Method for preparing self-repaired polymer composite material

A composite material and polymer technology, applied in the field of self-healing polymer composite materials, can solve the problems of easy sublimation, insufficient reaction, poor mechanical properties, etc., to improve mechanical properties, avoid insufficient reaction, and enhance mechanical properties Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

[0018] Specific implementation mode 1: This implementation mode records a method for preparing a self-healing polymer composite material, and the specific steps of the method are as follows:

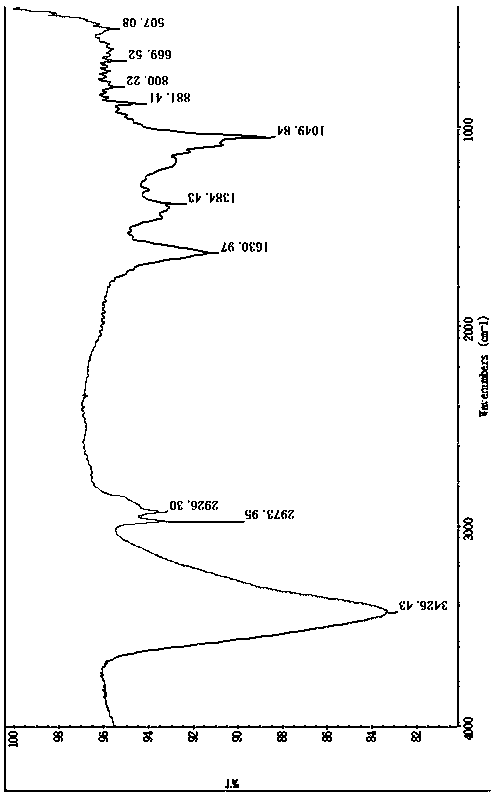

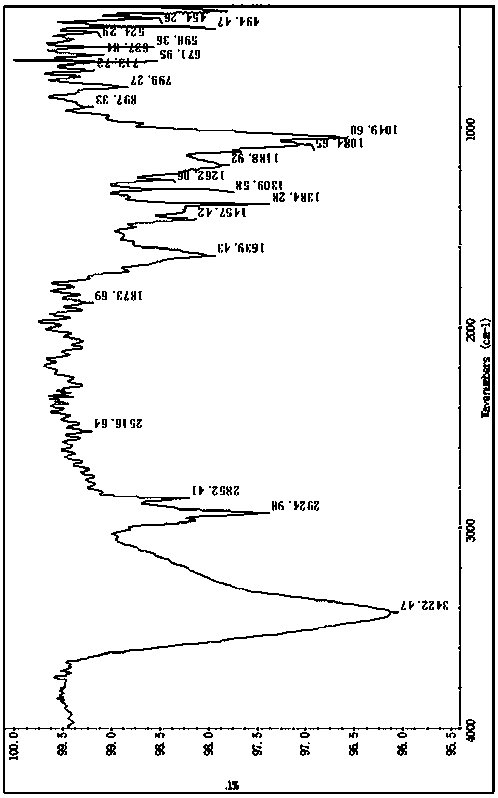

[0019] Step 1: Preparation of amidated carbon nanotubes: At room temperature, ultrasonically disperse 300 to 500 mg of ureidopropyltrimethoxysilane in a mixed solution of ethanol and water. The total volume of the solution after mixing is 250 mL. Among them, ethanol and water The volume ratio is 3:1, the ultrasonic time is 1 hour, and the ultrasonic power is 150W. It can be dispersed more uniformly by ultrasonic, and then 100~200mg of surface hydroxylated carbon nanotubes are added to the mixed solution obtained above. Heating in a water bath at a temperature of 70°C, followed by condensation and reflux to obtain surface amidated carbon nanotubes; by performing infrared testing on the reacted amidated carbon nanotubes, Table 1, figure 1 with figure 2 ,by comparison figure 2 and figu...

specific Embodiment approach 2

[0022] Embodiment 2: In the preparation method of a self-healing polymer composite material described in Embodiment 1, in step 1, the heating time in the water bath is 4 hours.

specific Embodiment approach 3

[0023] Embodiment 3: In the method for preparing a self-healing polymer composite material described in Embodiment 1, in step 1, the condensation and reflux time is 2 h, 4 h, 6 h or 8 h.

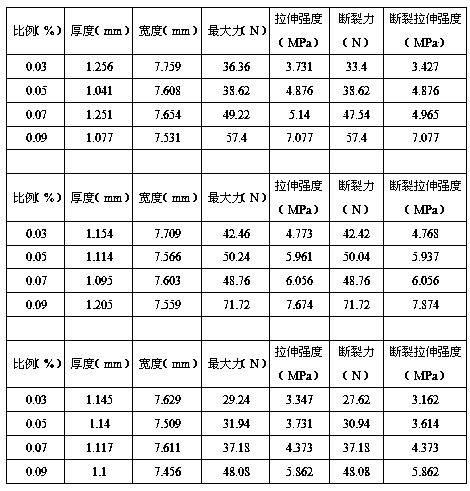

[0024] Table 1 Mechanical property test of amidated carbon nanotube self-healing polymer

[0025]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com