Installation structure of wall surface soft roll and construction method for installing wall surface soft roll

A technology for installing structures and soft packs, which is applied in building construction, covering/lining, construction, etc., can solve the problems of fabric wrinkles and fabric springback, and achieve the advantages of avoiding springback, low proficiency, and simple and easy-to-operate production methods Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

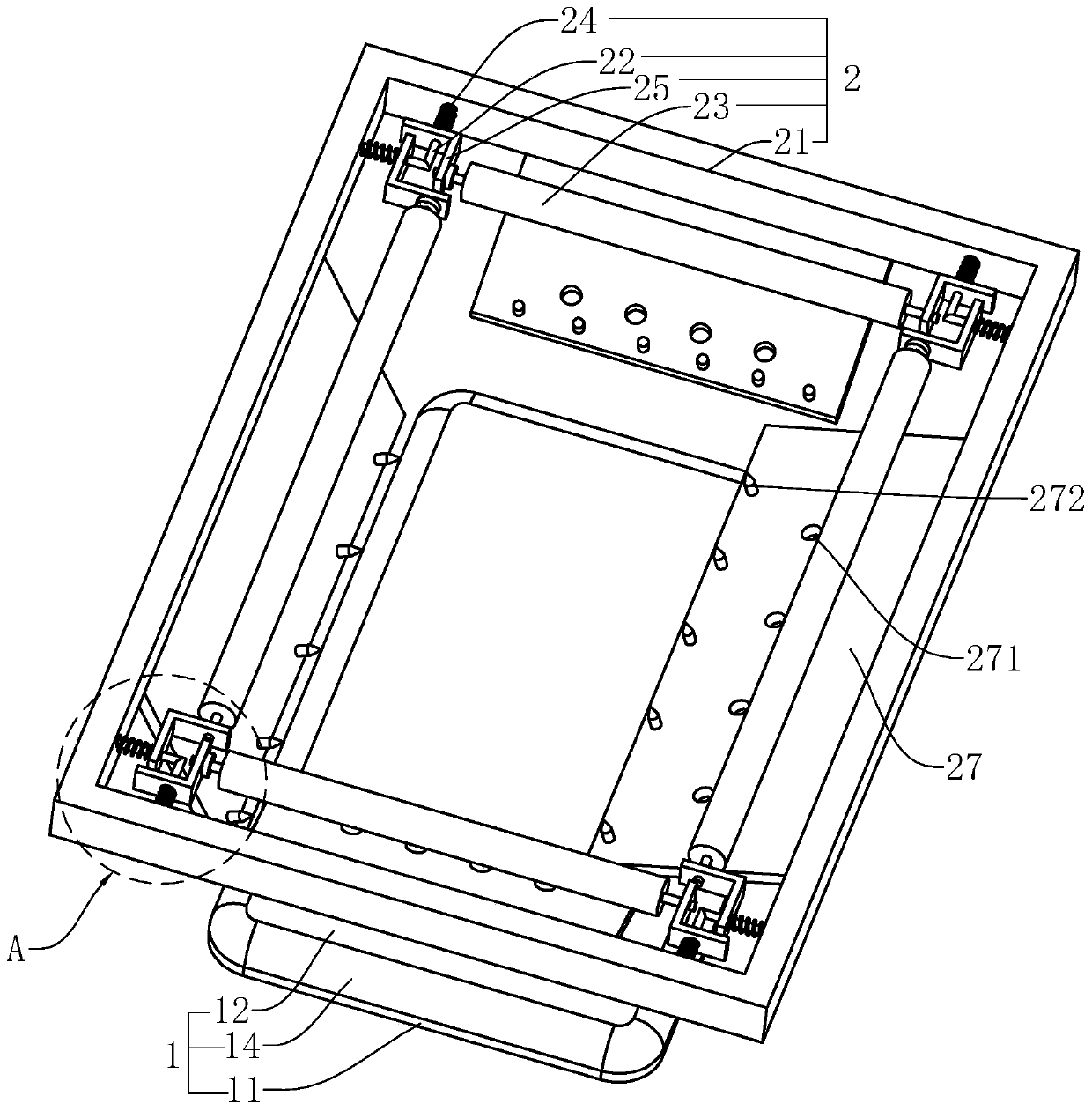

[0034] Such as figure 1 As shown, this embodiment introduces an installation structure of a soft wall covering, including a soft covering board 1 and an auxiliary tool 2 , and the effect of quickly installing the soft covering board 1 can be achieved by using the auxiliary tool 2 .

[0035] Such as figure 1 As shown, the soft clad board 1 includes a base plate 11, a filling layer 12 made of soft material, an elastic fabric and an edge banding strip 14, the edge banding strip 14 and the filling layer 12 are glued to one side of the base plate 11, and the edge banding The strip 14 is fixed on the periphery of the bottom plate, the filling layer 12 is located inside the frame surrounded by the edge sealing strip 14 , and the fabric wraps the filling layer 12 and the edge sealing strip 14 on the bottom plate 11 . The edge banding 14 is a hard material, such as wood, and the upper side and the outer side of the edge banding 14 are curved surfaces, so that the fabric is easy to fla...

Embodiment 2

[0043] This embodiment introduces a construction method for installing a wall soft bag, including steps S1-S3.

[0044] S1. Fix the vertical and horizontal keels on the wall, and then fix the liner on the outside of the keel;

[0045] S2. Making soft cladding board 1:

[0046] S21, first use the edge strip 14 to fix the periphery of the outer surface of the bottom plate 11, then stick the filling layer 12 to the outside of the bottom plate 11, and then cover the outside of the filling layer 12 with the fabric;

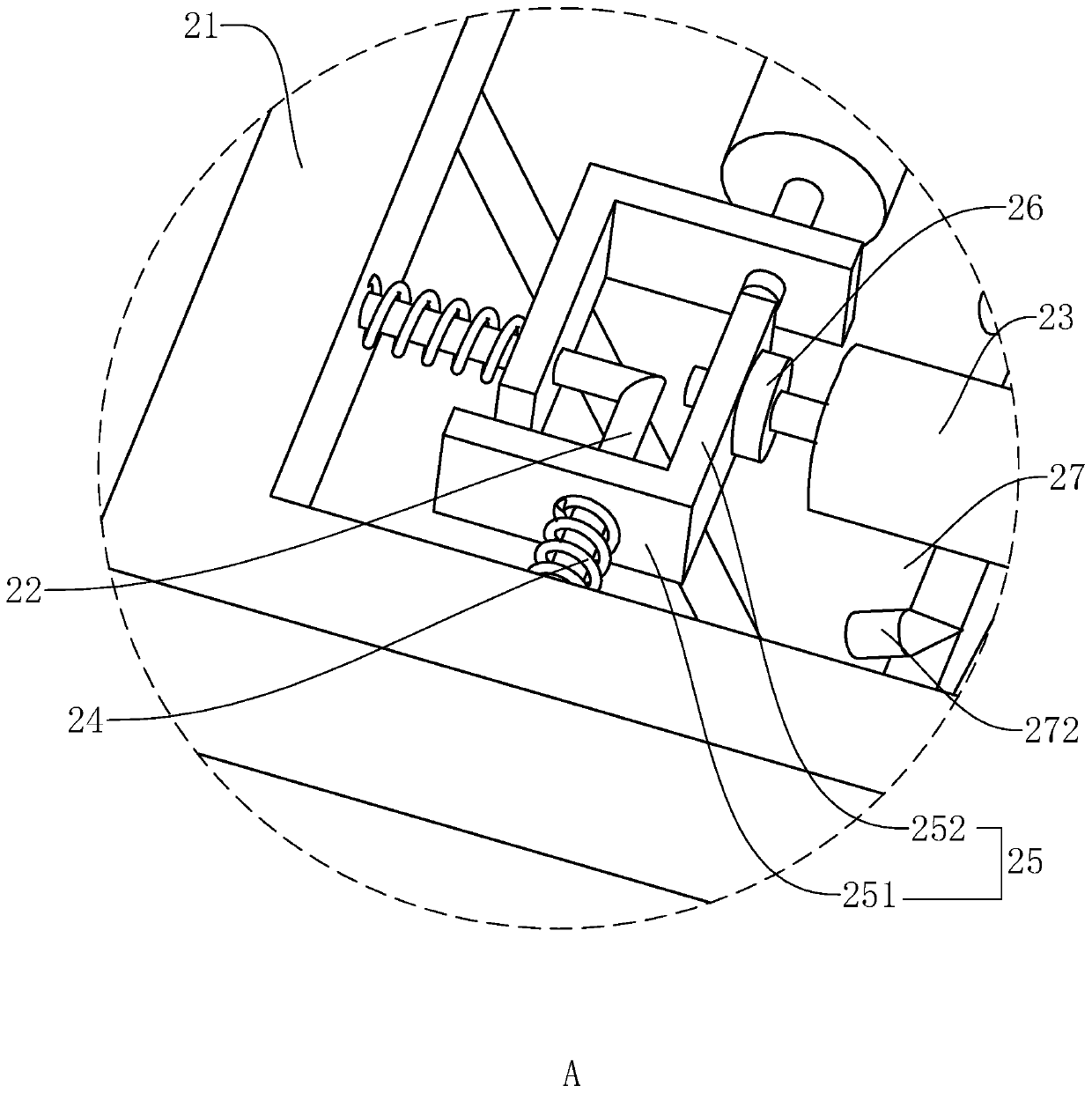

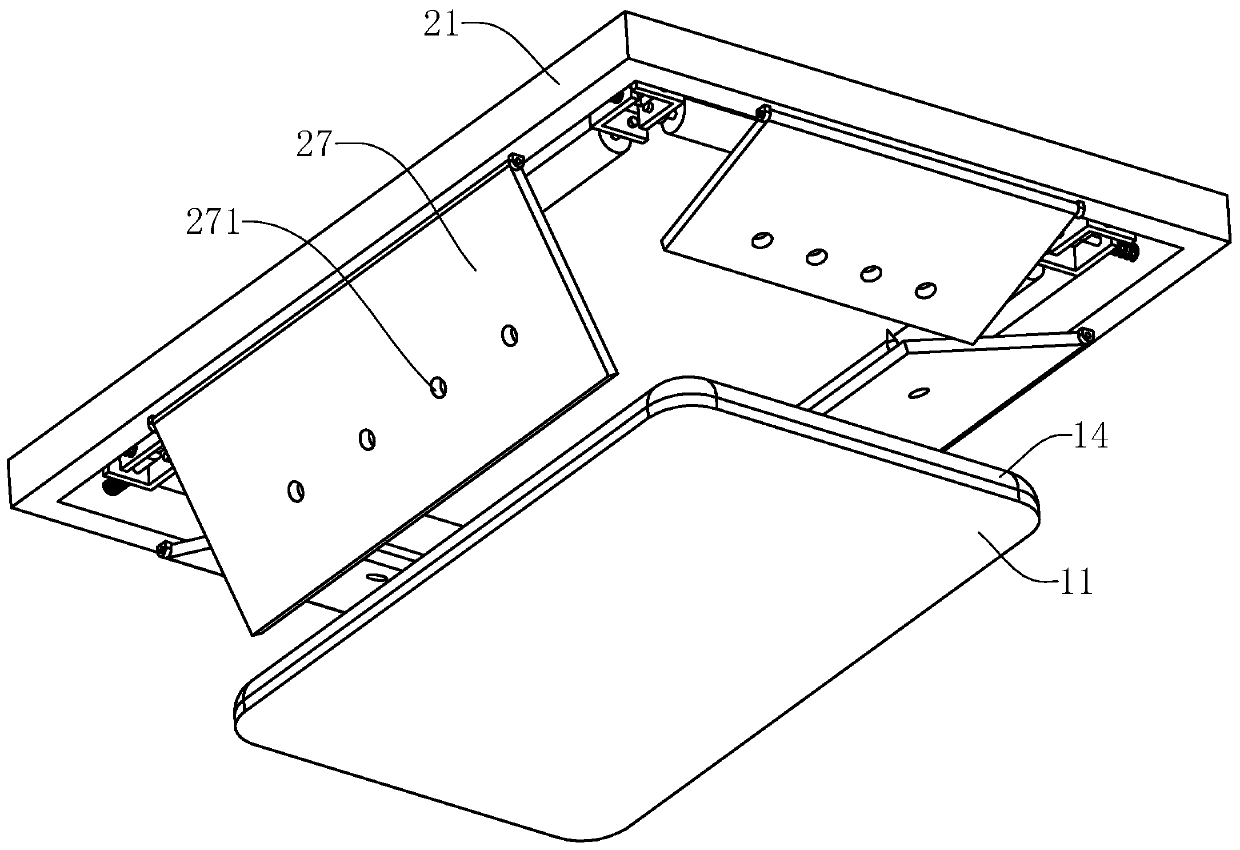

[0047] S22. Place the bottom plate 11 downwards and place it horizontally, cover the fixed frame 21 on the top of the edge banding strip 14 from top to bottom, gradually press down the fixed frame 21, and use the pressure roller 23 to tension and flatten the fabric downward, so that the fabric is flat On the outer side of the edge strip 14 and above the filling layer 12;

[0048] S23 , grabbing the corner of the fabric below the bottom plate 11 and pulling the fabric...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com