Stirring reactor for feeding material uniformly in reaction

A technology for stirring reaction kettles and reaction kettle bodies, which is applied in chemical/physical/physical-chemical stationary reactors, chemical/physical/physical-chemical processes, chemical instruments and methods, etc. The problem of uniformity is achieved to avoid the effect of insufficient response.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

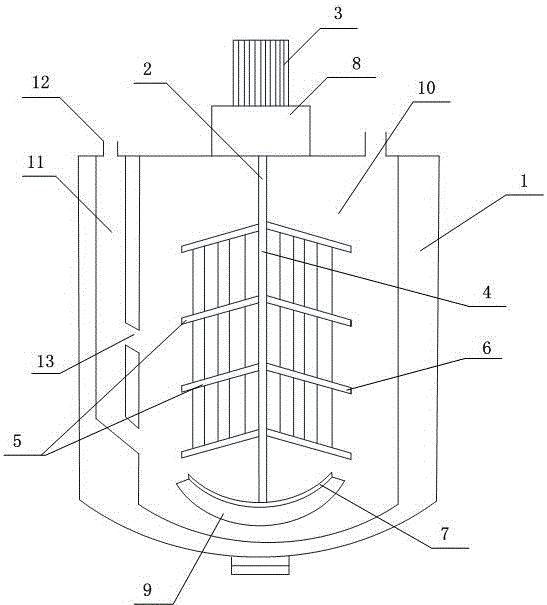

[0035] As shown in the figure, a stirred reactor for uniform feeding in the reaction of the present invention includes a reactor body 1, a stirring device 2, and a motor 3. The top of the reactor body 1 is provided with a feed port, and the bottom of the reactor body is provided with a There is a discharge port; one end of the stirring device extends out of the reactor body and is connected with the motor 3,

[0036] The reactor body comprises a reaction cavity 10 and a feeding cavity 11;

[0037] The feeding cavity has a feeding port 12, and the feeding port is located on the reactor body;

[0038] The feeding cavity communicates with the reaction cavity through at least one connecting pipe 13;

[0039] The connecting pipe has a slope;

[0040] The connecting pipe is arranged in the middle of the reaction chamber;

[0041] The stirring device 2 comprises a stirring shaft 4 and a stirring blade 5 connected to the stirring shaft;

[0042] The stirring blade 5 comprises 4 pa...

Embodiment 2

[0051] On the basis of the above embodiments, the angle between the stirring rod and the stirring shaft is 60-70°; the stirring rod has a certain slope, which is more conducive to stirring.

Embodiment 3

[0053] On the basis of the above embodiments, the stirring device 2 and the reactor body 1 are made of stainless steel, ceramic or PP. Stainless steel is resistant to weak corrosive media such as air, steam, water, and chemically corrosive media such as acid, alkali, and salt, and is suitable for reactions with corrosive media in raw materials. The ceramic and PP materials are suitable for the reaction without raw materials such as acid and alkali, and the materials are light.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com