Pipe semi-solid air pressure contact forming method

A thixoforming, semi-solid technology, used in forming tools, metal processing equipment, manufacturing tools, etc., can solve the problem that the yield strength and thickness of the pipe should not be too high, the material with poor plasticity cannot be used, and it is not suitable for forming complex shapes. Parts and other problems, to achieve the effect of reduced deformation resistance, strong filling, and low tonnage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

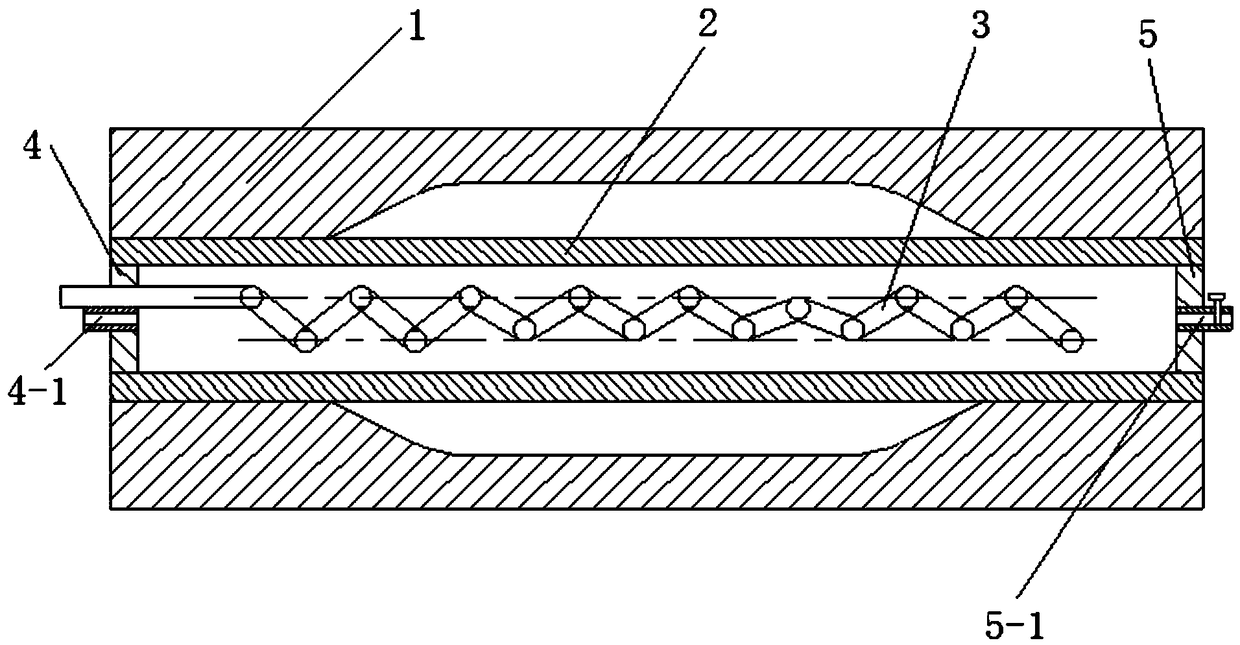

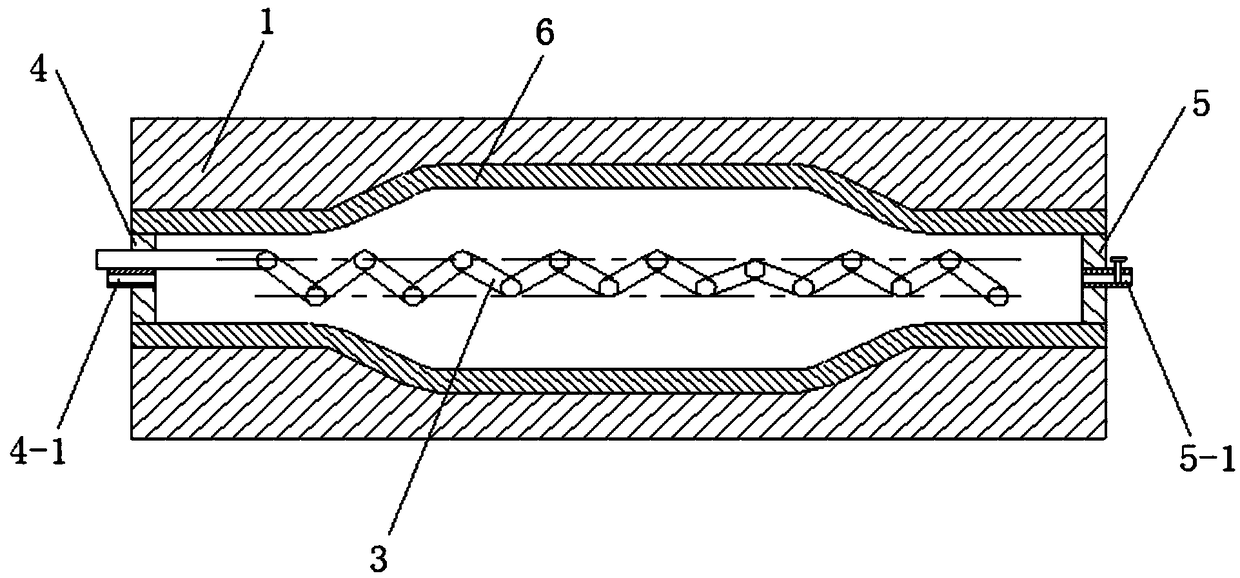

[0023] Specific implementation mode 1: A semi-solid gas pressure thixotropy forming method for pipes in this implementation mode is carried out according to the following steps:

[0024] 1. Place the pipe in the cavity of the forming mold and close the mold, and then use the sealing plug with gas injection port and the sealing plug with gas output port to seal the inside of the pipe;

[0025] The thickness of the pipe is 1 mm to 10 mm;

[0026] 2. Heat the pipe to the semi-solid temperature, and keep warm when the solid phase volume percentage inside the pipe is 75% to 90%, and keep warm for 1min to 2min for every 1mm thick pipe;

[0027] 3. Continuously inject gas with a pressure of 90MPa to 150MPa into the pipe through the gas injection port until the outer wall of the pipe fits the mold cavity;

[0028] 4. Stop the heating of the pipe and open the valve of the gas output port at the same time to discharge the gas;

[0029] 5. Open the forming mold, take out the formed pip...

specific Embodiment approach 2

[0035] Embodiment 2: This embodiment differs from Embodiment 1 in that the pipes described in step 1 are aluminum alloy pipes, titanium alloy pipes, magnesium alloy pipes or steel pipe fittings. Others are the same as in the first embodiment.

specific Embodiment approach 3

[0036] Embodiment 3: This embodiment differs from Embodiment 1 or Embodiment 2 in that: the thickness of the pipe described in step 1 is 5 mm to 10 mm. Others are the same as in the first or second embodiment.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com