Screening device for sponge sand production

A screening device, sponge sand technology, applied in the directions of transportation and packaging, conveyor objects, etc., can solve the problems of increasing the workload of operators, improving the labor intensity of operators, etc., to improve the orderliness of placement, reduce labor intensity, The effect of avoiding the rebound phenomenon

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0036] The present invention will be described in further detail below in conjunction with the accompanying drawings.

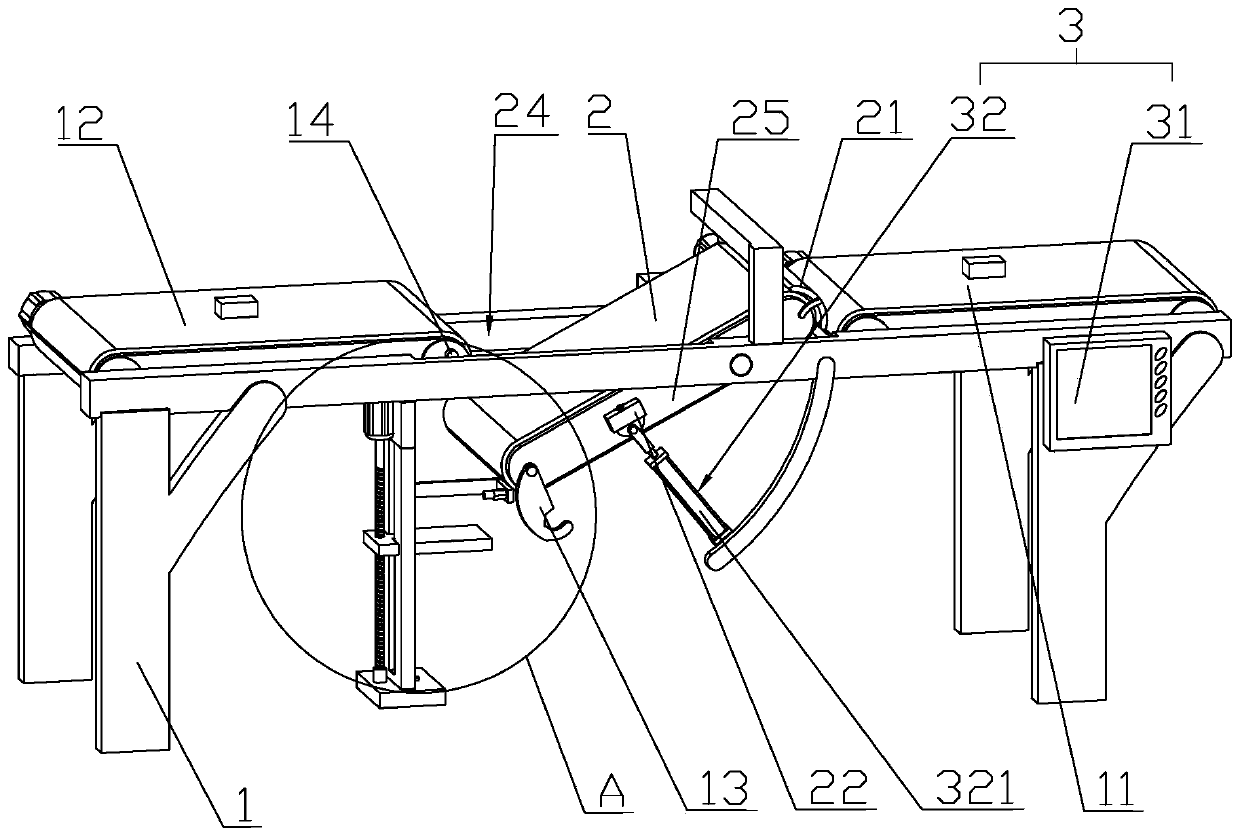

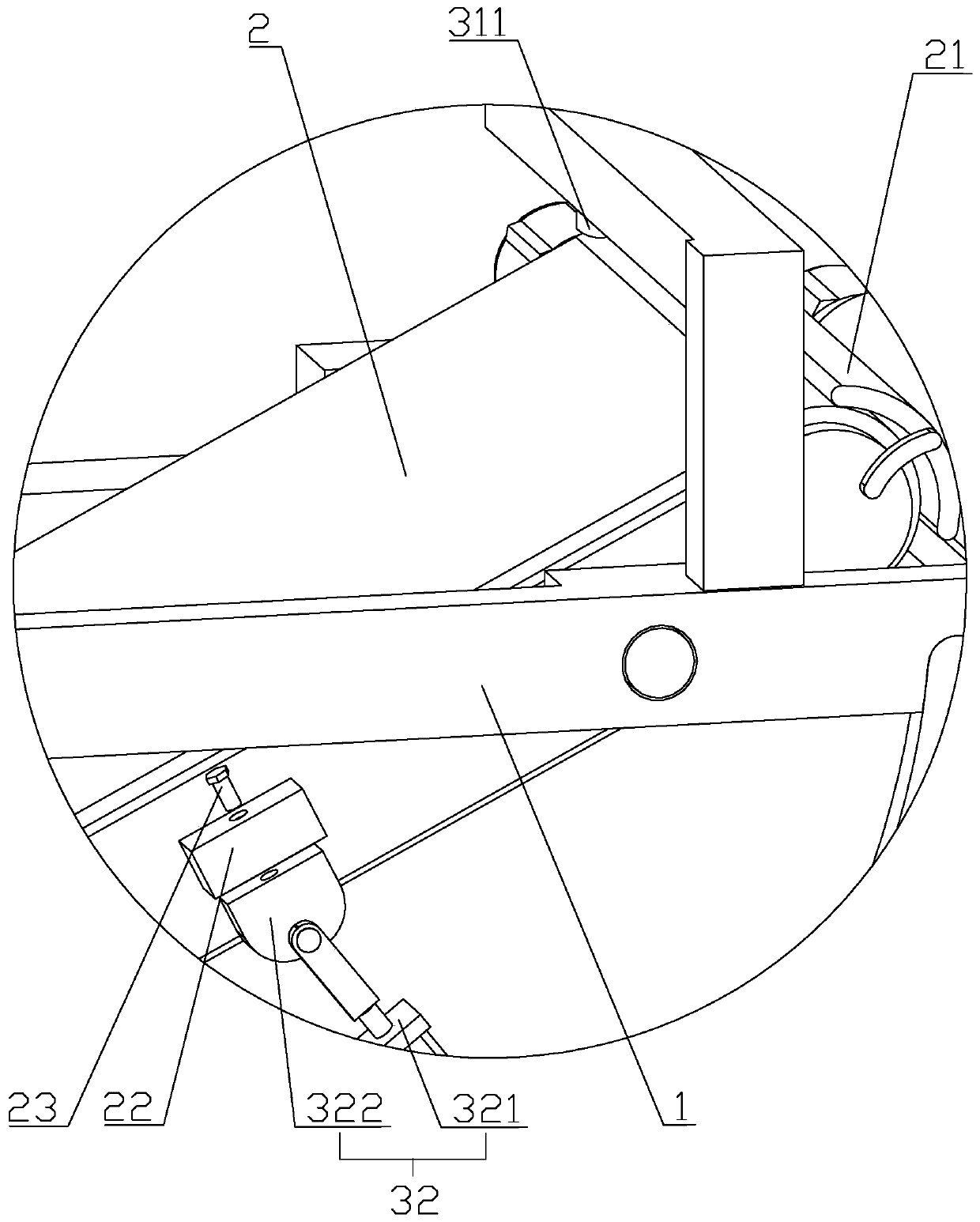

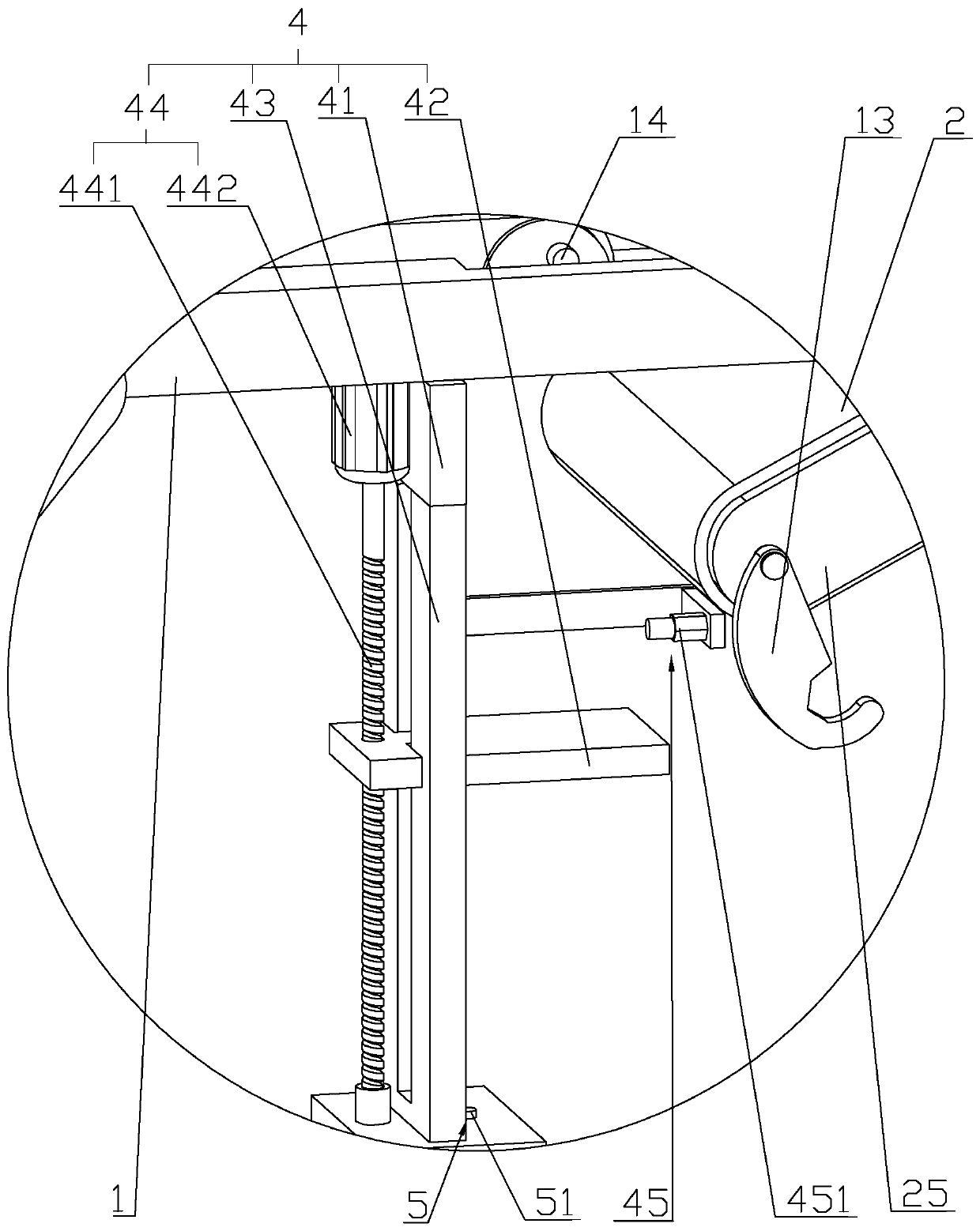

[0037] refer to figure 1, is a screening device for sponge sand production disclosed in the present invention, including a machine body 1, an adjustment guide belt 2 arranged on the machine body 1, an output guide belt 12 arranged on the machine body 1, and a belt for use on the machine body 1. Identification component 3 for identifying defective products and finished products. The conveyor belt 11 for transporting sponge sand is located on one side of the machine body 1, and the adjustment guide belt 2 is located between the outlet of the conveyor belt 11 and the inlet of the output guide belt 12, and the finished sponge sand is transferred from the conveyor belt 11 to the adjustment guide. The tape 2 finally transitions to the output guide tape 12 to continue packaging and other processes. The adjustment guide belt 2 includes a base 25, a belt rollingly c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com