Method for manufacturing air condition compressor balance block

An air-conditioning compressor and a manufacturing method technology, applied in the field of mechanical engineering, can solve the problems that the mechanical properties of castings are inferior to forgings, it is difficult to manufacture compressor balance blocks, and the quality of castings is not stable enough, so as to achieve high product quality, improve product market competitiveness, The effect of saving cutting time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0040] The following are specific embodiments of the present invention and in conjunction with the accompanying drawings, the technical solutions of the present invention are further described, but the present invention is not limited to these embodiments.

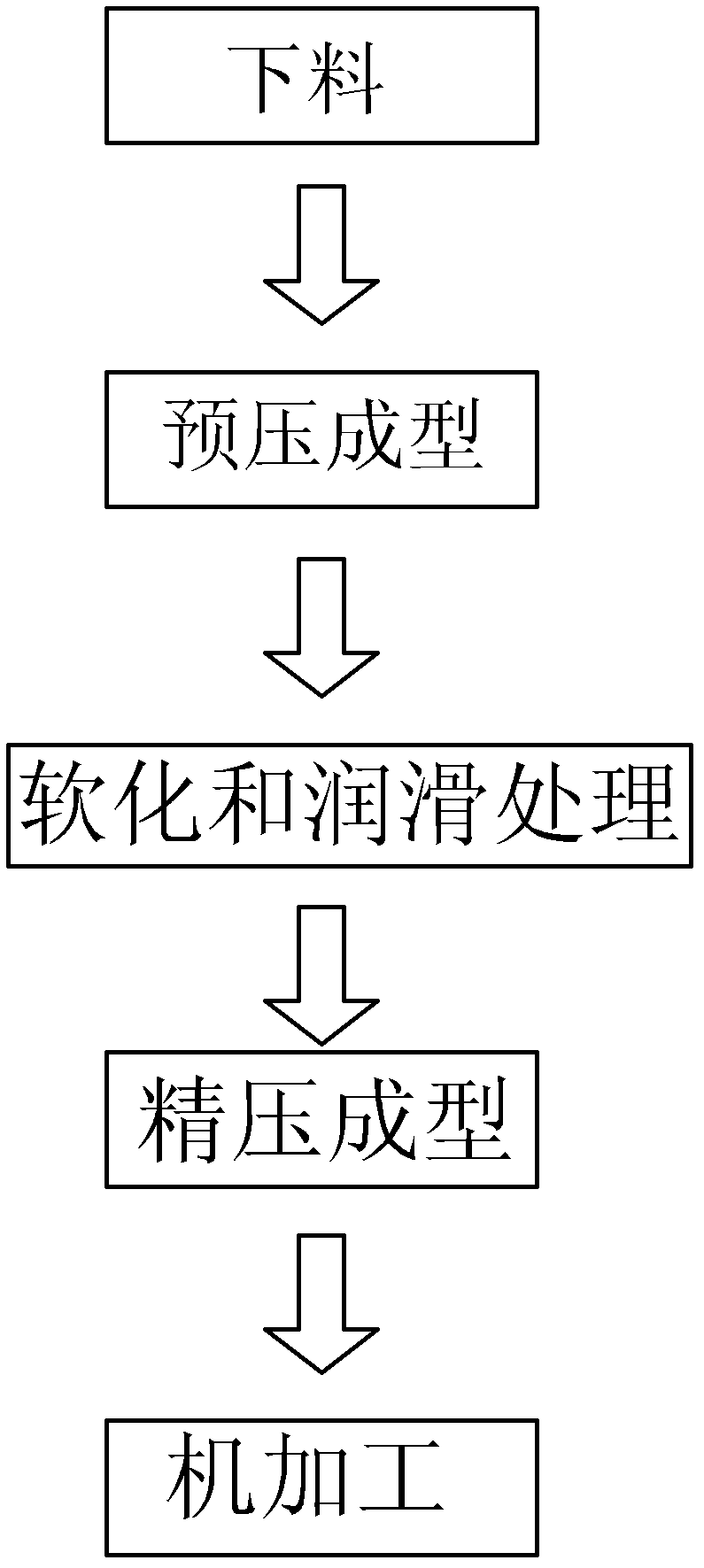

[0041] Such as figure 2 As shown, using this production method to make the balance weight is carried out in the following steps: the compressor balance weight is made of high manganese steel, such as 3Cr4Mn23, 20Mn23Al and other high manganese non-magnetic steel.

[0042] According to the shape and size of the balance weight of the air-conditioning compressor, the blank corresponding to the shape and size of the balance weight is designed; generally speaking, the cross section of the blank is rectangular or "convex". The section of the blank given in this implementation is rectangular and "convex", such as image 3 and Image 6 .

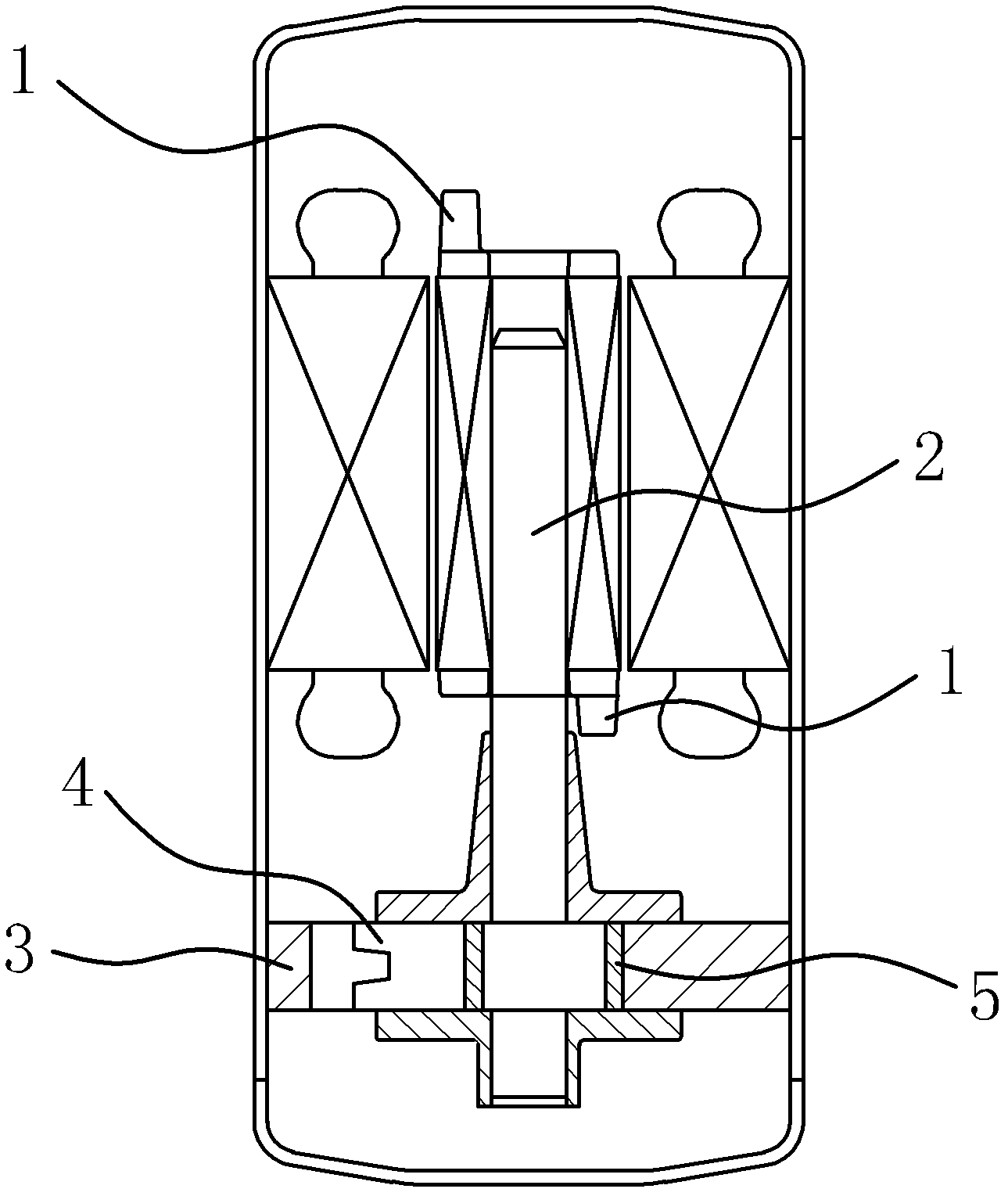

[0043] Such as Figure 2 to Figure 8 As shown, the profile that is exactly the same as ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com