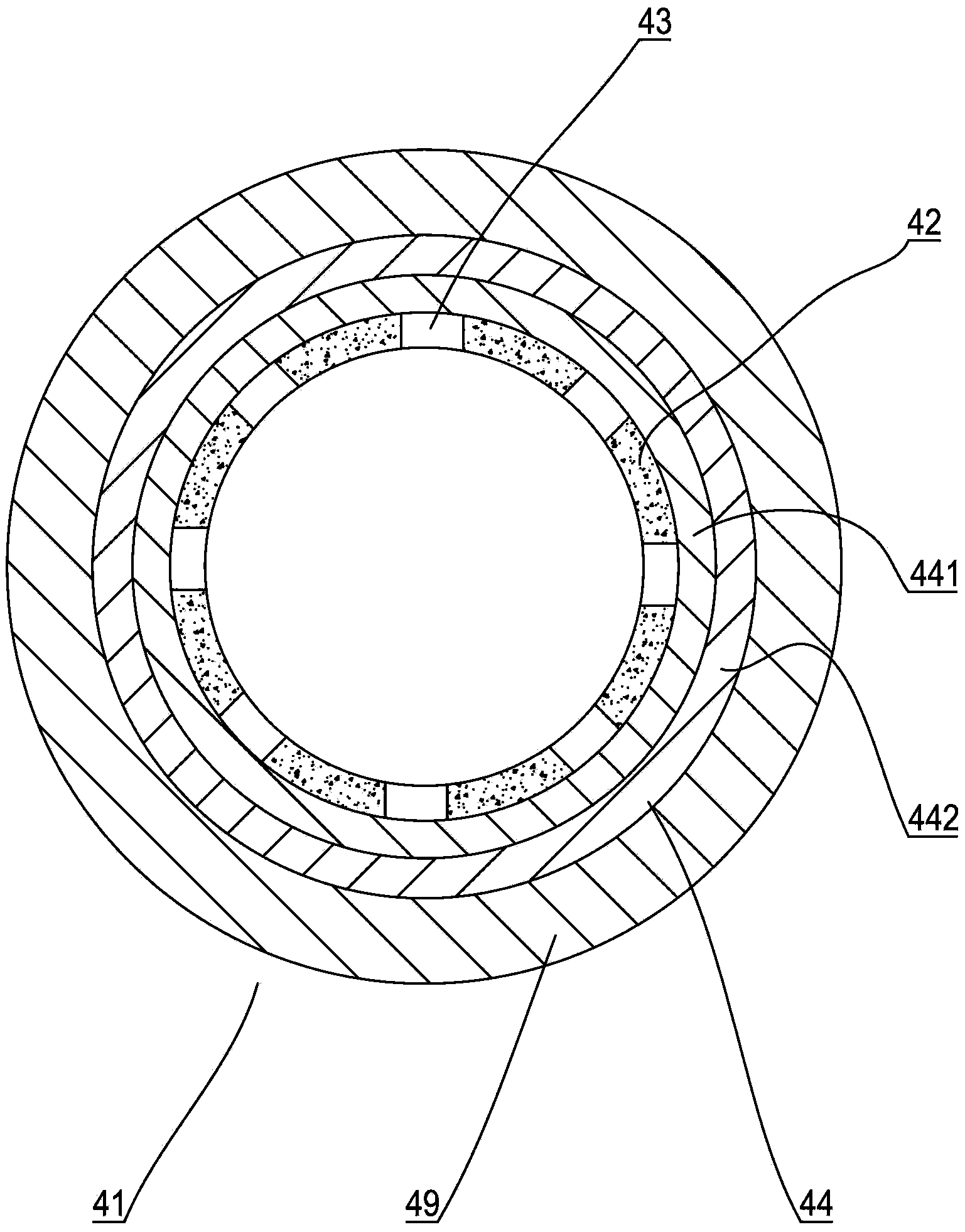

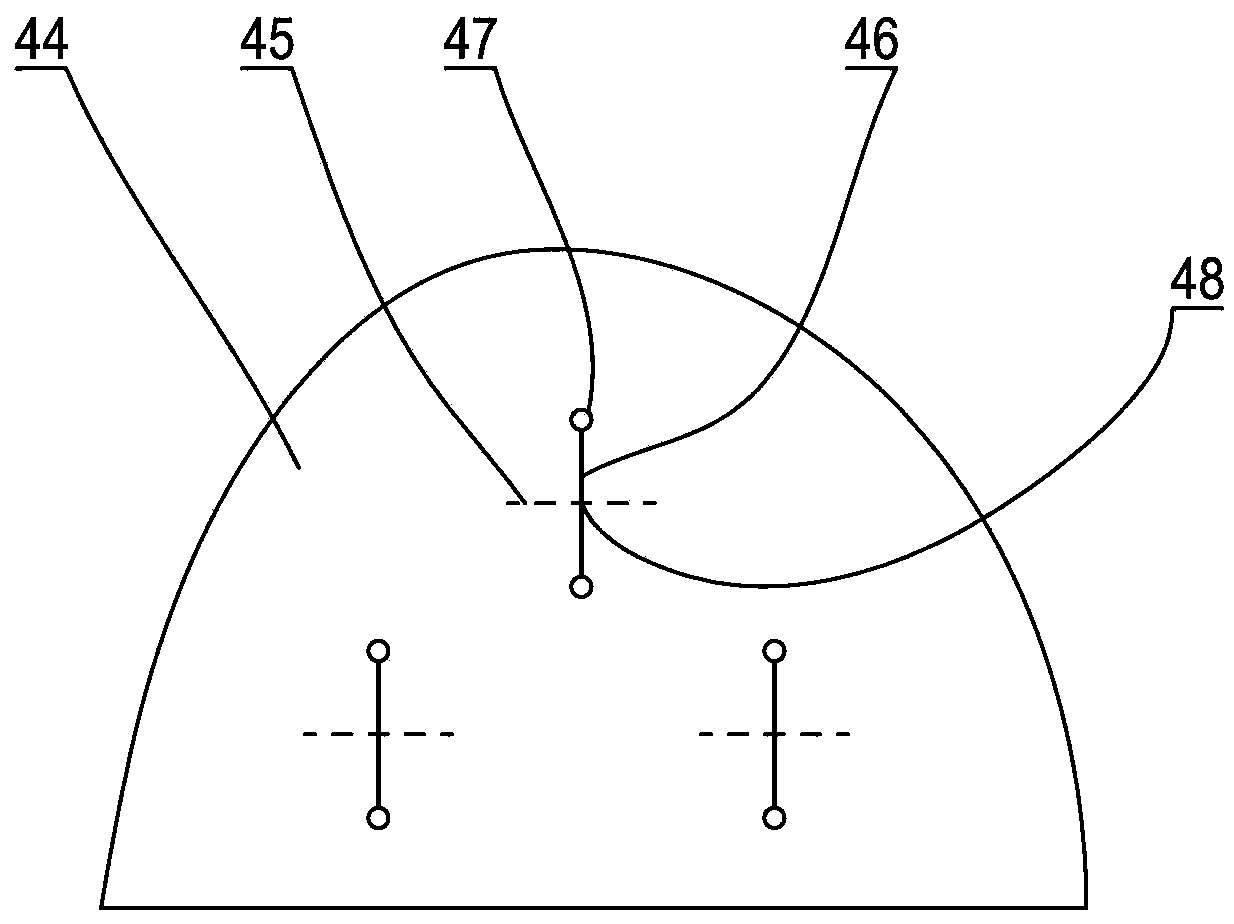

[0043] Embodiment two: if Image 6 As shown, the basic structure and cleaning process of this embodiment are the same as those of Embodiment 1, the difference is that a pinch roller 7 that is parallel and close to the soaking roller is added to the soaking device, and the cleaning roll is drawn from the soaking roll and the clamping roller. Passing through the nip between the pinch rolls, the dip roll is on the outside of the cleaning web, and the pinch roll, like the follower roll, is on the inside of the cleaning web. Such as Figure 7 As shown, the damping layer in the soaking roller adopts a single-layer structure, and the circumferential surface of the damping layer is provided with a number of evenly distributed outwardly convex seepage cylinders 443, and the seepage cylinders are embedded in the liquid seepage layer of the outer layer, and the seepage cylinders There is a liquid outlet hole 444 penetrating through the inner surface of the damping layer, and a number of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com