Multiple hot pressing equipment for nonwoven fabric processing

A hot-pressing equipment, non-woven technology, applied in textiles and papermaking, fabric surface trimming and other directions, can solve problems such as overall mechanical properties to be improved, low structural strength of non-woven fabrics, damage to the internal structure of fibers, etc. The effect of avoiding the rebound phenomenon and reducing the moisture content

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

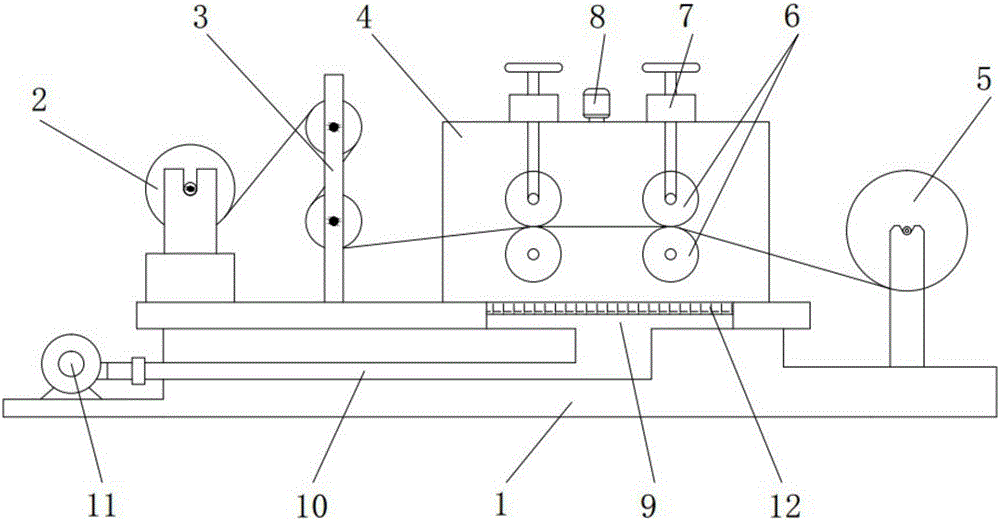

[0019] The multiple hot pressing equipment for non-woven fabric processing of the present invention includes: a base 1 on which a discharge roller 2, a leveling adjustment mechanism 3, a hot pressing chamber 4, and a roll are sequentially arranged from left to right. Material roller 5; when the non-woven fabric is processed, pass through the above-mentioned mechanism in turn; among them, the flattening adjustment mechanism 3 is provided with two upper and lower pressure rollers to ensure that the non-woven fabric is fully adjusted and flattened; the hot pressing chamber 4 is side by side There is a set of hot pressing rollers 6; the set of hot pressing rollers 6 is connected with a height adjustment mechanism 7 arranged at the top of the hot pressing chamber 4; figure 1 As shown, the height adjustment mechanism 7 is provided with a hand wheel above the height adjustment mechanism 7, and the screw is driven by the rotating hand wheel to pull the hot pressing roller set to move up...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com