Switch reluctance motor

A technology of switched reluctance motors and motor rotors, which is applied in the direction of electric components, electrical components, electromechanical devices, etc., and can solve problems such as the greater influence of the degree of synchronization between the rotor and the main shaft, and achieve the effects of saving raw materials, reducing collisions, and improving accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

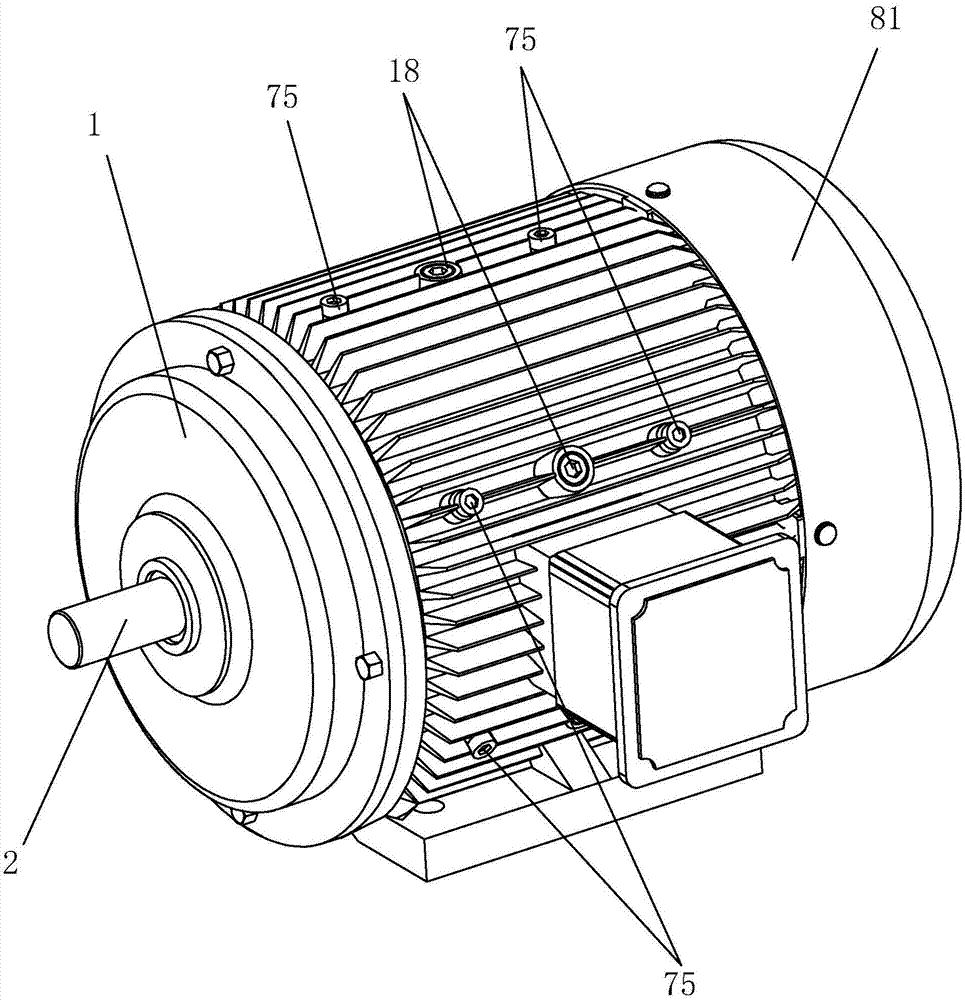

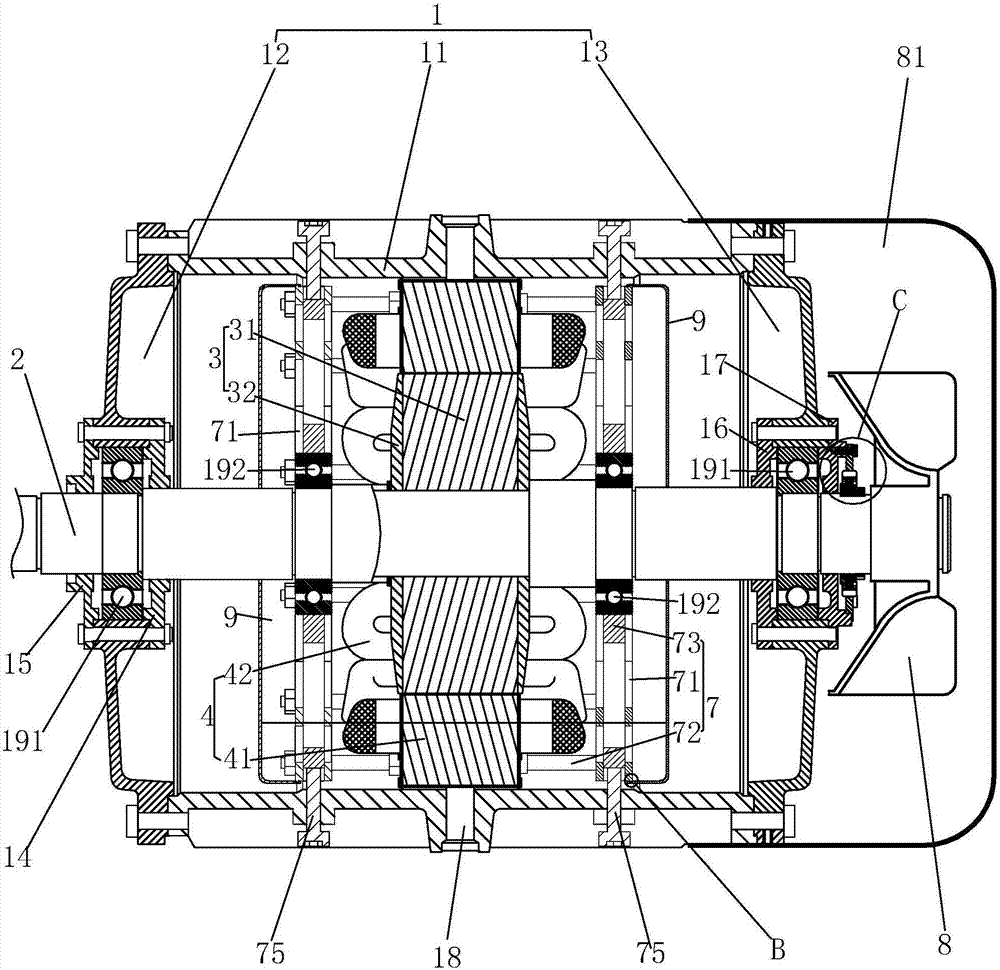

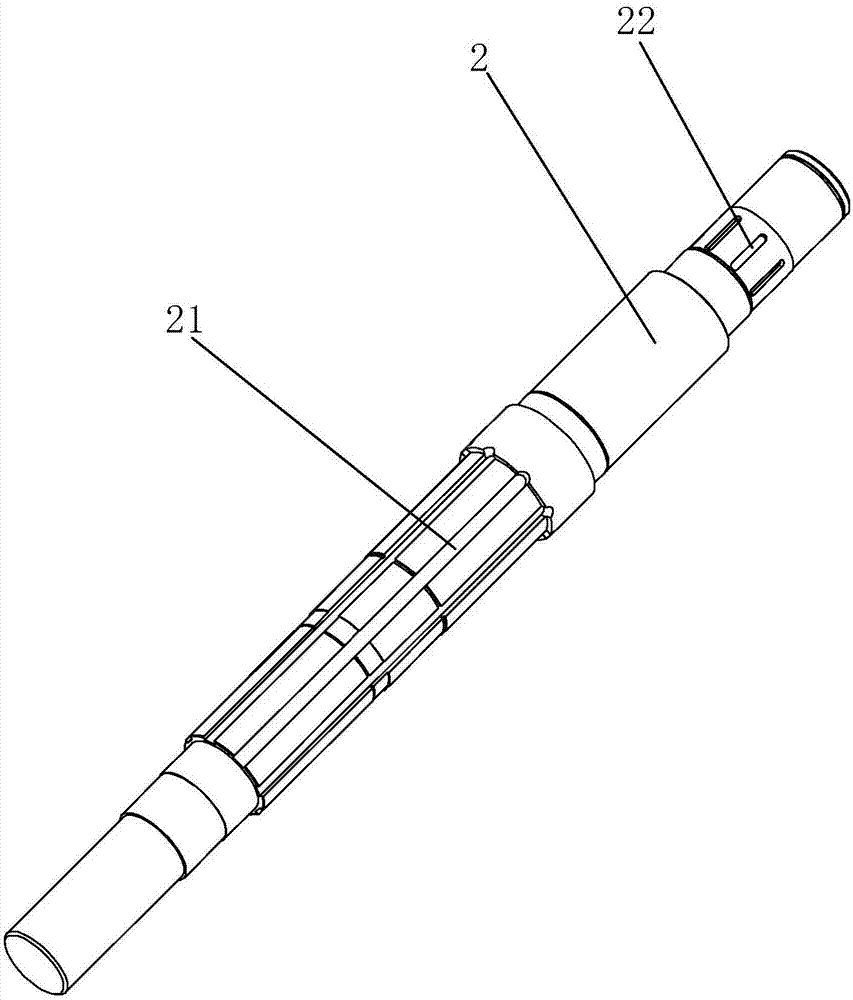

[0052] Embodiment 1: as figure 1 and figure 2 As shown, it includes a casing 1, a main shaft 2 rotatably connected to the casing 1, a motor rotor 3 fixed on the main shaft 2, a motor stator 4 fixed in the casing 1, and a reluctance type for detecting the position of the motor rotor 3. Rotary transformer 5, support frame 7 and soundproof cover 9.

[0053] The casing 1 includes a machine base 11 with two ends open, a front end cover 12 flanged to one end of the machine base 11 , and a rear end cover 13 flanged to the other end of the machine base 11 . The centers of the front end cover 12 and the rear end cover 13 respectively have bearing holes, and the first bearings 191 supporting the rotation of the main shaft 2 and located at both ends of the main shaft 2 are provided in the bearing holes.

[0054] The front end cover 12 is fixedly connected with a front bearing inner end cover 14 and a front bearing outer end cover 15 which lock the axial position of the first bearing 1...

Embodiment 2

[0077] Embodiment 2: The difference with Embodiment 1 is that, as Figure 19 As shown, each rotor key table 313 is respectively facing the gap between the salient poles 312 of two adjacent motor rotors; that is, the mid-vertical line of the rotor key table 313 close to the shaft center end surface of the shaft hole 314 is located between two adjacent motor rotors. The distance between the salient poles 312 and to the salient poles 312 of the two motor rotors is equal.

Embodiment 3

[0078] Embodiment 3: The difference with Embodiment 1 is that, as Figure 20 As shown, the resolver key table 522 is aligned with the rotor salient pole 312 , that is, the second key slot 62 is aligned with the rotor key slot 21 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com