Fully water lubricating and end flow distributing pure water hydraulic axial plunger pump or motor

An axial plunger pump, water lubrication technology, applied to the components of the pumping device for elastic fluid, fluid pressure actuating device, pump and other directions, can solve the difficulty of stepless variable, difficult rotating speed and poor self-priming and other problems, to achieve the effect of improving work reliability and service life, light weight and short length

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

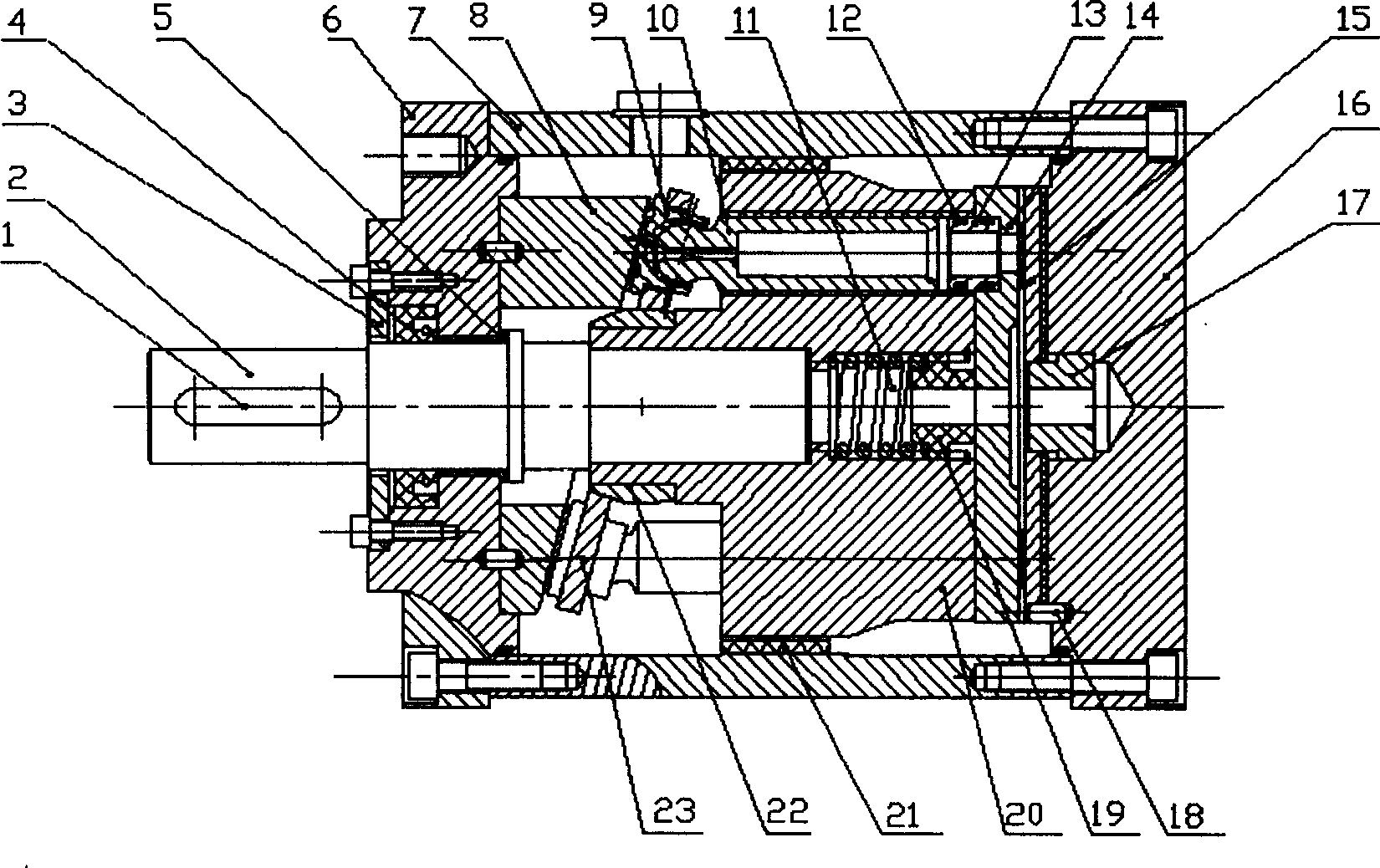

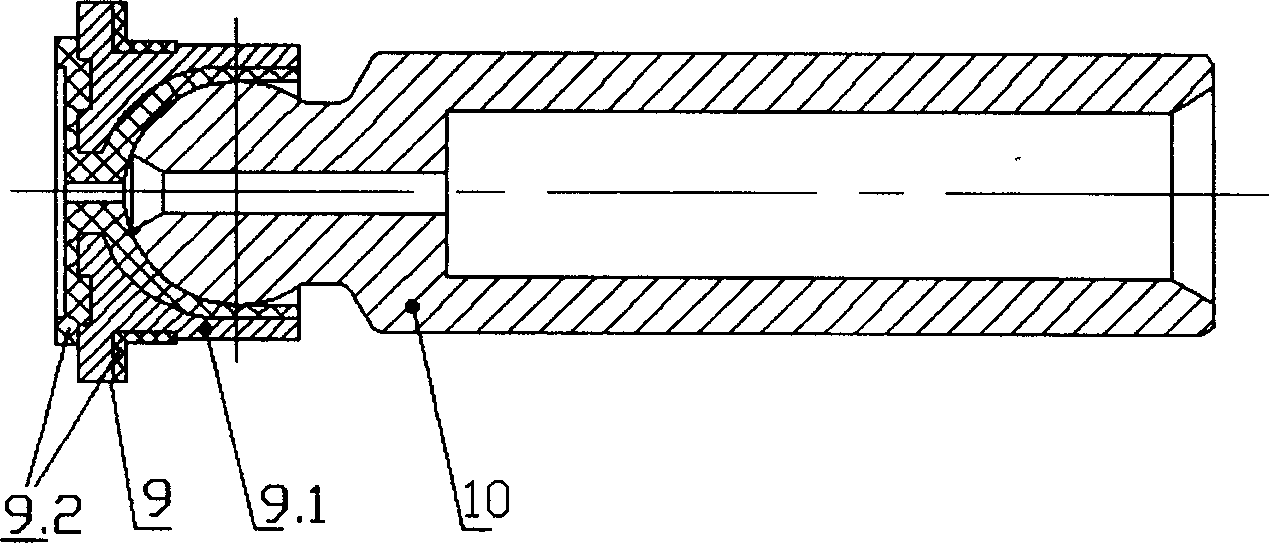

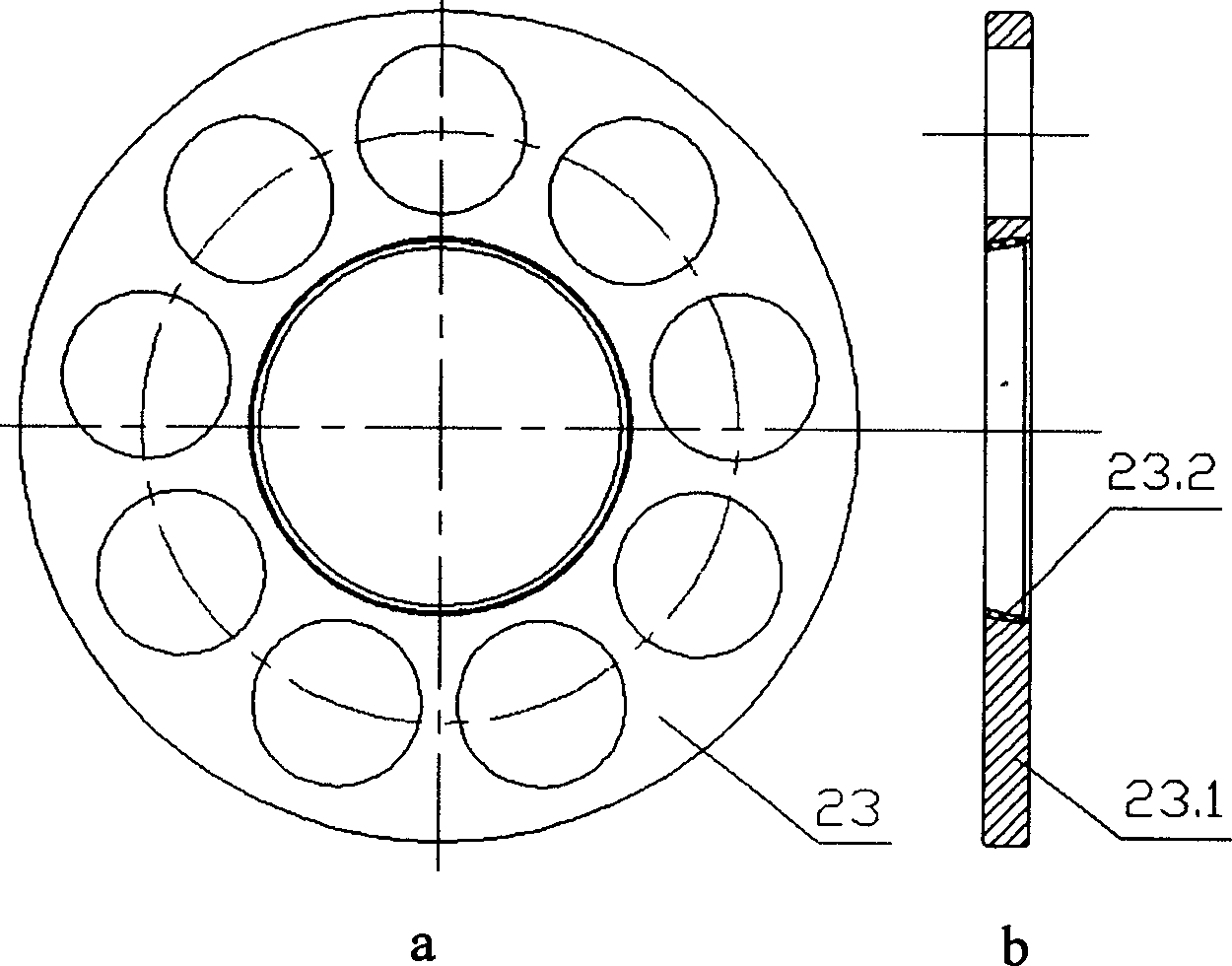

[0024] Such as Figure 1 to Figure 4 As shown, the present invention consists of a shell (including a left end cover 6, a right end cover 16, and a housing 7) and a rotatable cylinder 20 installed in the shell. Cylinder holes parallel to the axis of the cylinder body 20 are evenly distributed on the same circumference of the cylinder body 20. The plunger 10 of the plunger shoe assembly is placed in the cylinder hole, and the inner wall of the cylinder hole is firmly combined with reinforced plastic, which is made of stainless metal material The plunger 10 is made into a plunger pair. On the right side of the cylinder block 20 is the thrust plate 14 . The central spring 11 placed in the center of the cylinder body 20 compresses the sliding shoe 9 and the swash plate 8 of each plunger shoe assembly through the cylinder body, the ball joint 22 and the return plate 23 . The other end of the central spring 11 presses the thrust plate 14 to the flow plate 15 by pressing the plasti...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com