Rotary biofilm reactor

A biofilm reactor, rotary technology, applied in biological treatment devices, sustainable biological treatment, biological water/sewage treatment, etc., can solve the problem of membrane flux decline, reduce energy consumption, reduce aeration volume and aeration time and other issues, to achieve the effect of efficient handling

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

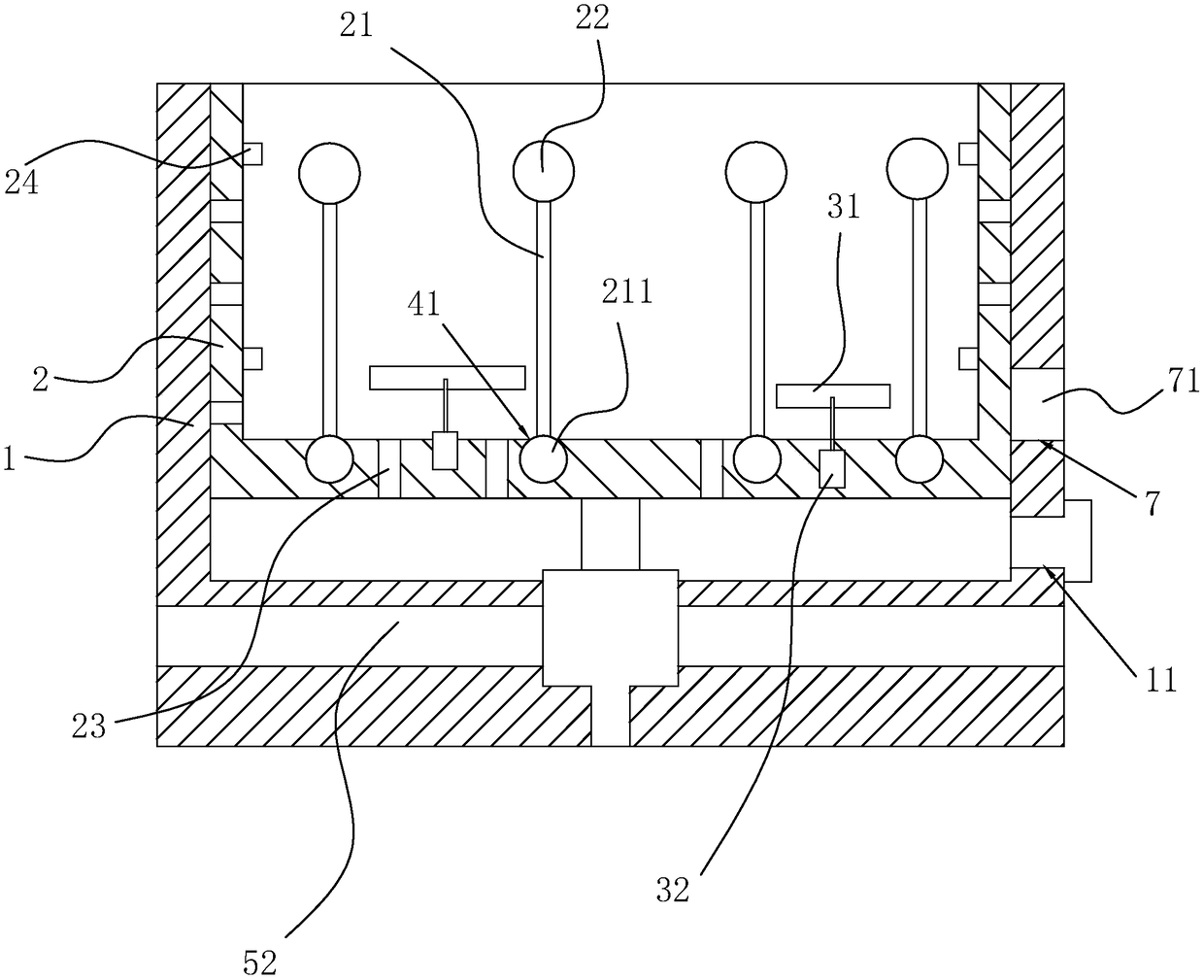

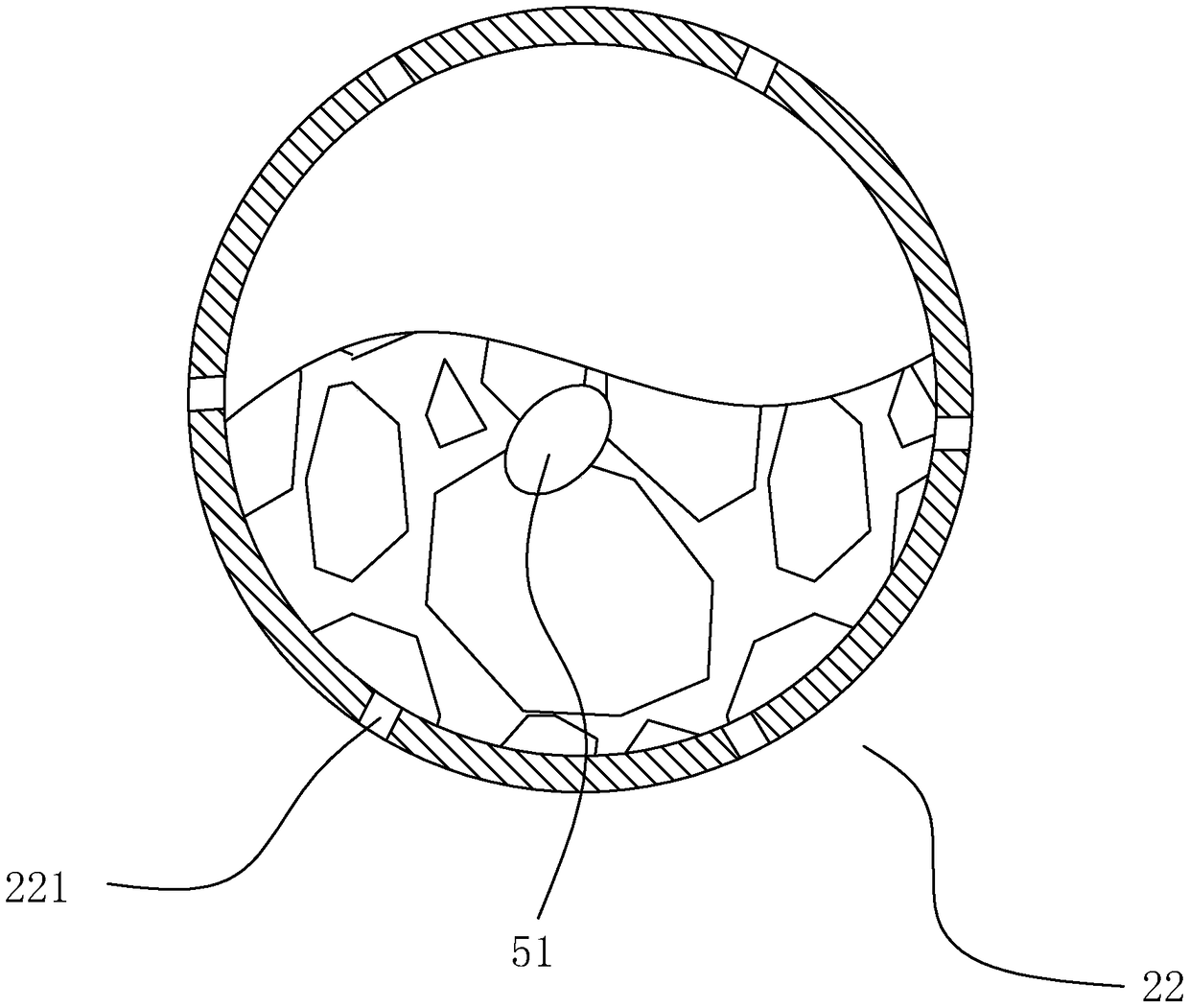

[0029] A rotary biofilm reactor, such as figure 1 As shown, it includes an outer frame 1 and a reaction chamber 2. The outer frame 1 and the reaction chamber 2 are nested with each other, and a lifting device is provided between the two. The reaction chamber 2 and the outer frame 1 can be separated by using the lifting device. The lifting device includes a groove 61 formed from the bottom of the outer frame 1 and a cylinder 62 arranged in the groove 61. The piston rod of the cylinder 62 is connected to the bottom of the reaction chamber 2, and a hole may be provided at the bottom of the groove 61 for the cylinder. 62 communicates with the outside world, but sealing measures need to be taken at the hole; some fixed rods 21 are arranged in the reaction chamber 2, and each fixed rod 21 is provided with a biological filler cage 22, and the reaction chamber 2 is provided with a number of holes penetrating through its thickness. The through hole 23 also includes a connection device ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com