Combined steel pipe straightening roller and straightening device thereof

A straightening and component technology, applied in the field of steel pipe straightening, can solve the problems of fixed range and inability to adjust, and achieve the effect of expanding the range, easy assembly, and convenient individual processing.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

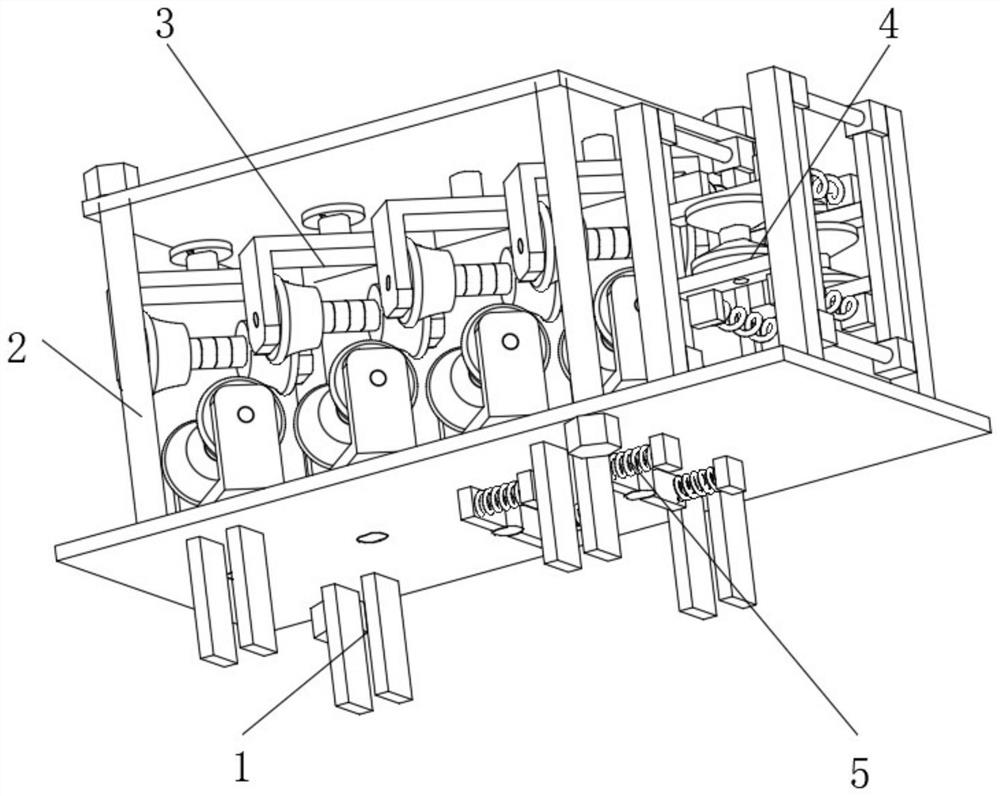

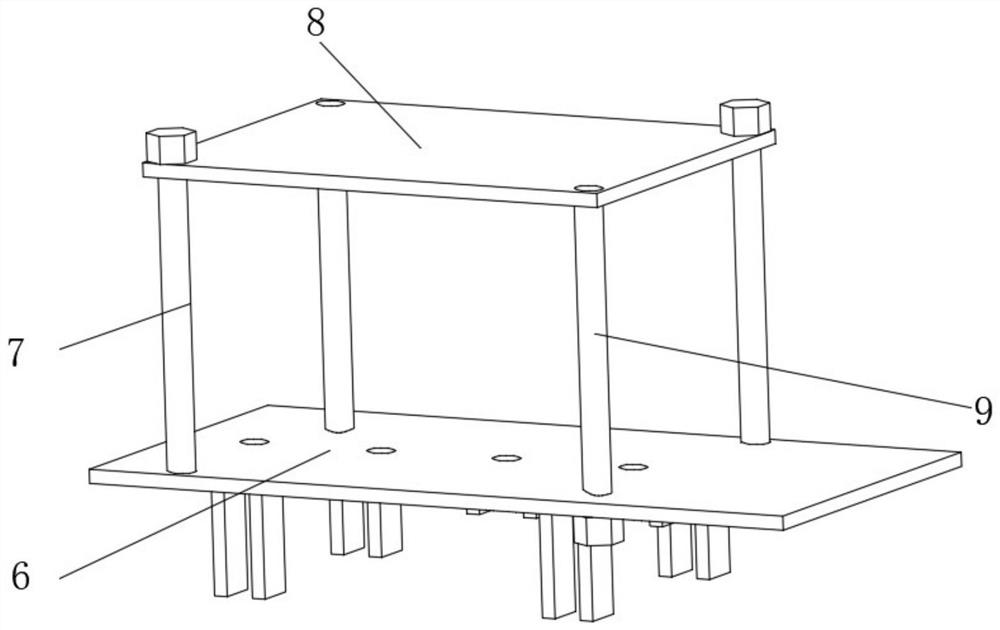

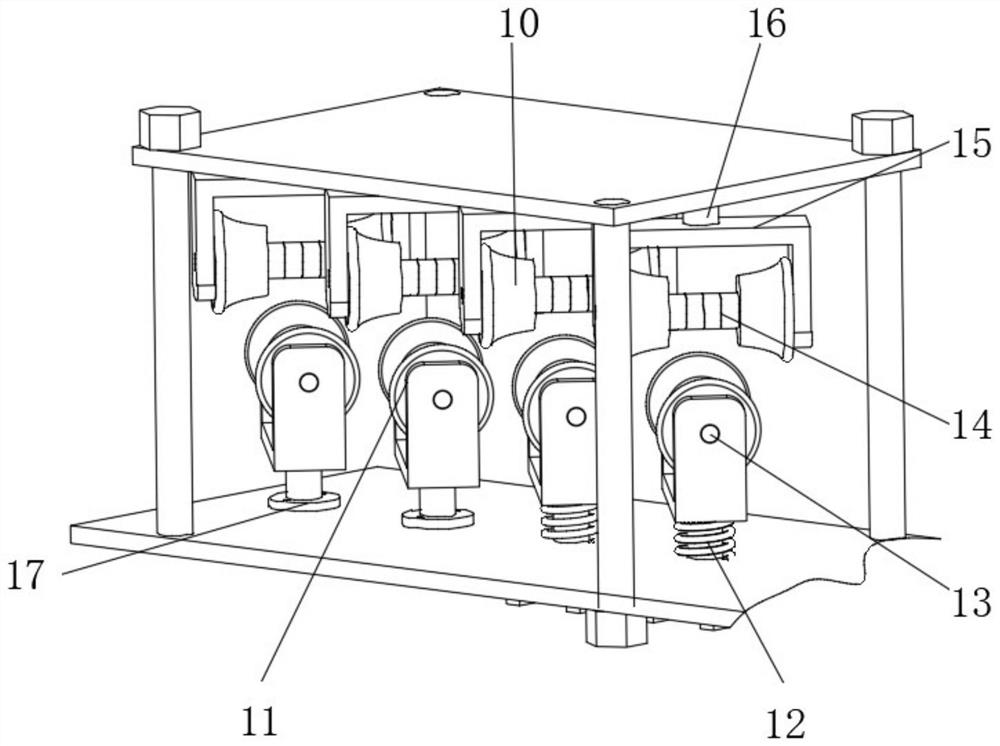

[0036] Straightening devices such as figure 1 , 2As shown, it includes an adjustable frame structure 2 fixed to the ground through the legs 1. The adjustable frame structure 2 includes a base 6 and a top plate 8. The diagonal inner wall of the top plate 8 is threaded with a first screw 7. The other diagonal inner wall of the top plate 8 is rotatably connected with a second screw 9, the bottom inner wall of the first screw 7 is in contact with the top exterior of the base 6, and the other side outer wall of the second screw 9 is threadedly connected. On the inner wall of the base 6, the top of the base 6 and the bottom outer wall of the top plate 8 are provided with a straightening mechanism 3, the top outer wall of the base 6 is provided with a conveying mechanism 4, and the bottom outer wall of the base 6 is provided with a front-end limiting mechanism 5. In this embodiment, put the bending plane of the steel pipe parallel to the vertical plane into the conveying mechanism 4...

Embodiment 2

[0042] Combined steel pipe straightening rollers, such as Image 6 , 7 As shown, it is the straightening roller 14 in Embodiment 1, which specifically includes a first roll block 30, a second roll block 31 and a rotating shaft 34, and the surfaces of the first roll block 30 and the second roll block 31 are all processed with Hyperboloid surface, the outer wall of the opposite side of the first roller block 30 and the second roller block 31 is provided with an adjusting pad 35, and the inner wall of the first roller block 30 and the second roller block 31 is provided with a first keyway 36, The inner wall of the adjusting spacer 35 is provided with a second keyway 37, and the rotating shaft 34 cooperates with the first keyway 36 and the second keyway 37 through the protrusion 33 provided thereon. The first roller block 30, the second The inner walls of the roller block 31 and the adjusting cushion block 35 are all provided with through holes, and the inner walls of the through...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com