Two-dimensional dual axial piston pump

A double-coupling and piston pump technology, applied in the field of hydraulic pumps and hydraulic motors, can solve the problems of high processing and maintenance requirements, high cost, fast cylinder temperature rise, and limited displacement, so as to simplify the overall structure and eliminate flow pulsation , The effect of eliminating torque ripple

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

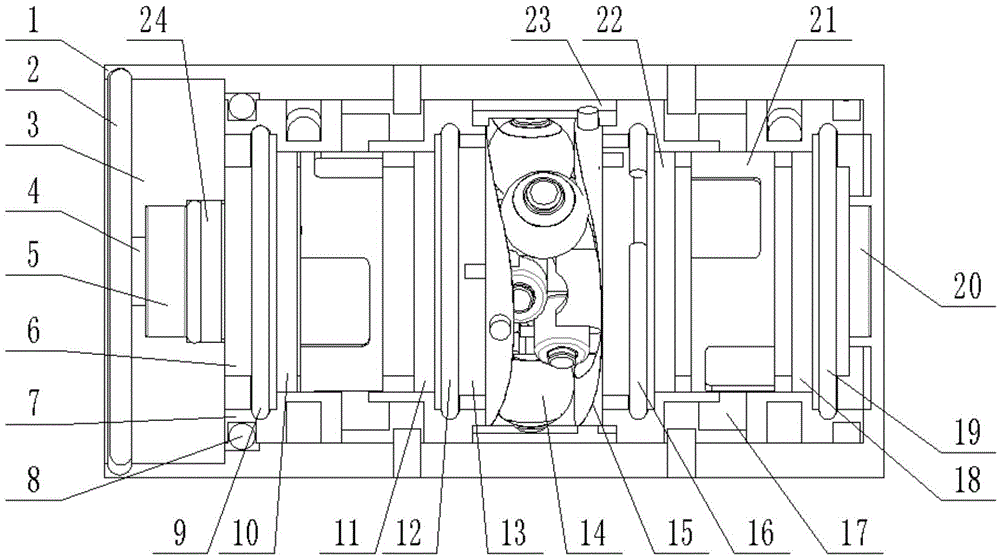

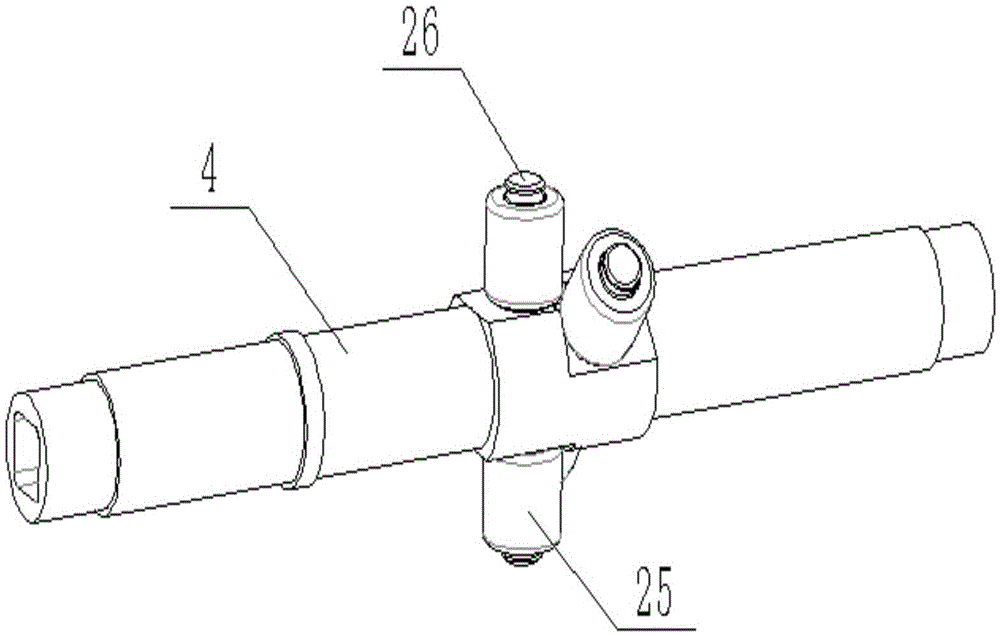

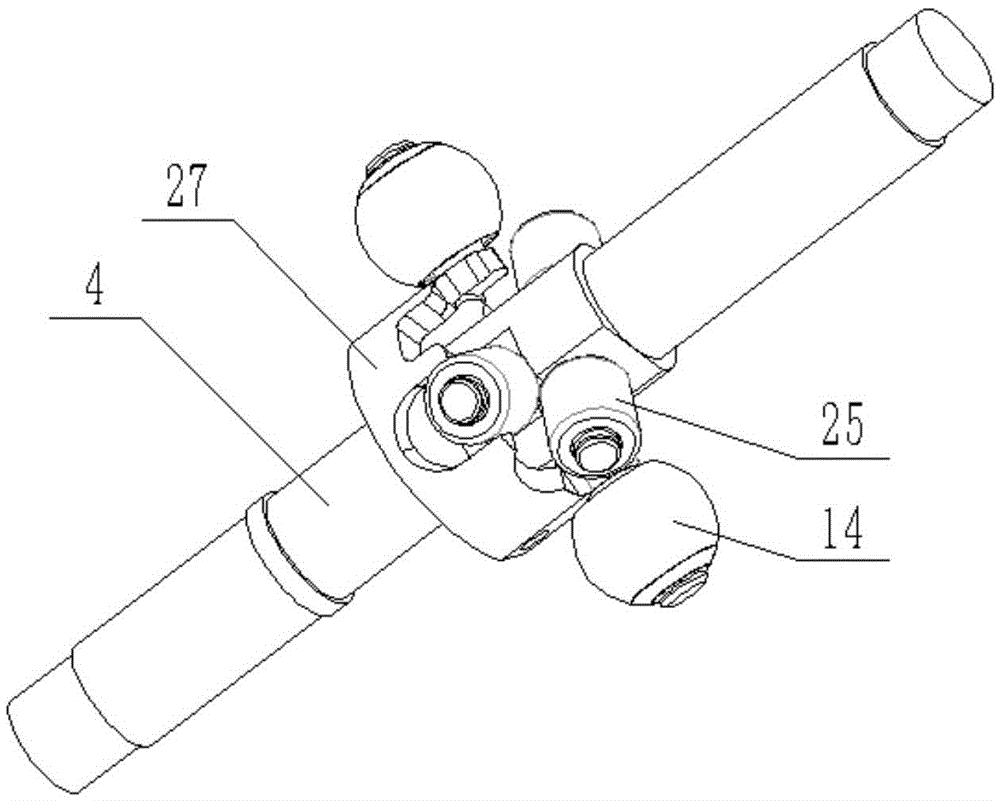

[0031] refer to Figure 1 to Figure 7 , two-dimensional dual axial piston pump, including housing 1, left cylinder 7, right cylinder 17, left piston 6 and right piston 21, left cylinder 7 and right cylinder 17 are placed in the housing through positioning steel ball 8 1 and is fixedly connected with the housing 1 through the connecting sleeve 23. The housing 1 is provided with an oil suction and discharge hole and a leakage oil return channel. The left end of the housing 1 is fixed with a left end cover 3. The left cylinder 7 The left end of the right end and the right cylinder body 17 is respectively fixedly connected with the left equal addition and subtraction curved surface track 13 and the right equal addition and equal subtraction curved surface track 15 with the same rolling surface, and the left equal addition and equal subtraction curved surface track 13 and the right equal addition and equal subtraction curved surface The orbits 15 are staggered by 90 degrees, that i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com