A bearing ring processing lathe

A technology of bearing rings and lathes, applied in metal processing, metal processing equipment, metal processing machinery parts, etc., can solve the problems of reducing production efficiency and increasing the workload of operators, so as to improve production efficiency, facilitate cleaning and collection, Avoid out-of-conduction effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0036] The present invention will be described in further detail below in conjunction with the accompanying drawings.

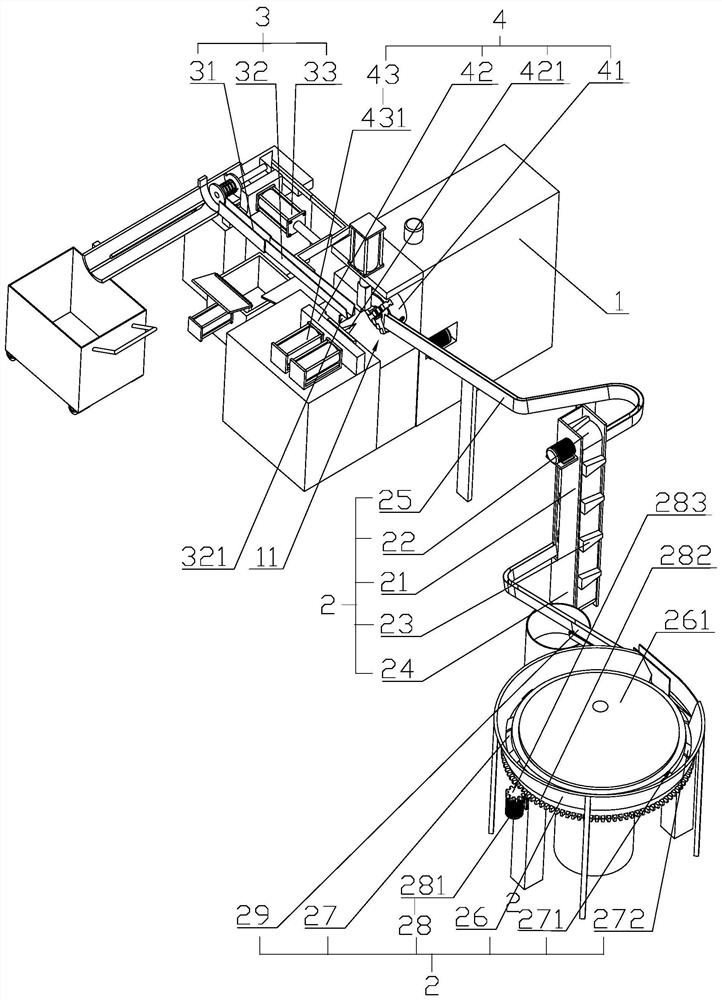

[0037] refer to figure 1 , figure 2 , is a bearing ring processing lathe disclosed in the present invention, including a machine body 1, and also includes a feeding mechanism 2, a cutting mechanism 4, and a material discharging mechanism 3 sequentially arranged on the body 1 along the bearing ring transmission direction. The feeding mechanism 2 is used to arrange the scattered bearing rings in an orderly manner and send them one by one into the cutting mechanism 4 for cutting processing, and then send the processed bearing rings away from the processing position through the discharging mechanism 3 for sorting and collecting.

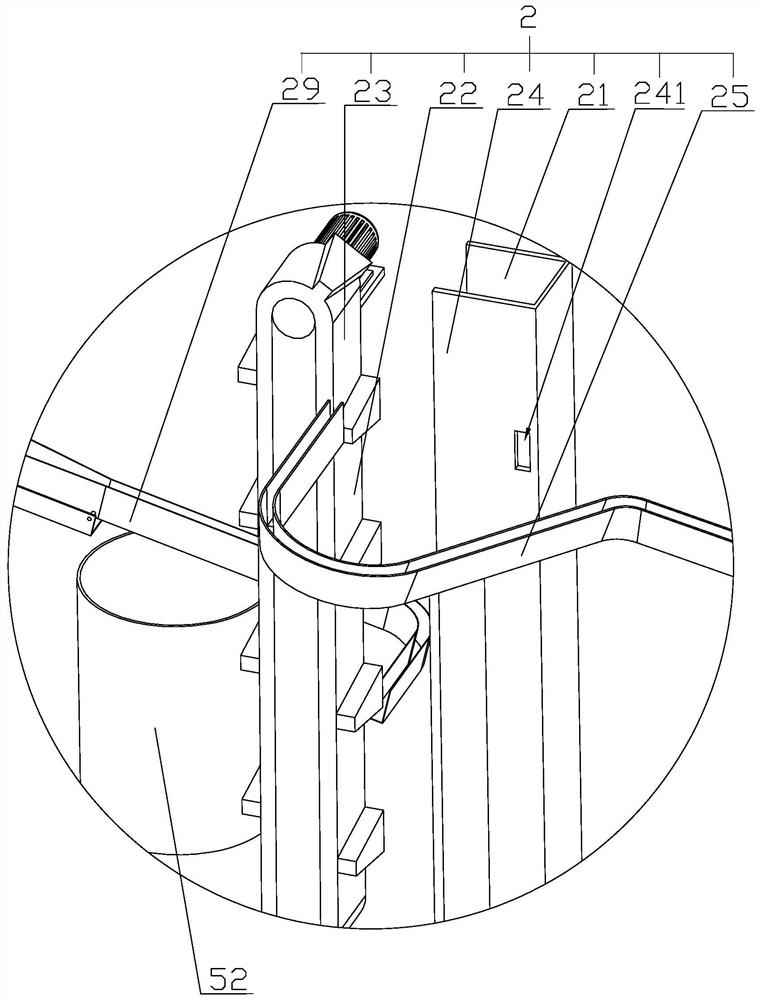

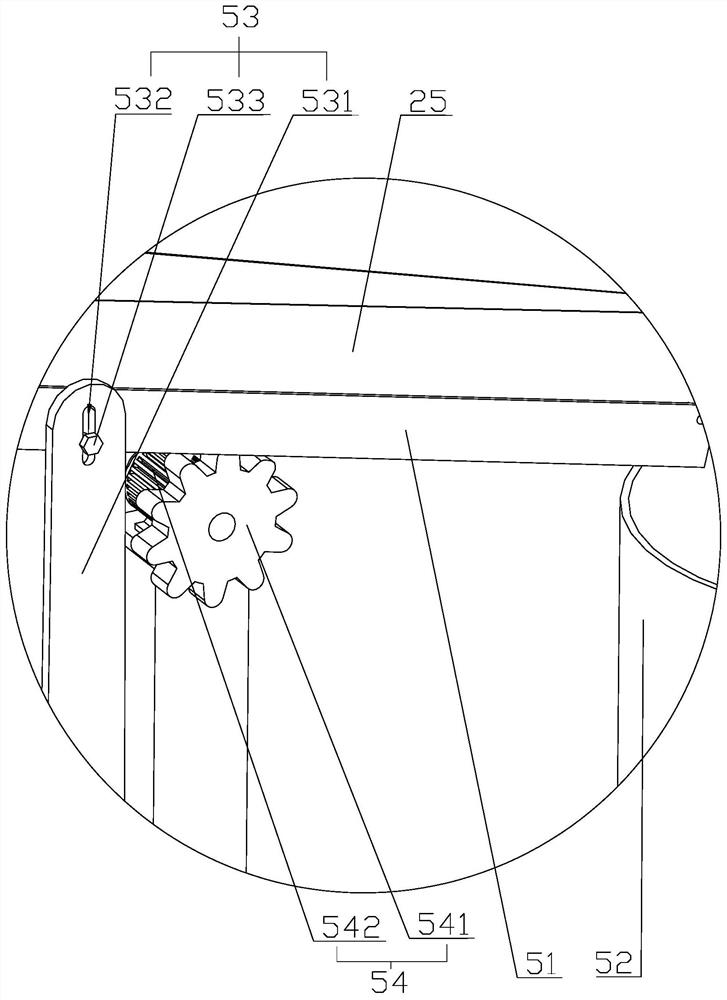

[0038] The feeding mechanism 2 includes a screening basin 26, a discharge plate 261 arranged on the screening basin 26, a booster ring 27 distributed along the circumferential direction of the discharge plate 261 and connected in rota...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com