Structural-insulation graphite separation equipment

A graphite and sorting technology, which is applied in classification, solid separation, chemical instruments and methods, etc., can solve the problems of short service life and poor mechanical strength, and achieve the effects of improving service life, simple manufacturing process and meeting the requirements of use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] The following describes the technical solution of the present invention in detail through a best embodiment in conjunction with the accompanying drawings, but the protection scope of the present invention is not limited to the embodiment.

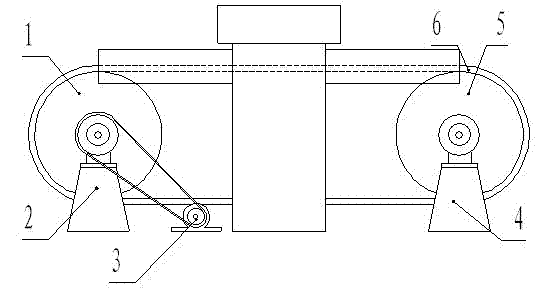

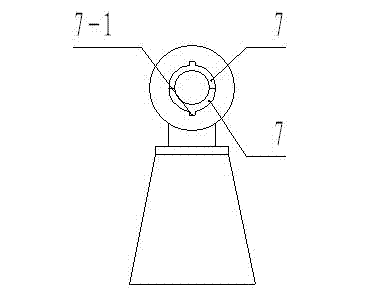

[0014] Such as figure 1 and figure 2 As shown, a graphite sorting equipment adopting structural insulation includes a driving wheel 1, a driving wheel bracket 2, a driving motor 3, a driven wheel bracket 4, a driven wheel 5 and a conveyor belt 6, and the driving wheel 1 is connected to the driving motor through a transmission belt. 3 connection, the driving wheel 1 is hinged with the driving wheel bracket 2, the driven wheel 5 is hinged with the driven wheel bracket 4, the driving wheel 1 and the driven wheel 5 are connected through the conveyor belt 6, and the shafts are installed on the driving wheel bracket and the driven wheel bracket respectively. Two ceramic bearing bushes 7 are arranged at the position of the ceramic bearing...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com