Commutator, motor and cutter

A commutator and cutting tool technology, which is applied in the field of commutators, can solve the problems of short tool life, high economic cost, and lack of mass production, so as to prolong life, reduce economic cost, and have mass production. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

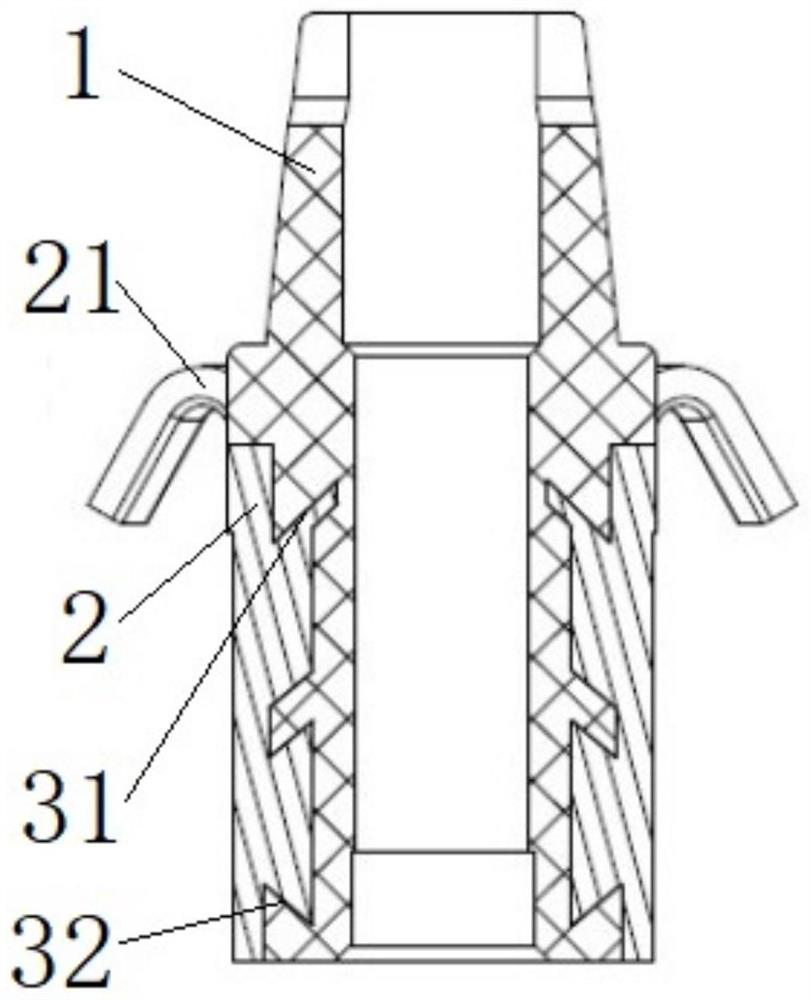

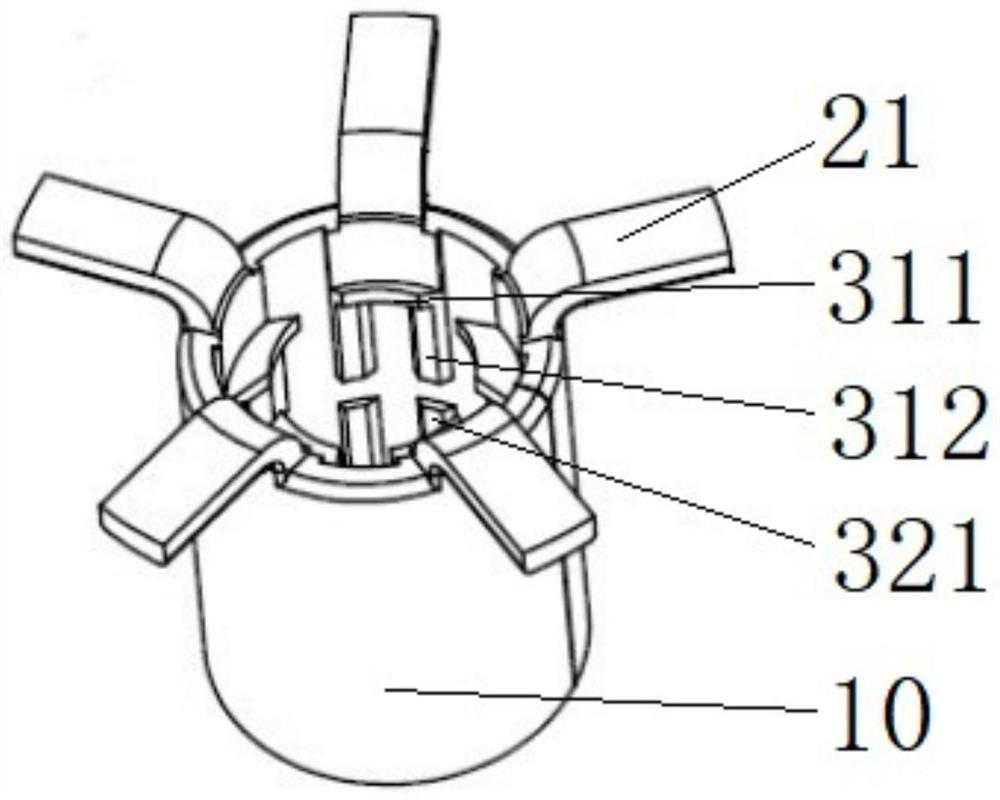

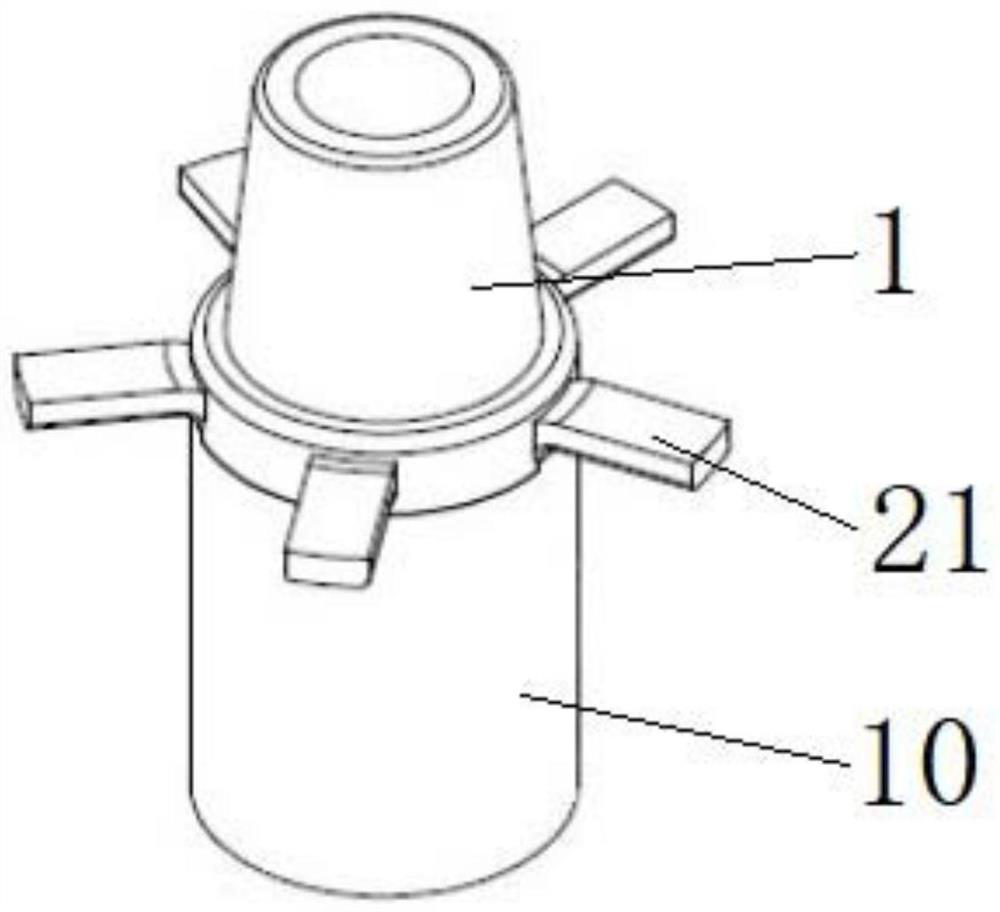

[0041] This embodiment provides as Figure 1 to Figure 4 A commutator shown includes an insulating base 1 and a commutator segment 2 . The commutator segment 2 is arranged on the periphery of the insulating base 1, and the commutating segment 2 has a plurality of K-shaped inner hooks for connecting to the insulating base 1, and the diameter of the commutator is greater than or equal to 7.8 mm and less than 8.8 mm. Specifically, the commutator segment 2 is made of copper or other materials. It should be noted that the diameter of the commutator refers to the diameter of the outer wall surface of the enclosed commutator segment 2, where figure 1 The outer wall surface of the middle commutator piece 2 is gradually shrunk in the direction away from the wire hook 21 of the commutator piece 2. At this time, the diameter of the commutator means that the outer wall surface of the commutator piece 2 is close to the wire hook 21 diameter of the end.

[0042] Such as figure 1 with ...

Embodiment 2

[0047] This embodiment provides a motor, which includes the commutator of Embodiment 1. It should be noted that the commutator in Embodiment 1 is suitable for motors with low noise, long life and high safety requirements.

Embodiment 3

[0049] This embodiment provides as Figure 5 with Image 6 A cutter is shown, which includes a cutter bar 4 , a plurality of first coulter teeth 52 , a plurality of second coulter teeth 62 , a guide head 71 , a first coulter 51 , a second coulter 61 and a cutter bar sleeve 8 . Such as Figure 5 with Image 6 As shown, some first coulter teeth 52 are arranged on the knife bar 4 along the circumferential direction; several second coulter teeth 62 are arranged on the knife bar 4 along the circumferential direction, and the first coulter teeth 52 are arranged on the second coulter teeth 62 is close to the head side of the knife bar 4, and the inner hook of the commutator is processed by the first coulter tooth 52 and the second coulter tooth 62.

[0050] By machining the commutator in Embodiment 1, the sum of the numbers of the first coulter teeth 52 and the second coulter teeth 62 is equal to the number of gaps between the K-shaped inner hooks. That is, during processing, the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com