Waste gas treatment equipment for environmental engineering

A technology for waste gas treatment equipment and environmental engineering, applied in the field of environmental engineering, can solve problems such as equipment safety hazards, heat escape, and inconvenience for workers to clean up, and achieve the effects of short replacement time, safe and convenient use, and avoidance of heat waste.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

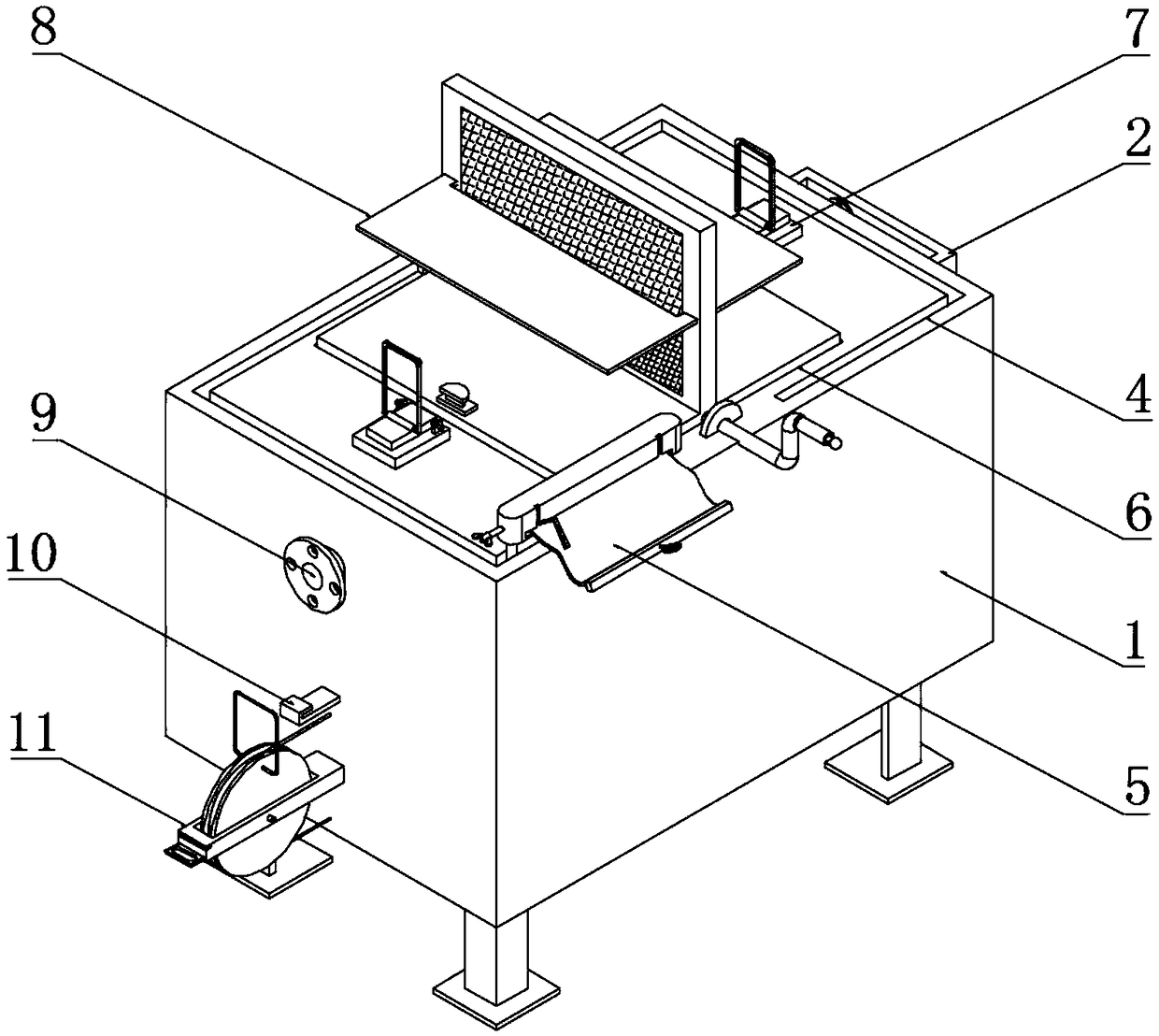

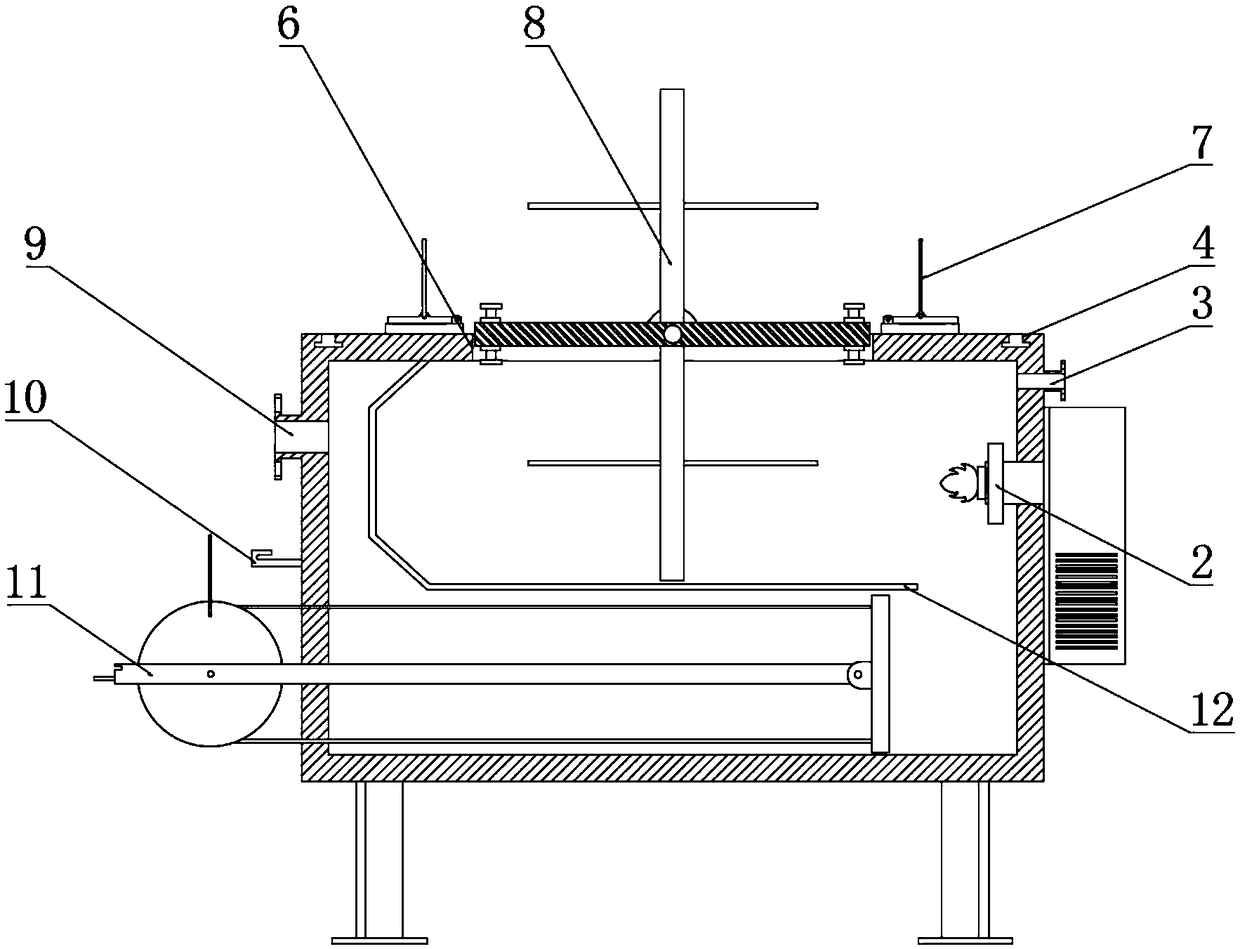

[0027] Example: such as Figure 1-5 As shown, the present invention provides a technical solution, a waste gas treatment equipment for environmental engineering, including a reaction box 1, a burner 2 is installed on one side of the reaction box 1, and the surface of one side of the reaction box 1 is connected to the top of the burner 2. An air inlet 3 is provided at the corresponding position, and a chute 4 is provided on the outer ring of the upper surface of the reaction box 1 .

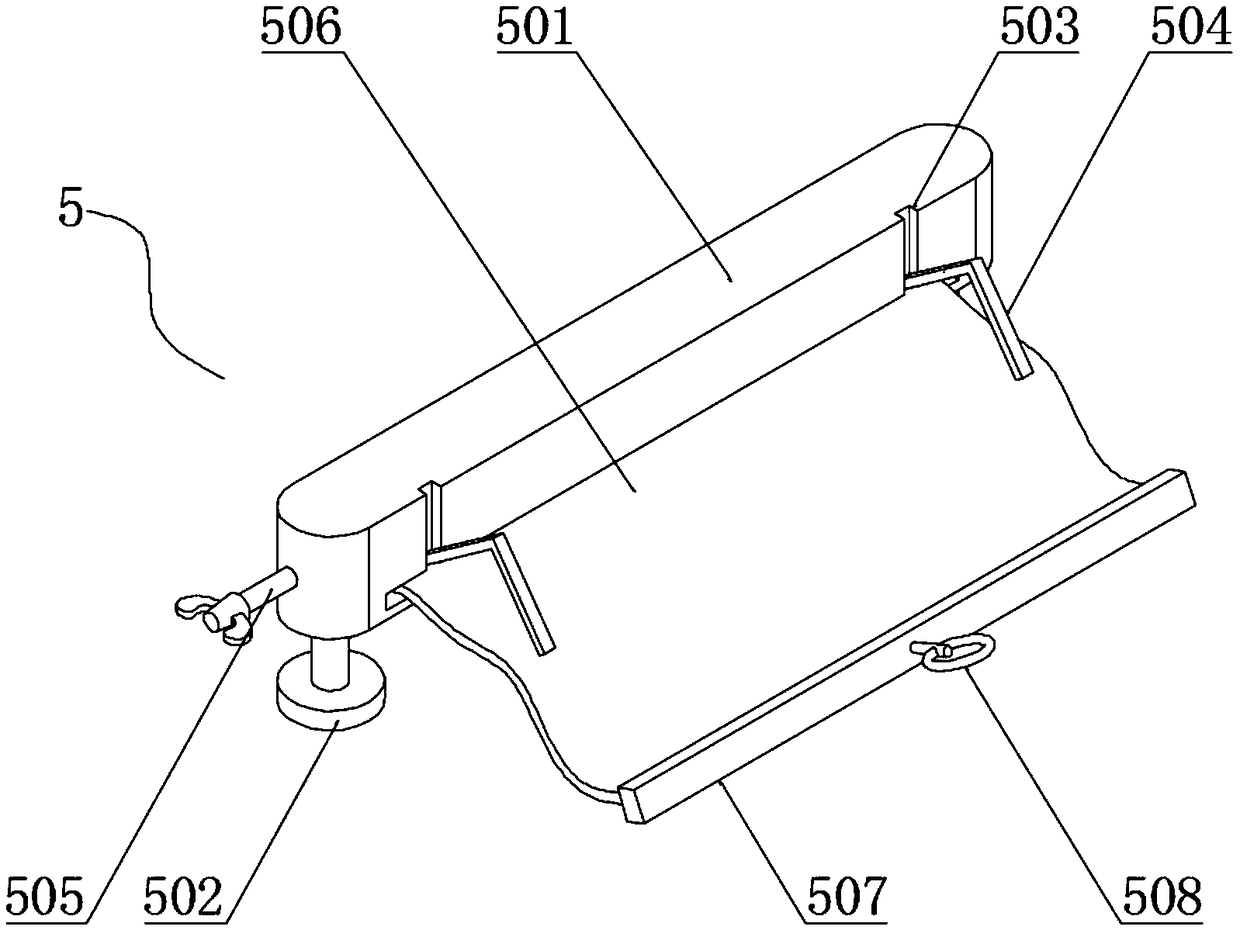

[0028] A detection mechanism 5 is installed above the chute 4. The detection mechanism 5 includes a storage box 501, a sliding column 502, a storage groove 503, a sealing rod 504, a storage shaft 505, a plastic film 506, a limit plate 507 and a pull ring 508, and the storage box 501 Sliding columns 502 are installed at the bottom, in order to ensure that the storage box 501 can maintain a stable movement and steering in the chute 4 through the sliding columns 502, the number of sliding columns 502...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com