Method of eliminating primary β grain boundary of tc4 alloy by adding b induction heating in laser additive manufacturing

A technology of induction heating and laser additive materials, which is applied in the direction of additive manufacturing, additive processing, process efficiency improvement, etc., can solve the problems of large anisotropy, high strength, low plasticity, etc. organization effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

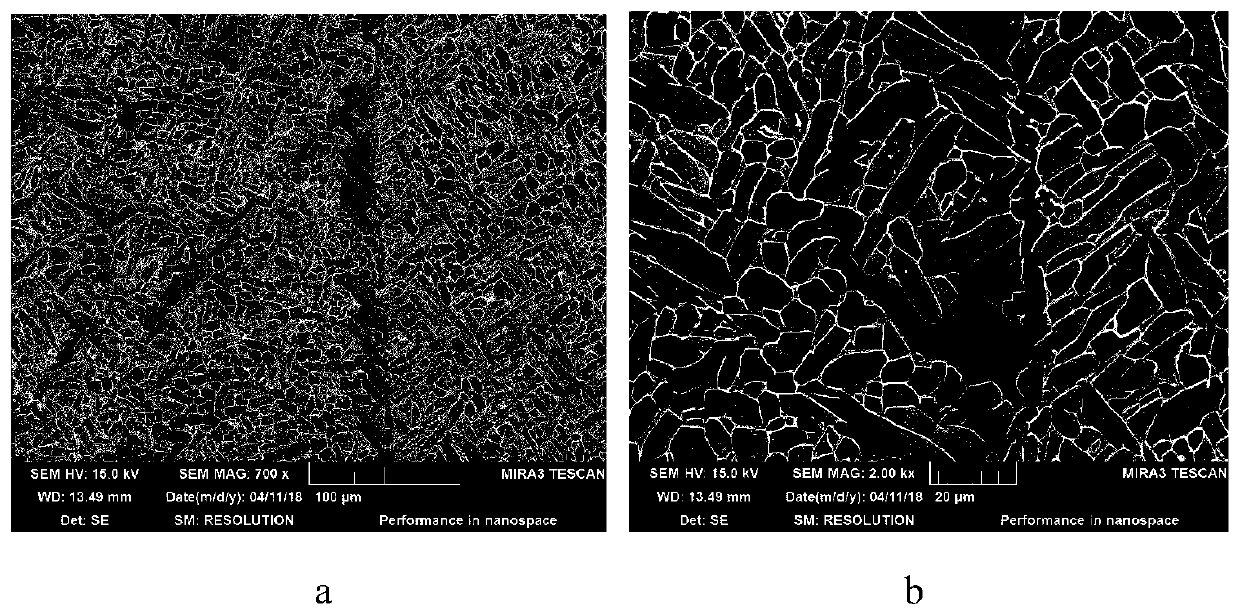

[0030] When the mass proportion of B powder is 0.01%, the microstructure of the sample obtained by the above method is as follows: figure 2 As shown, the original β grain boundary is formed by the boundary line of two parallel rows of flaky α in opposite directions, where figure 2 Middle b is the magnified rendering of a.

Embodiment 2

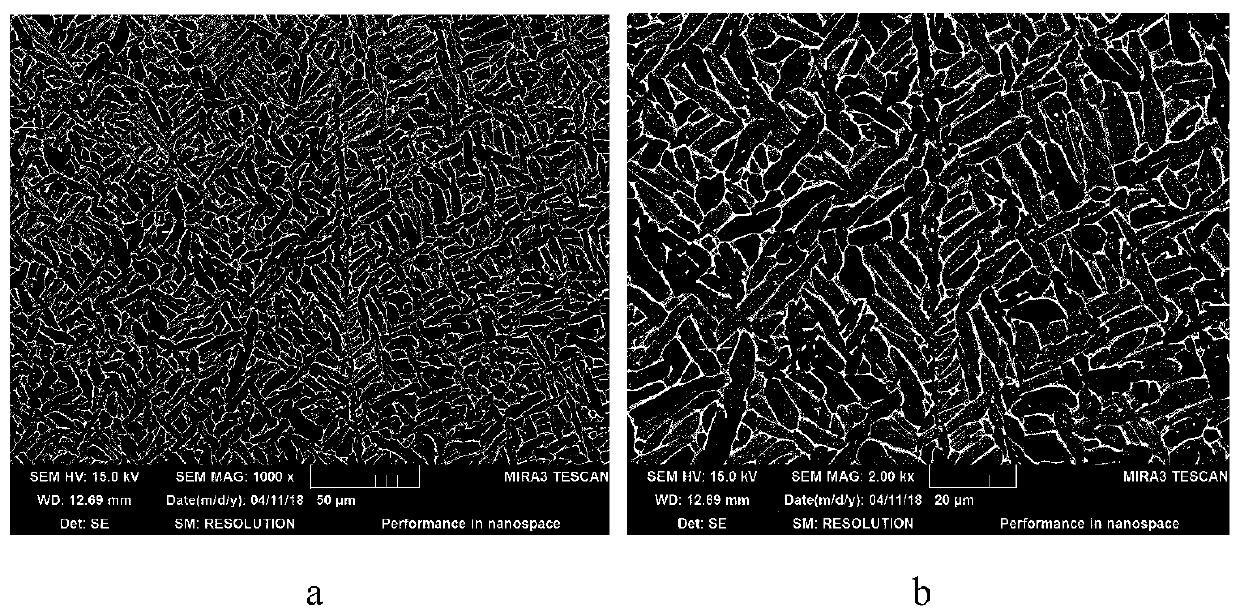

[0032] When the mass ratio of B powder is 0.025%, the microstructure of the sample obtained by the above method is as follows: image 3 As shown, the lamella α arranged in parallel still exists, and the boundary line is formed by the first connected lamella α to form the original β grain boundary, where image 3 Middle b is the magnified rendering of a.

Embodiment 3

[0034] When the mass ratio of B powder is 0.05%, the microstructure of the sample obtained by the above method is as follows: Figure 4 As shown, the grain boundary is mainly dominated by the flaky α that is connected to the first position, and the flaky α arranged in parallel is very small, and the macrostructure is no longer β columnar grains, mainly in the form of flaky grains, of which Figure 4 Middle b is the magnified rendering of a.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com