Veneering process suitable for PUR hot melt adhesives

A hot-melt adhesive and veneer technology, which is used in the direction of manufacturing tools, wood processing appliances, and the joining of wooden veneers to reduce the curing time, reduce the temperature of the workshop, and avoid rebound.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

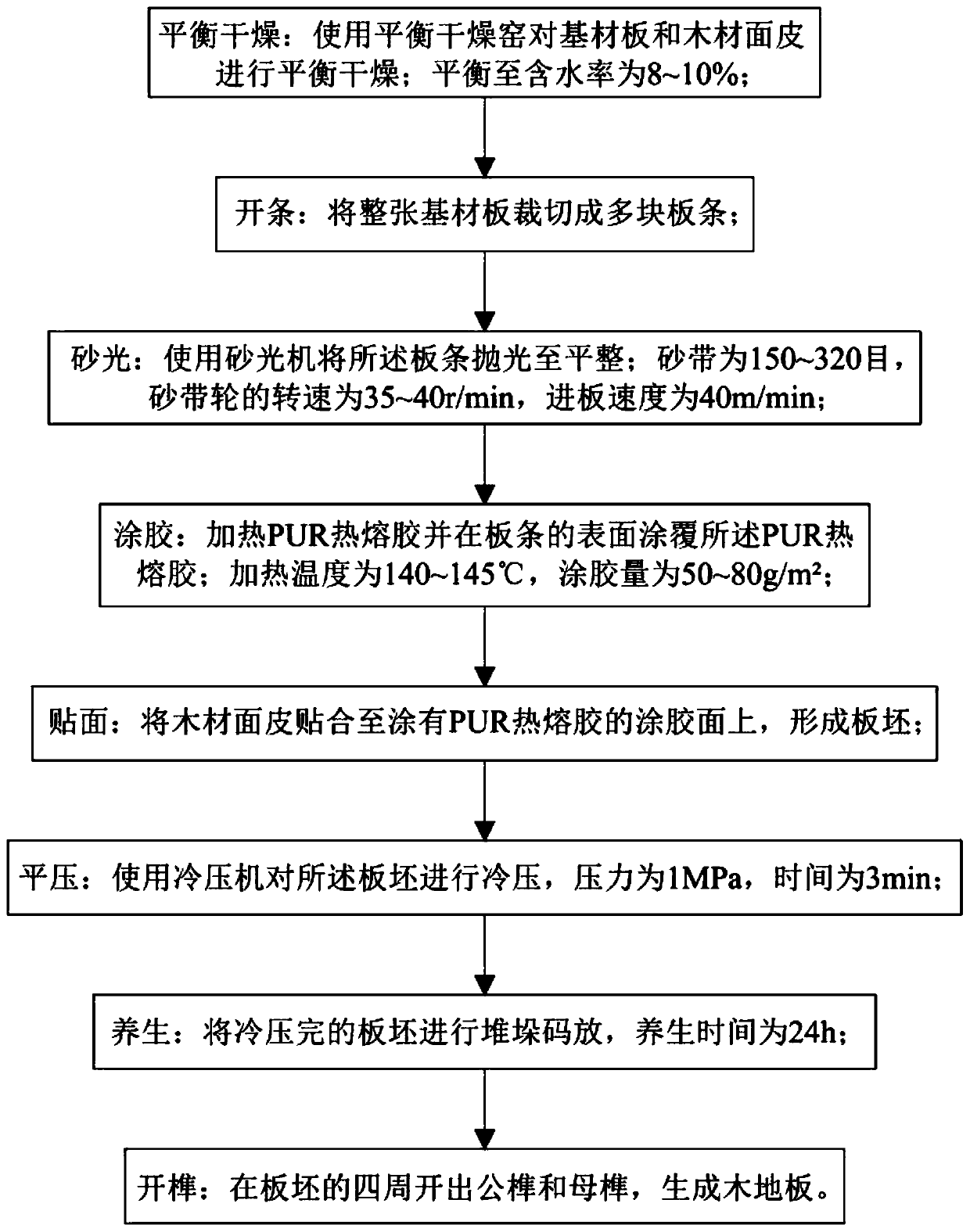

Method used

Image

Examples

Embodiment 1

[0038] Balanced drying: use a balance drying kiln to carry out balanced drying on the substrate board and the wood skin, and balance to a moisture content of 8%; after balanced drying, the moisture content of the substrate board and the wood skin is the same;

[0039] Cut strips: Cut the entire substrate board (1235mm×1235mm) into multiple strips (1235mm×175mm);

[0040] Sanding: use a polishing machine to polish the slats until smooth; the abrasive belt is 320 mesh, the rotational speed of the abrasive belt wheel is 40r / min, and the plate feeding speed is 40m / min;

[0041] Glue coating: heat the PUR hot melt adhesive and coat the PUR hot melt adhesive on the surface of the slat; the heating temperature is 140°C, and the glue coating amount is 50g / m 2 ;

[0042] Veneer: Align the wood skin (1235mm×175mm×0.6mm) with the slats, and attach the wood skin to the glued surface coated with PUR hot melt adhesive to form a slab;

[0043] Flat pressing: use a row of 6 small cold press...

Embodiment 2

[0047] Balanced drying: use a balance drying kiln to carry out balanced drying on the substrate board and wood skin, and balance to a moisture content of 9%; after balanced drying, the moisture content of the substrate board and the wood skin is the same;

[0048] Cut strips: Cut the entire substrate board (1235mm×1235mm) into multiple strips (1235mm×175mm);

[0049] Sanding: use a polishing machine to polish the slats until smooth; the abrasive belt is 250 mesh, the rotational speed of the abrasive belt wheel is 37r / min, and the plate feeding speed is 40m / min;

[0050] Glue coating: heat the PUR hot melt adhesive and coat the PUR hot melt adhesive on the surface of the slats; the heating temperature is 143°C, and the glue coating amount is 65g / m 2 ;

[0051] Veneer: Align the wood skin (1235mm×175mm×2.0mm) with the slats, and attach the wood skin to the glued surface coated with PUR hot melt adhesive to form a slab;

[0052] Flat pressing: use a row of 7 small cold presses ...

Embodiment 3

[0056] Balanced drying: use a balance drying kiln to carry out balanced drying on the substrate board and wood skin, and balance to a moisture content of 10%; after balanced drying, the moisture content of the substrate board and the wood skin is the same;

[0057] Cut strips: Cut the entire substrate board (1235mm×1235mm) into multiple strips (1235mm×175mm);

[0058] Sanding: use a polishing machine to polish the slats until smooth; the abrasive belt is 150 mesh, the rotational speed of the abrasive belt wheel is 35r / min, and the plate feeding speed is 40m / min;

[0059] Glue coating: heat the PUR hot melt adhesive and coat the PUR hot melt adhesive on the surface of the slats; the heating temperature is 145°C, and the glue coating amount is 80g / m 2 ;

[0060] Veneer: Align the wood skin (1235mm×175mm×4.0mm) with the slats, and attach the wood skin to the glued surface coated with PUR hot melt adhesive to form a slab;

[0061] Flat pressing: use a row of 8 small cold presses...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com