Deposition chamber for improving gas distribution and MPCVD device

A gas distribution and deposition chamber technology, applied in gaseous chemical plating, metal material coating process, coating, etc., can solve problems such as uneven gas distribution, insufficient gas reaction, and affecting the reaction efficiency of chemical vapor deposition devices. Achieve the effect of improving utilization rate and simplifying structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

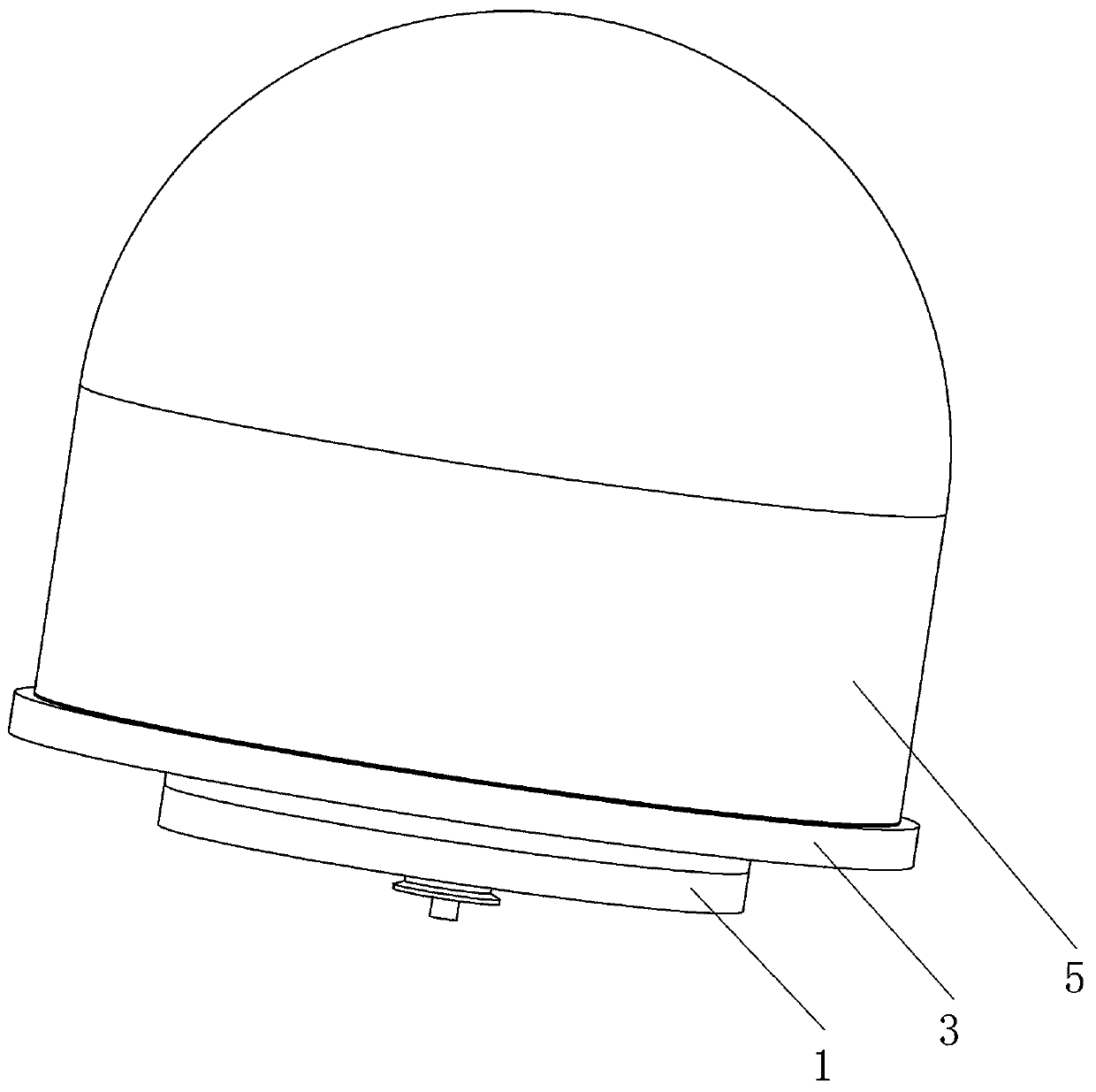

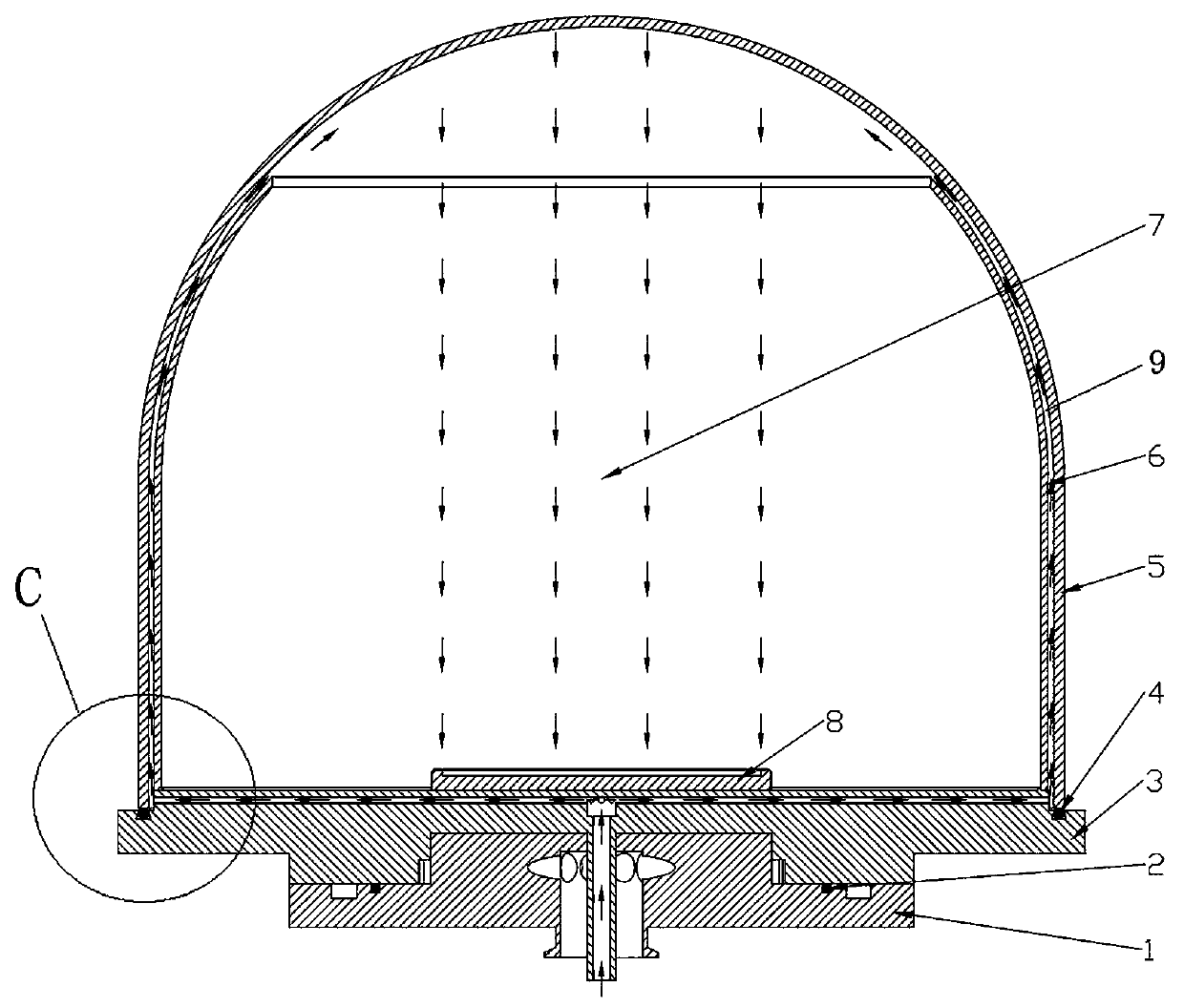

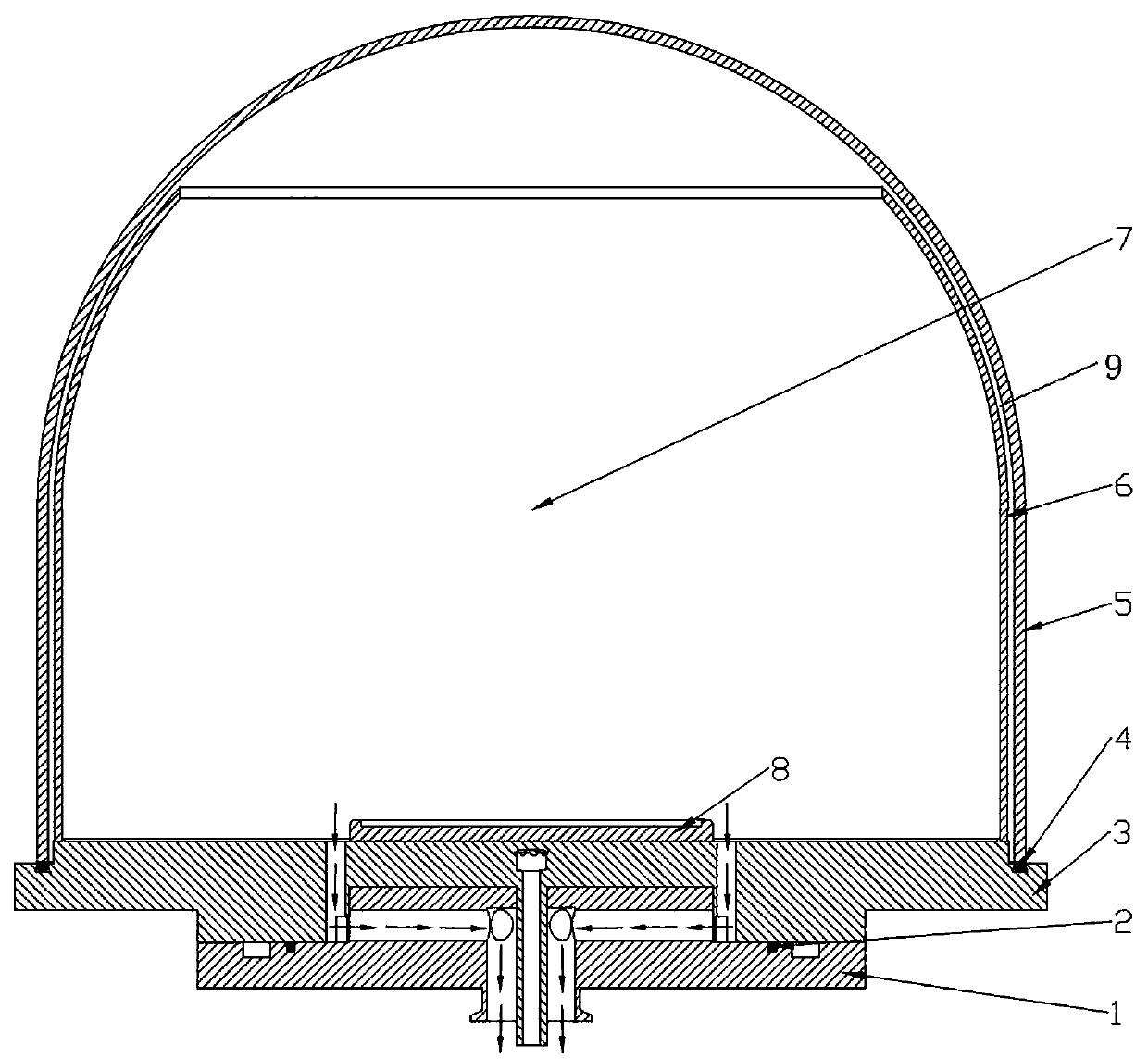

[0054] Embodiment 1 of the deposition chamber for improving gas distribution in the present invention, the deposition chamber in this embodiment is applied in a microwave plasma chemical vapor deposition device.

[0055] In order to facilitate the description of the structure and function of the deposition chamber, the structure of the microwave plasma chemical vapor deposition device is briefly introduced first. A microwave plasma chemical vapor deposition device, that is, an MPCVD device, includes a microwave power supply, a microwave generator, a circulator, a water load, a matcher, a mode converter, and a resonant cavity. A deposition chamber for improving gas distribution is arranged in the resonant cavity. Among them, the microwave generator is used to generate microwaves, which enter the reaction chamber of the deposition chamber after being converted by the mode converter, ionize the gas molecules in the reaction chamber to generate plasma, and react on the correspondin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com