Material mechanical performance measurement device and pressing head assembly and measurement method thereof

A technology of mechanical properties and indenters, which is applied in the field of measuring devices for mechanical properties of materials, can solve the problems of low precision, inaccurate test results, and inability to form portable and instrumented testing equipment, so as to achieve improved accuracy, accurate data, The effect of improving detection accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

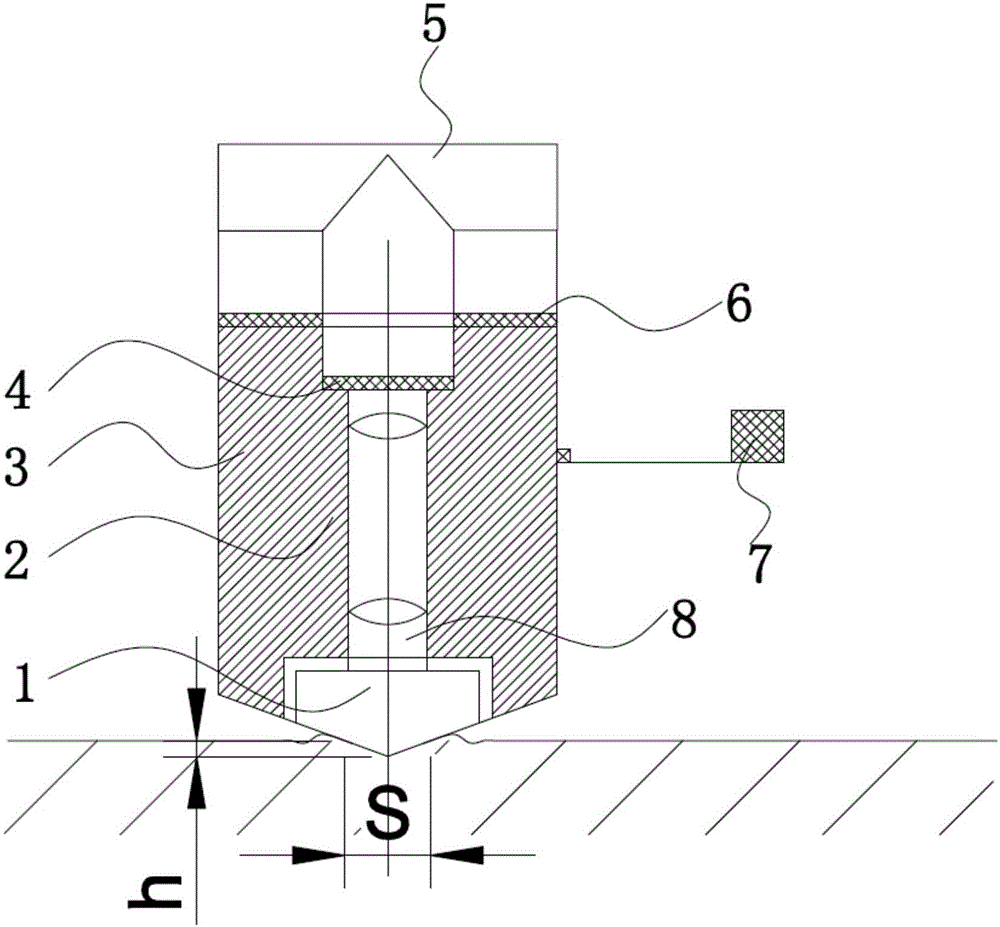

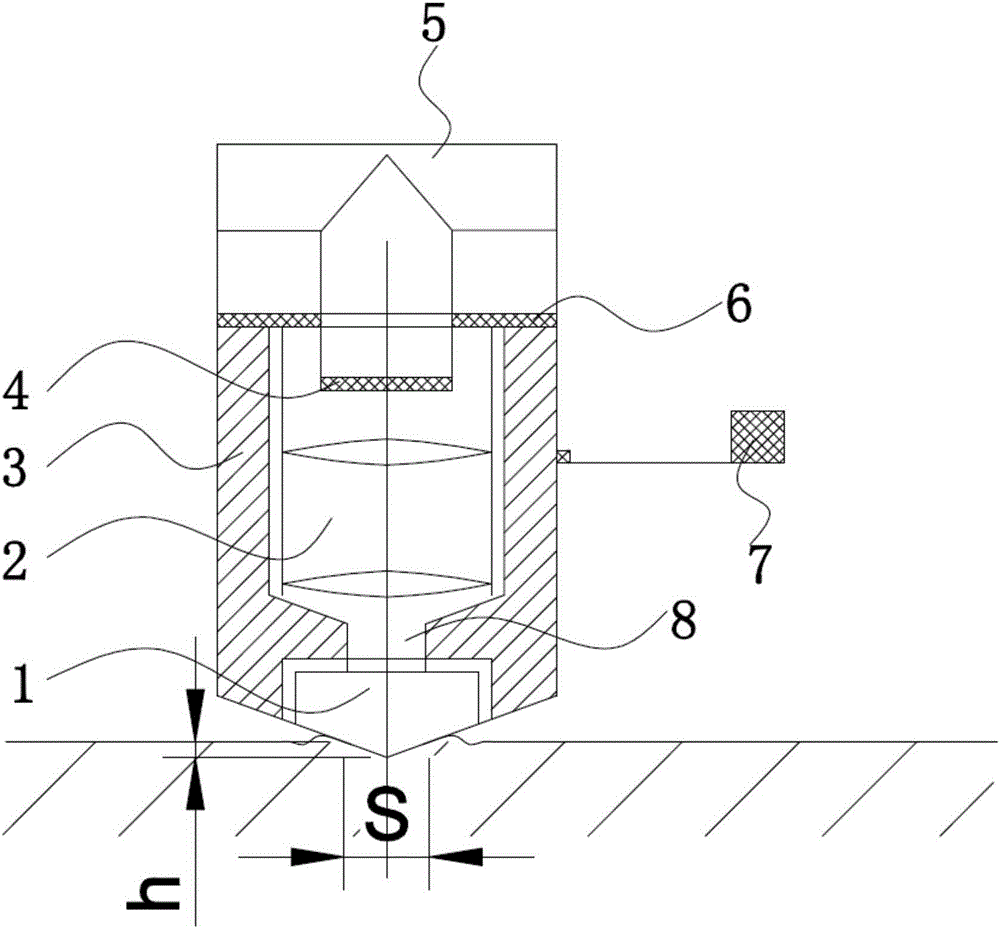

[0037] This embodiment proposes an indenter assembly for measuring the mechanical properties of materials, such as figure 1 and figure 2 As shown, it includes: an indenter 1 and an indenter rod 3 for applying pressure on the measured object to obtain an indentation, a sensor assembly for obtaining the pressure and depth of the indenter 1, and a sensor assembly for obtaining the indentation The image of the indentation and the optical assembly of the deformed size data of the measured object; wherein, the indenter rod 3 is a hollow structure, the optical assembly is arranged on the indenter rod 3, and the indenter 1 is made of a transparent material It is arranged at the end of the indenter rod 3 , and the optical imaging path of the optical assembly is consistent with the pressing direction of the indenter 1 .

[0038]The indenter assembly for measuring the mechanical properties of materials proposed in this embodiment is composed of an indenter rod 3, an indenter 1 and an o...

Embodiment 2

[0044] This embodiment proposes a device for measuring mechanical properties of materials, such as Figure 1-2 As shown, it includes a base, a column and a cantilever 5, a display screen arranged on the cantilever 5, a press plate test bench arranged on the base, the base, a column and the cantilever 5 are fixedly connected in sequence, and also includes a display screen arranged on the cantilever 5. The indenter for testing the mechanical properties of materials as described in Embodiment 1 on the above-mentioned cantilever 5.

[0045] The material mechanical property detection device proposed in this embodiment uses the above-mentioned material mechanical property detection indenter to measure the material mechanical property, so it has better accuracy than the existing detection device.

Embodiment 3

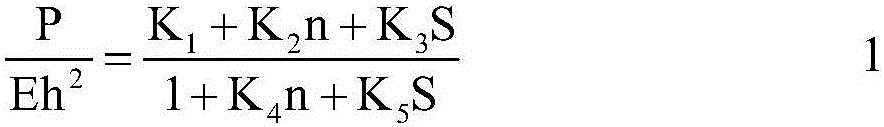

[0047] This embodiment proposes a method for measuring the mechanical properties of materials, which is measured by using the device for measuring mechanical properties of materials in the above-mentioned embodiment 2. The loading pressure drives the indenter through the indenter rod to depress the indenter in multiple times at equal depths, including:

[0048] S1: Pressing in to a predetermined depth h to stop pressing down, and stabilizing time t, measure the pressure P1, indentation depth h1 and indentation area S1 of the indenter 1 at this time, until all data are measured, and then execute step S2;

[0049] S2: unloading half of the indentation depth, the stabilization time t, measure the pressure P2, indentation depth h2 and indentation area S2 of the indenter 1 at this time, until all the data are measured, and execute step S3;

[0050] S3: press again to the predetermined depth h to stop pressing down, stabilize time t, measure the pressure P3, indentation depth h3 and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com