A superplastic forming device and process for a metal bipolar plate of a proton exchange membrane fuel cell

A technology of metal bipolar plates and proton exchange membranes, applied in battery electrodes, circuits, electrical components, etc., can solve problems such as high processing costs and complex forming processes, and achieve low residual stress, uniform plate thickness, and high elongation Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

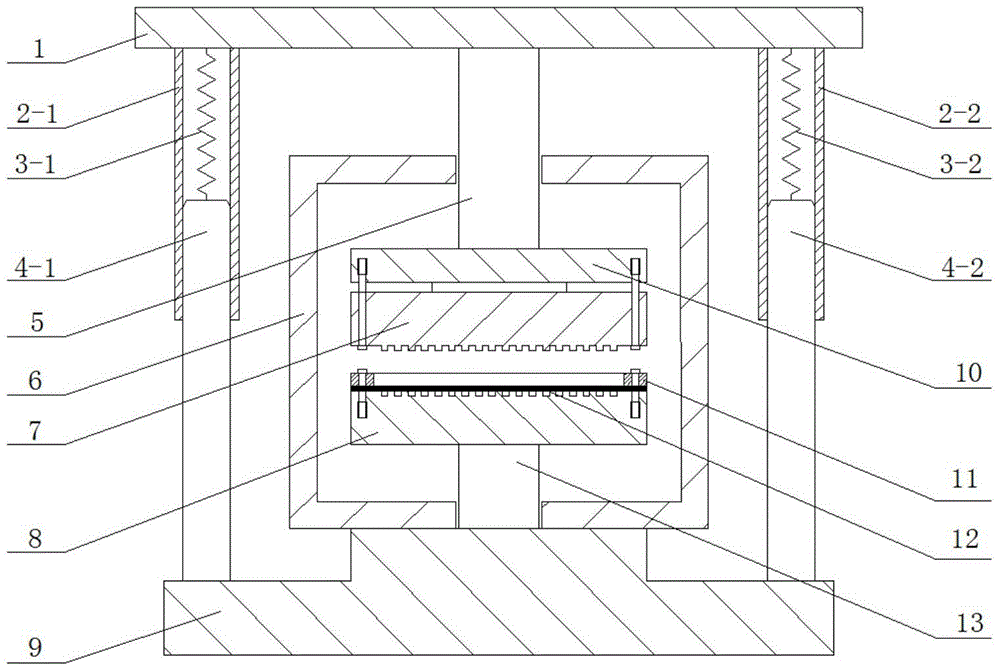

[0031] In combination with the accompanying drawings in the description, taking the superplastic forming of a TC21 titanium alloy bipolar plate as an example, the specific implementation process of the present invention is further described.

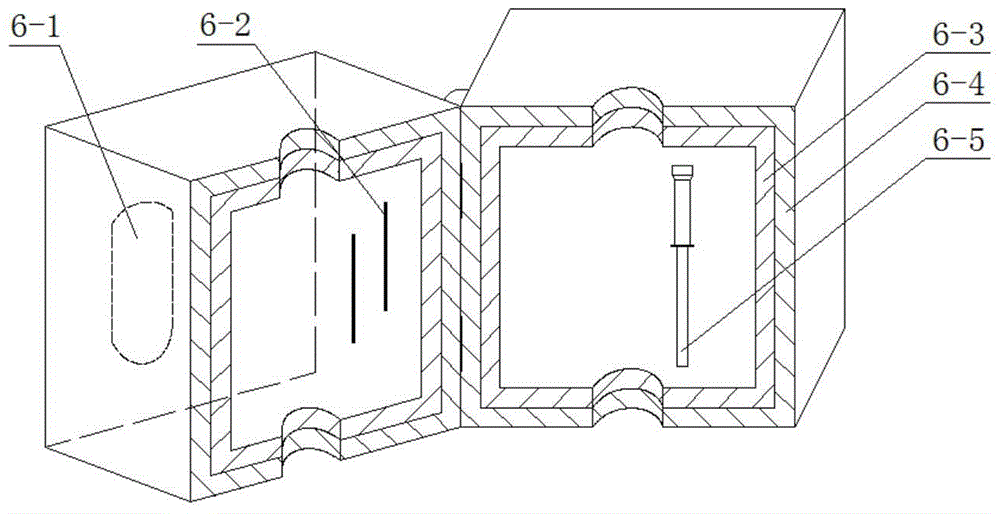

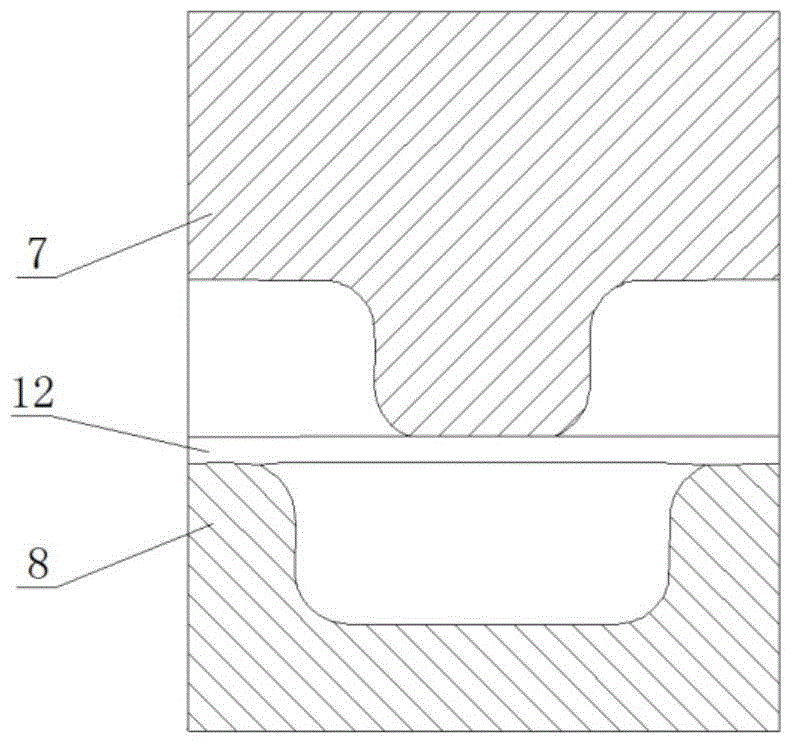

[0032] Such as figure 1 , figure 2 As shown, a superplastic forming device for a metal bipolar plate of a proton exchange membrane fuel cell is installed on the workbench of a pressure forming machine and connected with a circuit system, and consists of a pressing plate 1, a guide sleeve A2-1, and a guide sleeve B2-2 , spring A3-1, spring B3-2, guide post A4-1, guide post B4-2, pressure rod 5, environment box 6, upper template 7, lower template 8, base 9, connecting plate 10, edge holder Plate 11, metal plate 12 and support rod 13 constitute.

[0033] The base 9 and the pressure plate 1 are correspondingly matched rectangular rigid bodies. A boss is set at the center of the base 9, and the guide post A4-1 and the guide post B4-2 are r...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com