Quaternary amine modified straw material for removing nitrate in water body, preparation method and application

A technology for modifying straw and nitrate, which is applied in chemical instruments and methods, biofuels, water pollutants, etc., can solve the problem of low nitrate nitrogen adsorption, improve activity, improve reaction efficiency, and reduce preparation costs Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

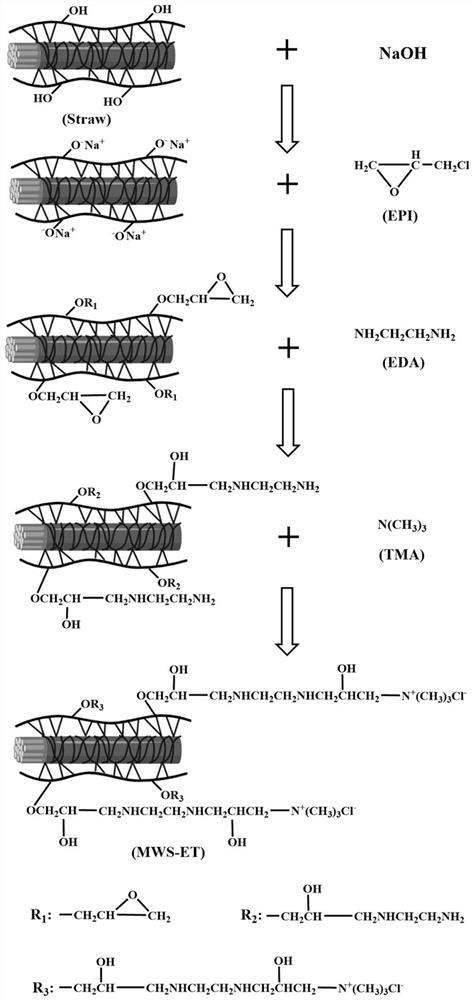

[0070] Preparation of quaternary amine modified straw MWS-ET:

[0071] ①The air-dried wheat straw was washed with distilled water, dried and pulverized, and then sieved. The straw with a particle size of 0.2-0.9 mm (20-80 mesh) was selected and dried at 60 °C for 24 h (named WS), sealed in a bag, and stored. in a glass desiccator.

[0072] (2) Take 2.0 g of straw and add 30 mL of 10% (w / v) NaOH solution for alkalization pretreatment at room temperature for 2 h, then squeeze, filter and dehydrate.

[0073] ③ Then put the straw in a 250 mL three-necked flask, add 30 mL of epichlorohydrin, and stir at 90 °C for 1 h.

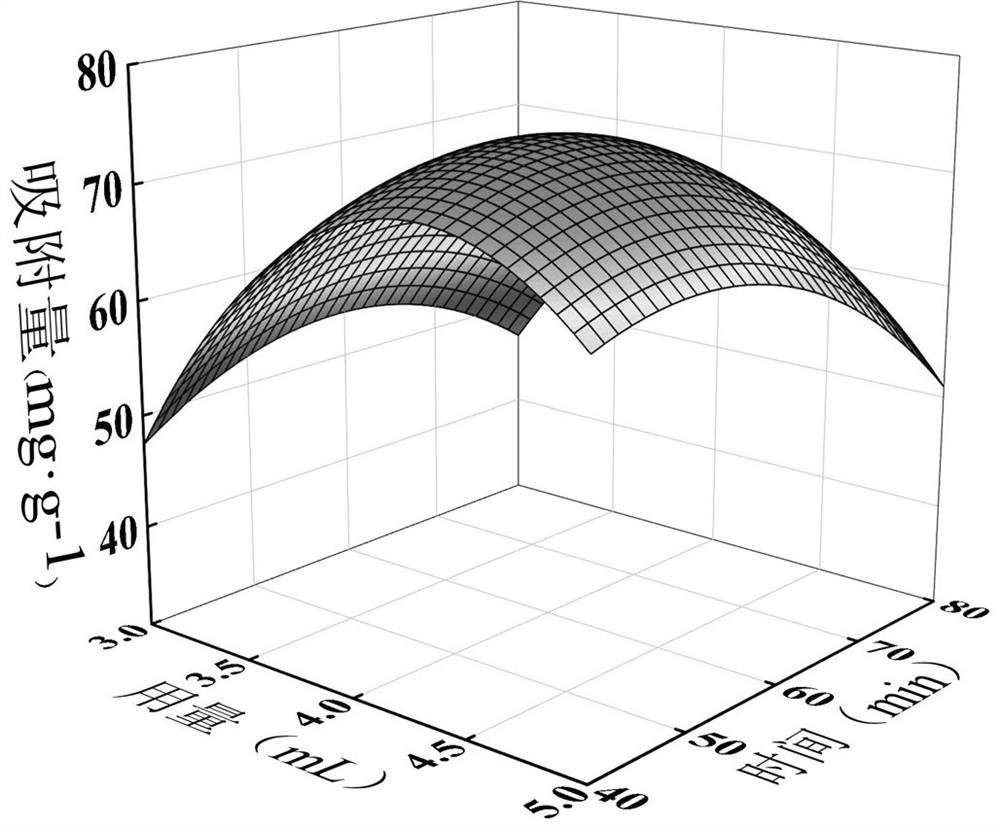

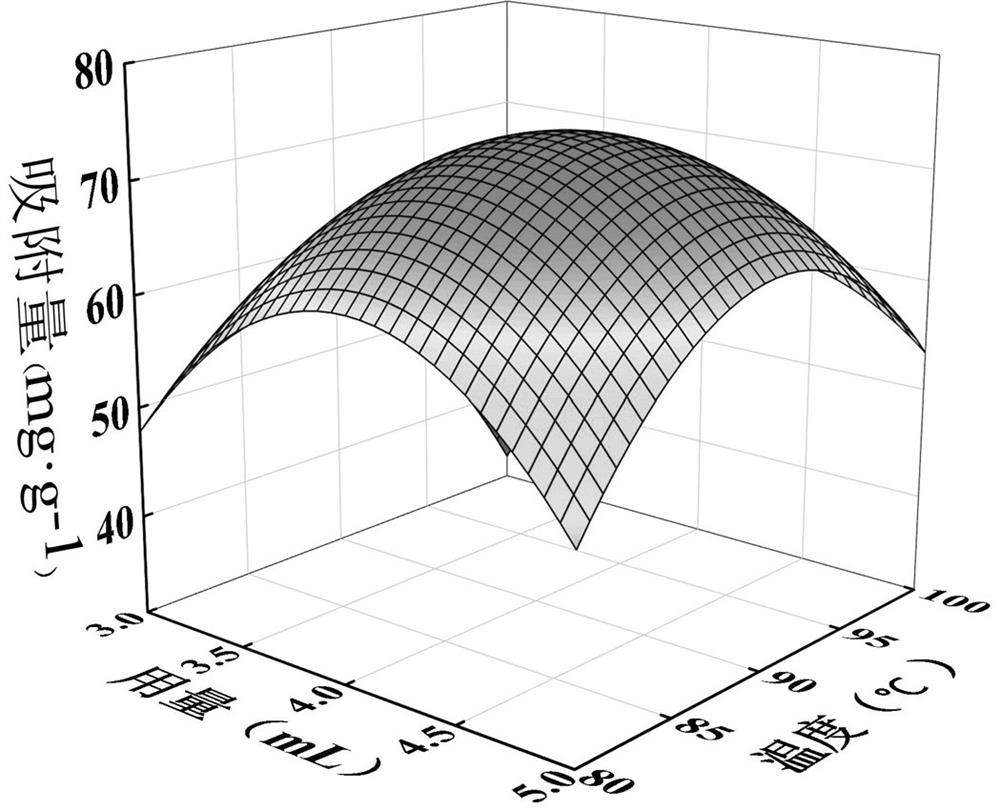

[0074] 4.2 mL of ethylenediamine was slowly added, and the reaction was carried out at 89.5 °C for 54.0 min. 20 mL of trimethylamine solution was added to react at 90 °C for 3 h.

[0075] ④ The product was adjusted to neutrality with sodium hydroxide and hydrochloric acid, washed with ethanol and deionized water, and dried in an oven at 60 °C for use.

[0076] T...

Embodiment 2

[0078] Preparation of quaternary amine modified straw MWS-ET1:

[0079] ①The air-dried wheat straw was washed with distilled water, dried and pulverized, and then sieved. The straw with a particle size of 0.2-0.9 mm (20-80 mesh) was selected and dried at 60 °C for 24 h (named WS), sealed in a bag, and stored. in a glass desiccator.

[0080] ② Take 2.0 g of straw and add 30 mL of 10% (w / v) NaOH solution to alkalize it for 2 h at room temperature, and dehydrate it by vacuum freeze-drying to make the moisture content reach 15%-25%.

[0081] ③ Mix isopropanol with straw samples by fumigation treatment, so that the water / isopropanol ratio is 90%-100%.

[0082] ④ Then put the straw into a 250 mL three-necked flask, add 30 mL of epichlorohydrin, and stir at 90 °C for 1 h. 4.2 mL of ethylenediamine was slowly added, and the reaction was carried out at 89.5 °C for 54 min. 20 mL of trimethylamine solution was added to react at 90 °C for 3 h.

[0083] ⑤ The product was adjusted to ne...

Embodiment 3

[0085] Preparation of quaternary amine modified straw MWS-ET2:

[0086] ①The air-dried wheat straw was washed with distilled water, dried and pulverized, and then sieved. The straw with a particle size of 0.2-0.9 mm (20-80 mesh) was selected and dried at 60 °C for 24 h (named WS), sealed in a bag, and stored. in a glass desiccator.

[0087] ② Take 2.0 g of straw and add 30 mL of 10% (w / v) NaOH solution for alkali pretreatment at room temperature for 2 h, dehydrate by vacuum freeze-drying method to make the moisture content reach 15%-25%, and then use fumigation The treatment method is to mix isopropanol with the straw sample (for example, the ratio of straw sample to isopropanol is 2:1.8-2 in g:mL), so that the water / isopropanol ratio is 90%-100%.

[0088] ③ Then put the straw in a 250 mL three-necked flask, add 20 mL of epichlorohydrin, and stir at 90 °C for 1 h. 4.2 mL of ethylenediamine was slowly added, and the reaction was carried out at 89.5 °C for 54 min.

[0089] ④A...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| adsorption capacity | aaaaa | aaaaa |

| adsorption capacity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com