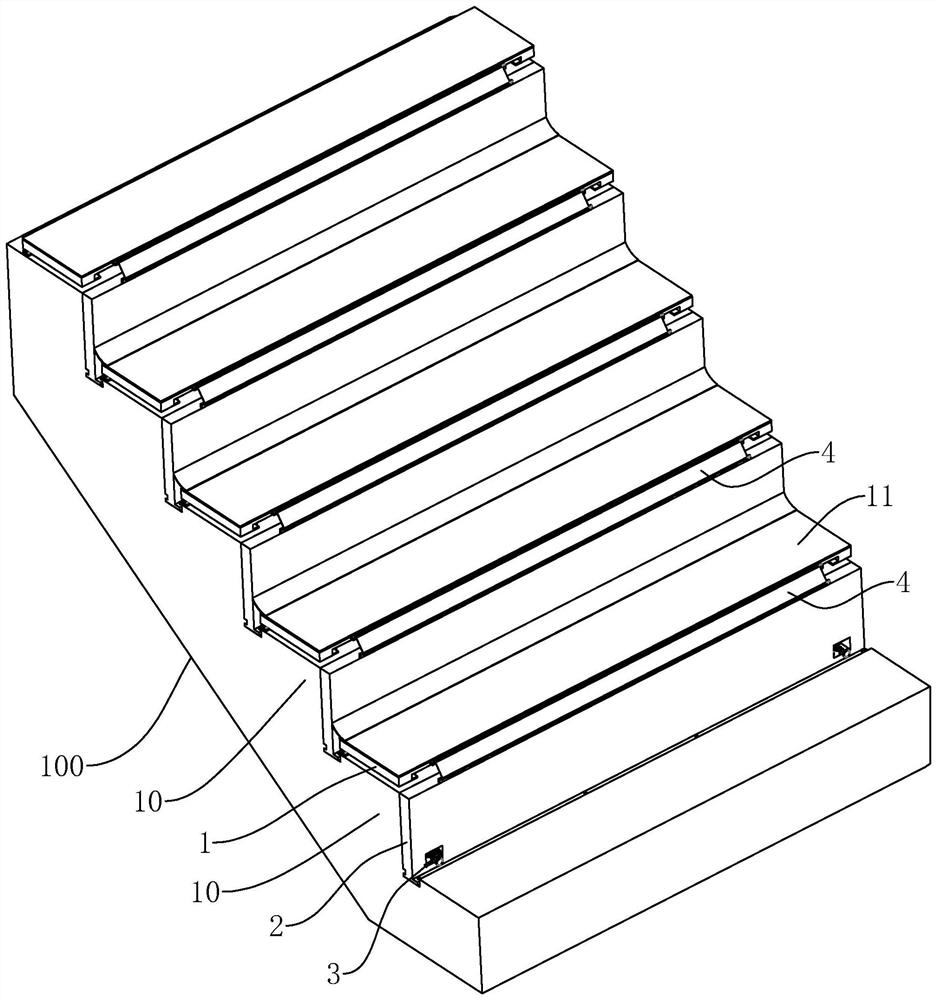

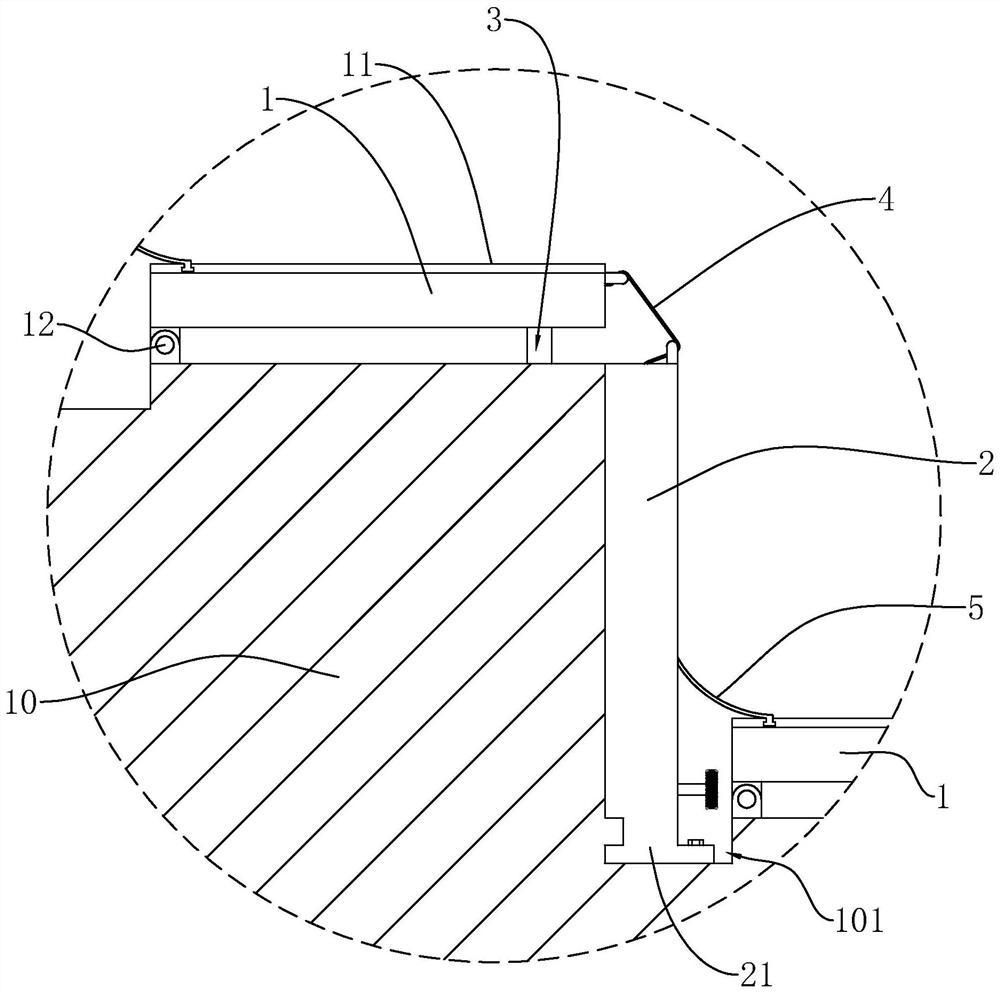

Prefabricated assembly type stairway

A prefabricated assembly and staircase technology, applied in the direction of stairs, pedals, etc., can solve the problems of low safety factor, difficulty in keeping the level of the horizontal platform of the stairs, and discomfort when going up and down stairs, so as to improve the sense of dynamic balance, reduce dust accumulation, Reduce the effect of excessive gear fit clearance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 2

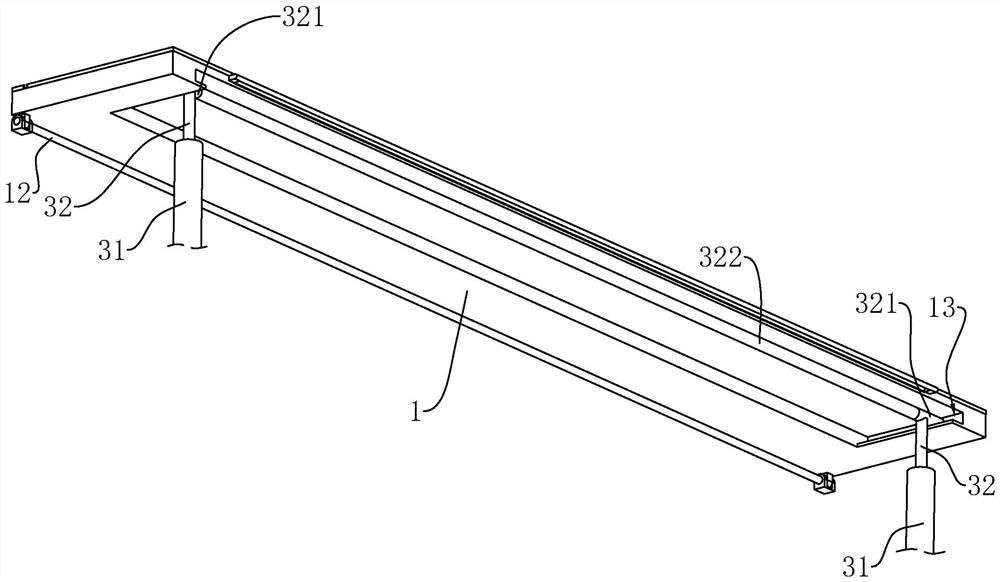

[0053] Embodiment 2, make the following setting on the basis of embodiment 1, such as Figure 7 As shown, a bracket 6 is provided between the free side of the pedal 1 and the near side of the vertical plate 2, the bracket 6 is fixedly connected with the upper side of the vertical plate 2, and can be fixed by welding or nailing, and the bracket 6 is fixed There are a first support roller 61 and a second support roller 62, the first support roller 61 and the second support roller 62 are arranged along the length direction of the step 10, and the roller surfaces of the first support roller 61 and the second support roller 62 all abut against each other on the inner surface of the rubber belt 4 to support the rubber belt 4 so that it has a certain rigidity and is convenient for supporting people's feet.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com