Full-automatic slotting bending machine

A fully automatic, bending machine technology, applied to other manufacturing equipment/tools, metal processing equipment, feeding devices, etc., can solve the problems of small application range, low control precision, low production efficiency, etc., to avoid interference , broad application prospects, good product precision effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

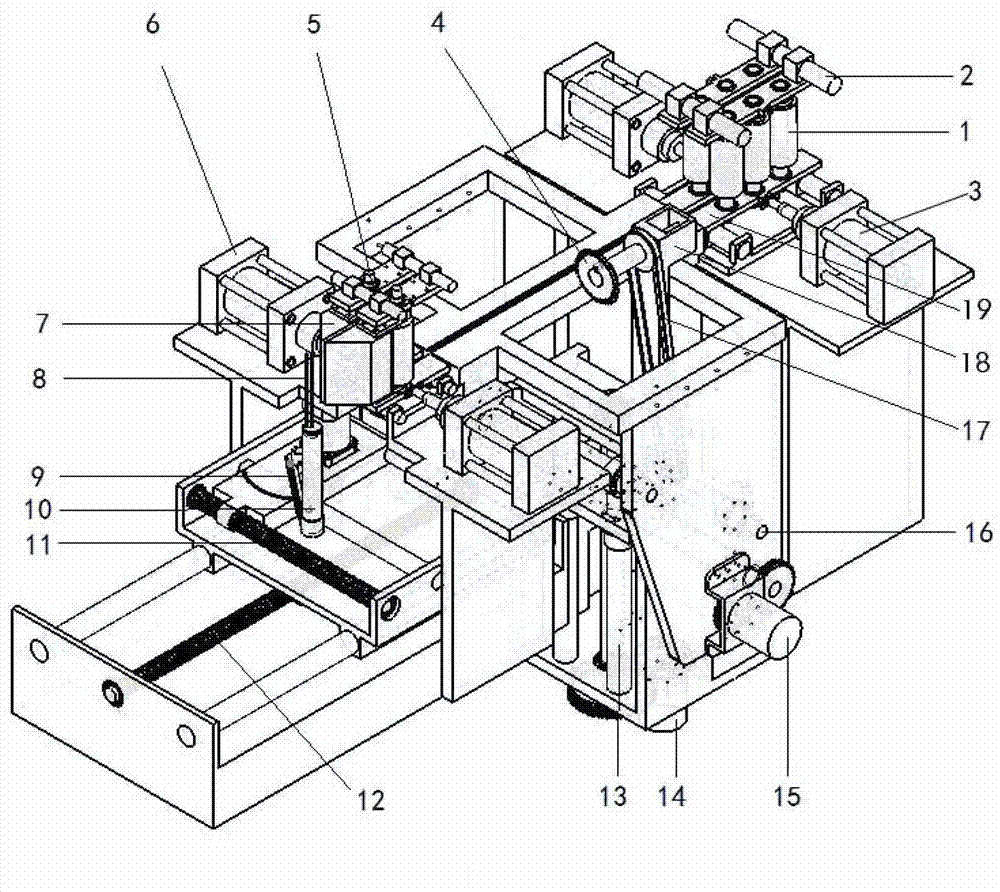

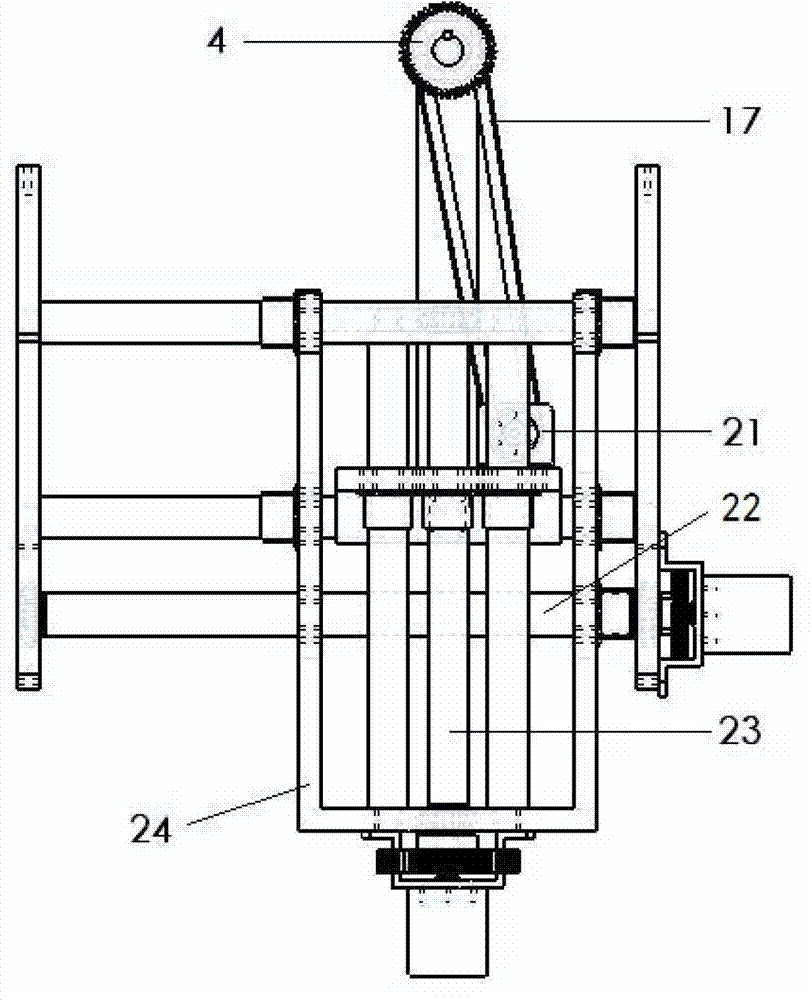

[0038] like figure 1 As shown, a fully automatic slotting and bending machine includes a base (not shown) and a feeding mechanism, a slotting mechanism and a bending mechanism sequentially arranged on the base.

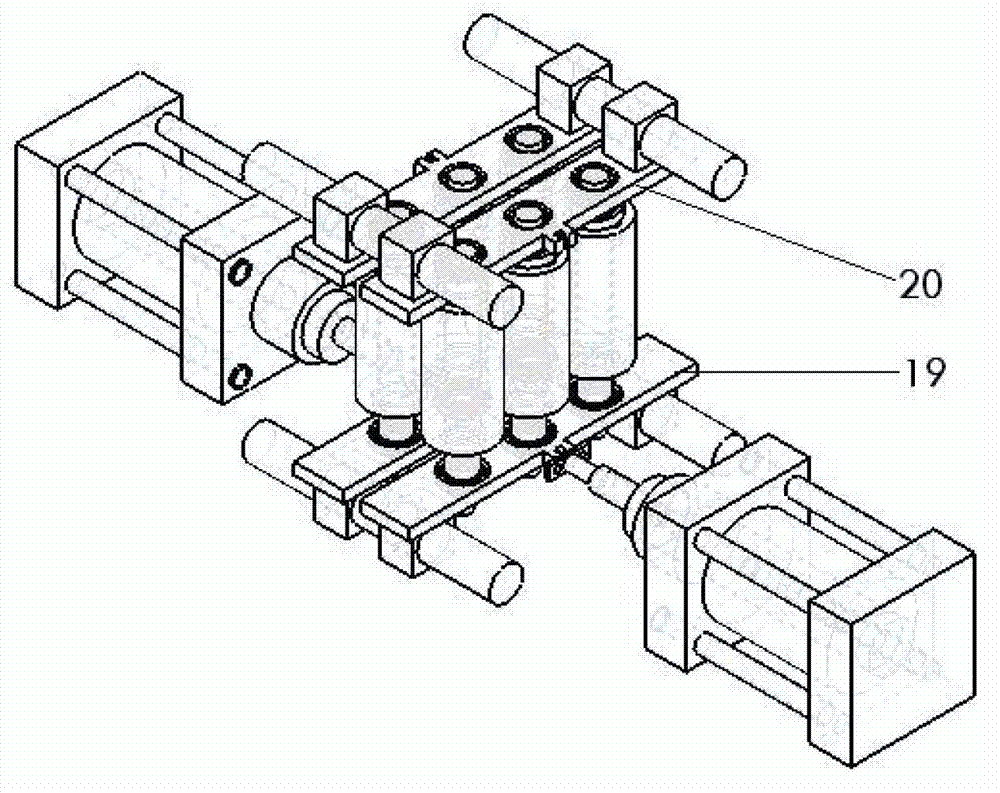

[0039] like figure 1 and figure 2 As shown, the feeding mechanism includes two parts symmetrically arranged, and each part includes a feeding clamping cylinder 3, a lower supporting plate 19 fixedly arranged on the piston rod of the feeding clamping cylinder 3, a row of vertical feeding rollers 1 and an upper supporting plate 20. The upper and lower ends of a row of vertical feed rollers 1 are respectively installed on an upper support plate 20 and a lower support plate 19, an upper support plate 20 and a lower support plate 19 form a feeding mechanism support frame, a row of vertical Feed roller 1 is all rotationally matched with upper support plate 20 and lower support plate 19, and a row of vertical feed rollers 1 includes 3 vertical feed rollers arranged in a s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com