A system to solve the springback phenomenon in the process of laying up composite materials

A composite material and phenomenon technology, applied in the field of automatic laying of composite materials, can solve the problems of affecting the quality and efficiency of laying, violation of automatic laying, waste of resources, etc., so as to improve the quality and efficiency of laying, and solve the problem of Bullet phenomenon, the effect of reducing manpower

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

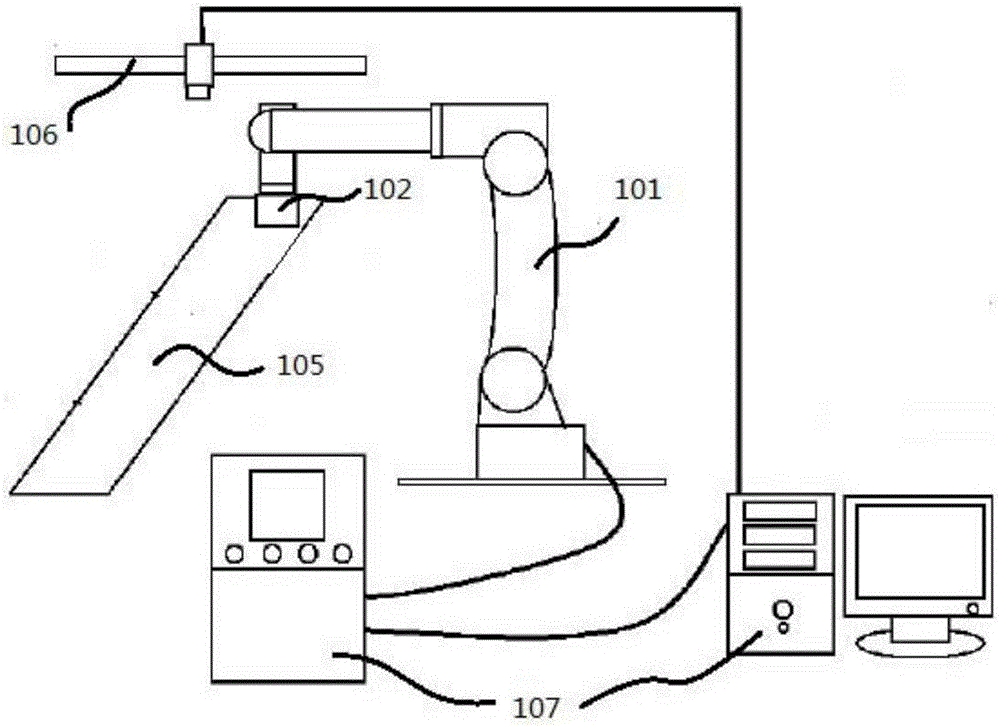

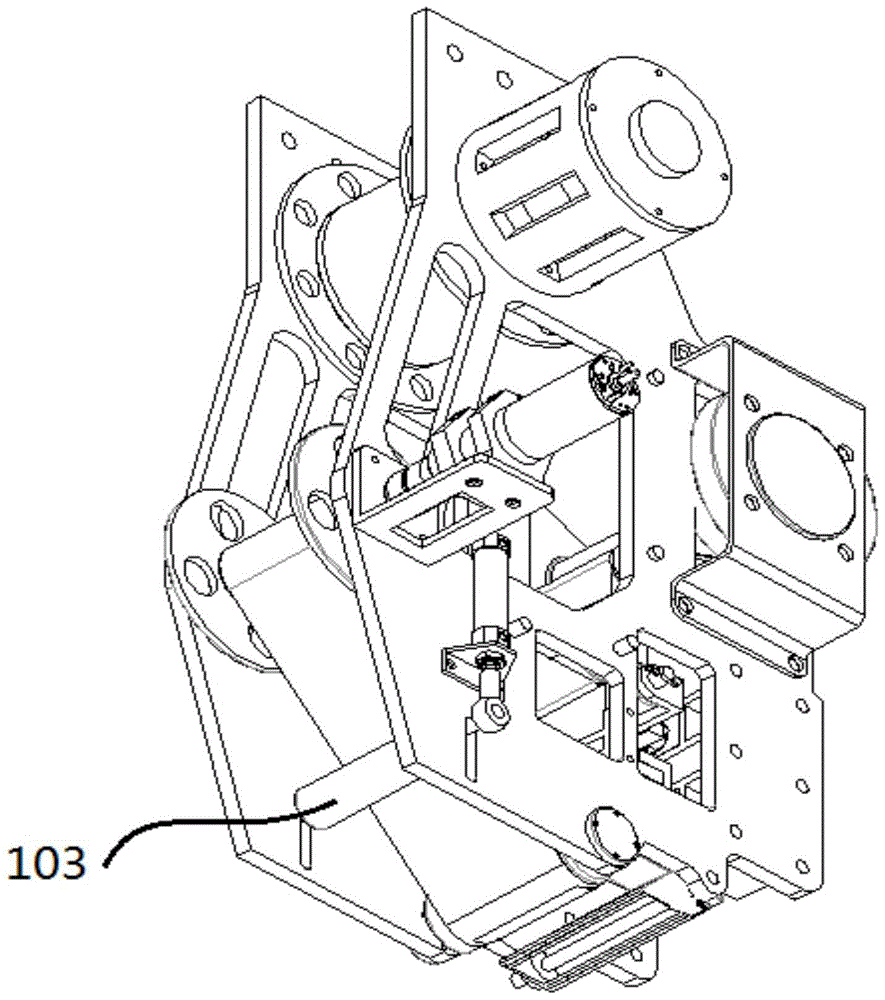

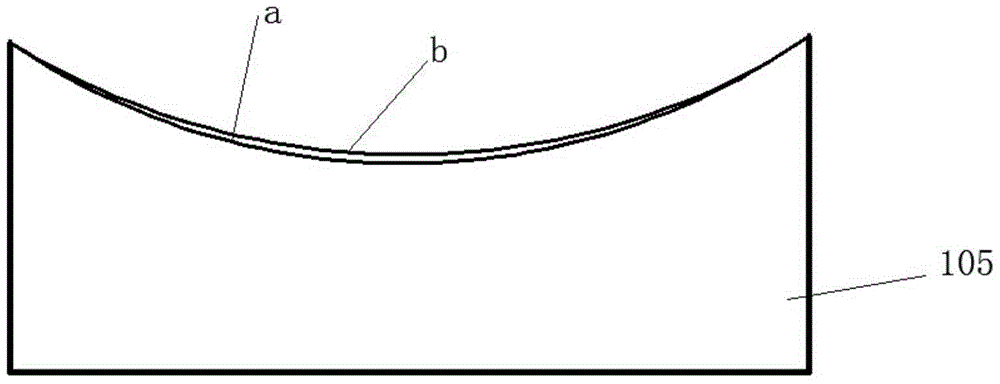

[0025] figure 1 It is a schematic diagram of the overall structure of the whole system of the present invention. The torque / force sensor located at the connection between the end of the six-axis robot and the tape laying head detects the laying pressure of the main pressure roller in real time; the three-dimensional shape measurement system 106 gives real-time feedback to the contour of the workpiece 105, and then sends a signal through the main controller to control such as Figure 4 The operation of the auxiliary heating system 104 and the auxiliary compaction device 103 is shown.

[0026] First, the tape laying head 102 is laid according to a predetermined trajectory driven by the six-axis robot 101. At the same time, the torque / force sensor connected to the end of the robot and the laying head detects the pressure of the main laying roller on the laying head in real time. And transmit the signal to the control system. After receiving the signal, the control system compar...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com