Online scale removal method for smoke gas turbine of catalytic cracking unit

A technology for catalytic cracking devices and hoods, applied to cleaning methods and appliances, chemical instruments and methods, and cleaning methods using gas flow, etc., can solve the problems of low cleaning efficiency, improve cleaning efficiency, reduce vibration, The effect of reducing losses

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

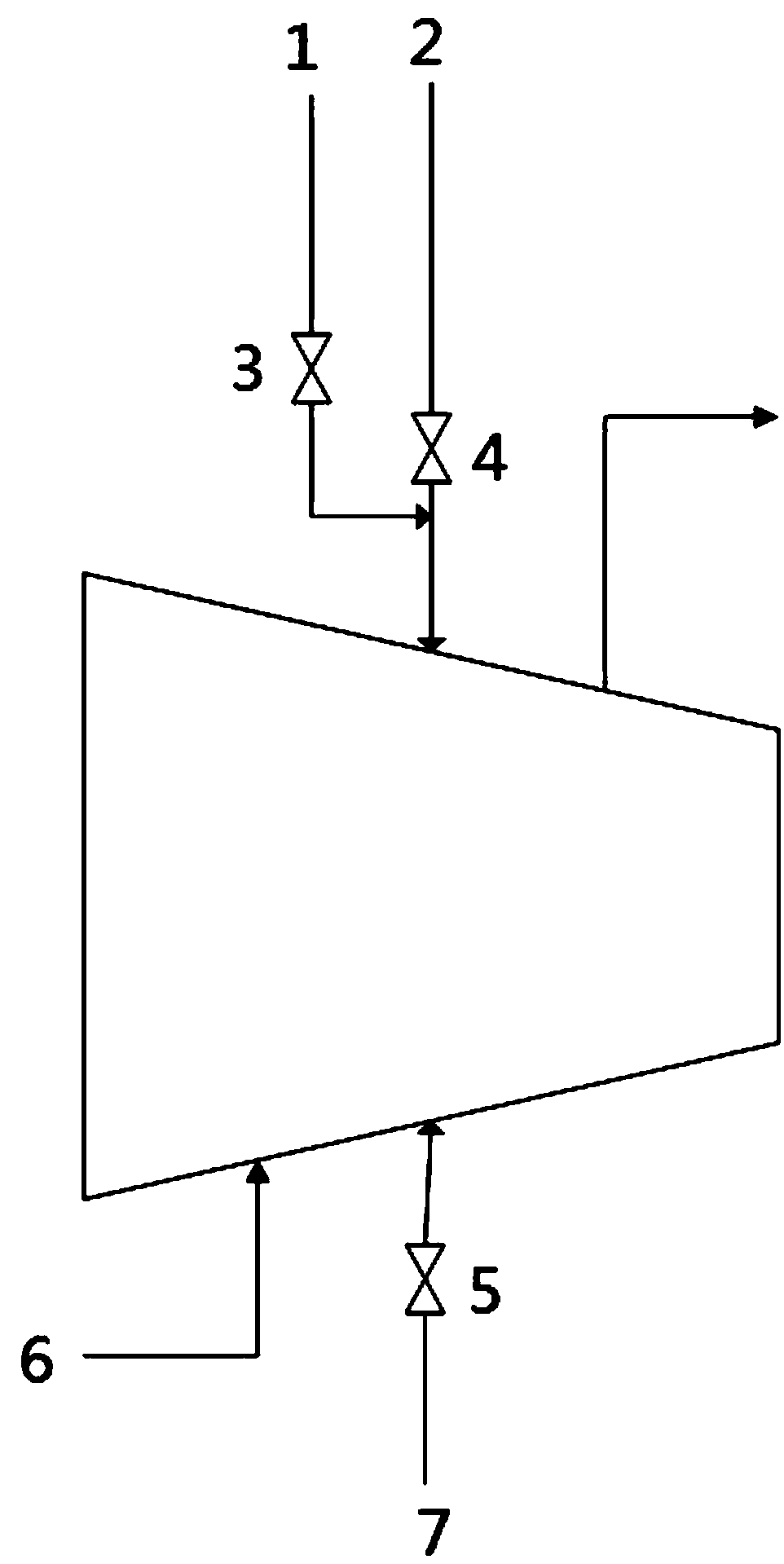

[0032] A kind of method for online scale cleaning of flue gas machine of catalytic cracking unit, such as figure 1 As shown, the online descaling technology for hoods invented adopts the method of "segmented cooling and intermittent flushing". Sweep (200-120°C). In order to prevent damage to the impeller, the maximum speed of the hood in the hot state is controlled within 1000rpm during the descaling process. At other times, the hood always starts automatic cranking, and the cranking speed is 73rpm. The specific process is as follows:

[0033] 1. Unit switching

[0034] The main fan-hood fan unit is switched to the standby machine, the main fan-hood fan system is shut down, and the electric barring is started. The gate valve and butterfly valve at the inlet of the hood are closed, the water seal tank is filled with water, the vent valve at the outlet of the hood is fully opened, the sealing air and sealing steam are put into use normally, the lubricating oil pump is operati...

Embodiment 2

[0053] According to the conditions and steps described in Example 1, the method of the present invention is applied to the online descaling of a hood of an FCC device. The design parameters of a smoke machine are the inlet temperature of 670°C, the inlet pressure of 0.24MPa(g), and the flow rate of 3050m 3 / min. The vibration value of the hood shell has increased. The maximum vibration of the machine body reaches 6.5mm / s, and continues to fluctuate. After cleaning the scale online according to the above method, after the unit is restarted, the vibration speed of the hood shell reaches 1.6mm / s, the shaft vibration is 25.5um, and the hood operates normally.

Embodiment 3

[0055] According to the conditions and steps described in Example 1, the method of the present invention is applied to the online descaling of a certain FCC device B hood. The design parameters of a certain hood are intake temperature 670°C, intake pressure 0.25MPa(g), Flow 2500m 3 / min. The vibration of the rotor shaft rose to above 90μm, and the vibration speed of the bearing box shell rose to above 12mm / s. After analysis, it was caused by the fouling of the hood. The hood was cleaned online according to the above-mentioned technical method. After the flue gas is put into operation, the vibration of the front pad shaft is 25 μm, the rear pad shaft is 29 μm, the vibration speed of the bearing box on site is 0.9 mm / s, and the range hood operates normally.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com